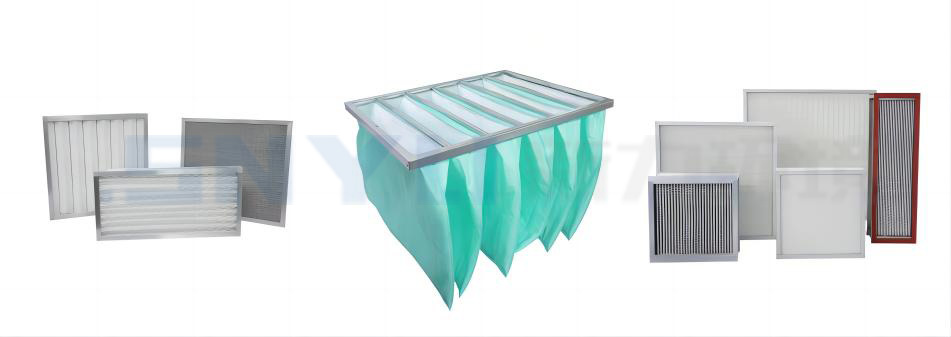

What is Industrial Air Filter

Industrial air filter is the equipment used in the industrial production process to remove solid particles, impurities and pollutants in the air. They play a vital role in ensuring product quality, prolonging equipment life and improving production efficiency, and are widely used in various fields, including chemical, pharmaceutical, food processing, electronic manufacturing, to ensure the smooth progress of production process and high quality of products.

Main uses of industrial air filters

1. Remove impurities: the filter can effectively remove solid particles, impurities and pollutants in the air, and maintain the air quality. |

2. Protection equipment: by removing the impurities in the air, the filter can protect the equipment, prolong its service life, and reduce the maintenance cost. |

3. Improve the product quality: the air filter can effectively reduce the impact of the pollutants in the air on the product production process, and improve the yield. |

4. Improve production efficiency: by improving air cleanliness, production efficiency can be effectively improved to reduce equipment failure and downtime. |

Features of the air filters

1. Efficient filtration: it can effectively remove dust, particles and pollutants in the air, and provide clean air. |

2. A variety of filter materials: synthetic fiber, glass fiber and activated carbon are often used to meet different filtration needs. |

| 3. Widely used: widely used in air conditioning system, ventilation system and air purification equipment. |

Application field of industrial air filters

1. Chemical industry: used to remove impurities and pollutants in the air in the chemical production process, to ensure product quality and production efficiency. |

2. Pharmaceutical industry: it is used to remove impurities and pollutants in the air in the pharmaceutical process to ensure the purity and safety of drugs. |

3. Food processing: used to remove impurities and pollutants in the air in the process of food processing, to ensure the safety and quality of food. |

4. Electronic manufacturing: used to remove impurities and pollutants in the air in the process of electronic manufacturing, to ensure the quality and performance of electronic products. |

Maintenance and upkeep of industrial air filters

Maintenance methods |

1. Regular inspection and cleaning: regularly check the status of the filter, clean the dust and impurities on the filter material surface, and maintain its efficient filtration performance. |

2. Timely replacement: according to the use environment and the specific situation, replace the filter in time to ensure the filtration effect. Filter replacement intervals can also be determined based on final resistance data. |

3. Check the sealing: check the sealing of the filter regularly to ensure that there is no leakage and ensure the filtration effect. |

Upkeep Methods |

1. Regular maintenance to maintain its efficient operation. |

2. Correct use: use the filter correctly according to the instructions to avoid overload operation and improper operation. |

| 3. Storage environment: the filter should be stored in a dry and ventilated environment to avoid moisture and pollution. |

Notes for selecting industrial air filters

1. Filtration efficiency: according to the use environment and the cleanliness requirements of the air, select the appropriate filtration efficiency to ensure that it can effectively remove impurities and reach the due filtration level.

2. Filter material and structure: according to the filter requirements, choose the appropriate filter material and structure.

3. Brand and quality: select well-known brands and high-quality filters to ensure their filtering effect and service life.

4. Price and service: considering the price of the filter and the service of the producer, choose the cost-effective products.

Abouts SNYLI

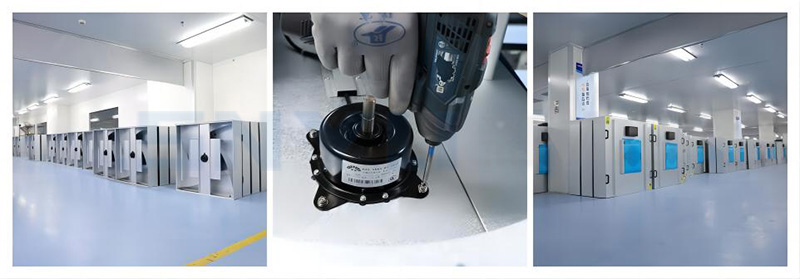

1. Strong production capacity and independent storage. Effectively meet the customer's demand for the production cycle.

2. Multiple clean workshops. Including FFU production workshop, HEPA filter production workshop, bag filter production workshop, etc.

3. Technical advantages. With its advanced technology and production equipment, SNYLI is able to provide high-quality products and customized solutions.

4. Quality assurance. Before leaving the factory, the products will be inspected accordingly, which can strictly control the product quality, ensure that the products meet the relevant standards and regulations, and provide customers with reliable filtering solutions.

5. Cost advantage. While guaranteeing the quality of the products, SNYLI as the source factory can offer more competitive price.

6. Faster response speed. As a factory, SNYLI can respond to customer needs faster and provide more rapid service and support.