What is a HEPA filter?

The HEPA filter is mainly used to capture 0.3um particles of dust and various suspended matters. It adopts ultra-fine glass fiber paper as filter material, aluminium foil as separator, and is glued with metal frame. It has the features of high filtration efficiency, low resistance and large dust capacity. HEPA filters can be widely used in the air conditioning terminal air supply of dust-free purification workshops in such industries as optical electronics, LCD manufacturing, biomedicine, precision instruments, beverage and food, PCB printing, and so on. Both HEPA and ULPA filters are used at the end of the clean room.

Types of HEPA filters

Its structural form can be divided into: mini pleat HEPA filter, deep pleat HEPA filter, large airflow HEPA filter, gel seal HPEA filter, high temperature resistant filter, etc.

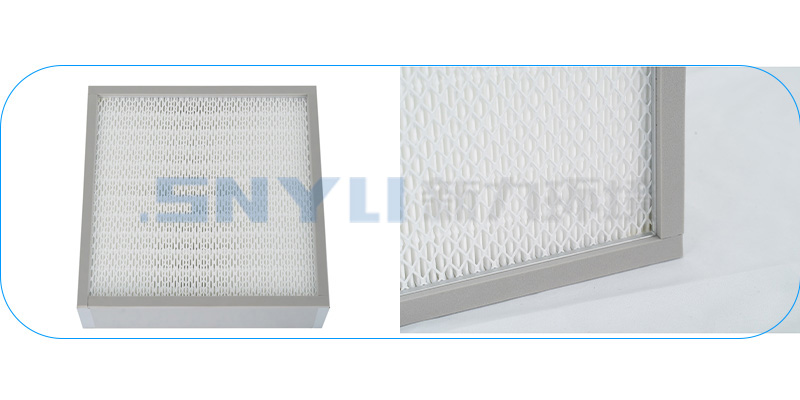

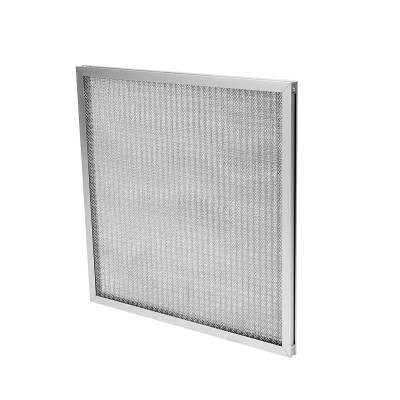

Mini pleat HEPA filter:The HEPA filter is made of ultra-fine glass fiber filter paper, PP filter paper or PTFE filter paper, separated by hot melt adhesive, and the outer frame is made of aluminium alloy profile or galvanized plate, sealed with environmentally friendly polyurethane sealant.

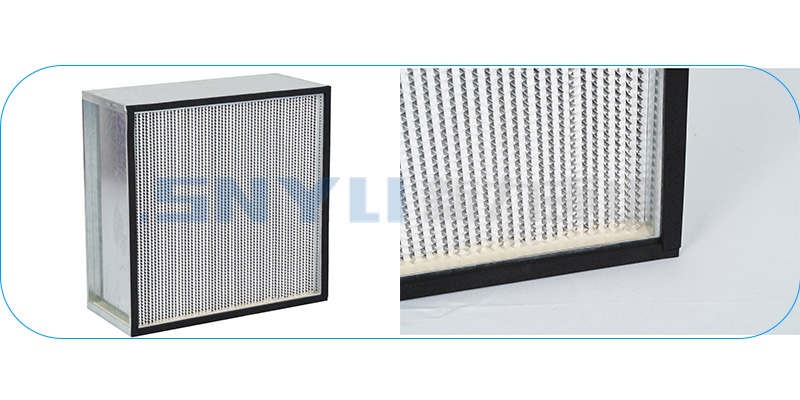

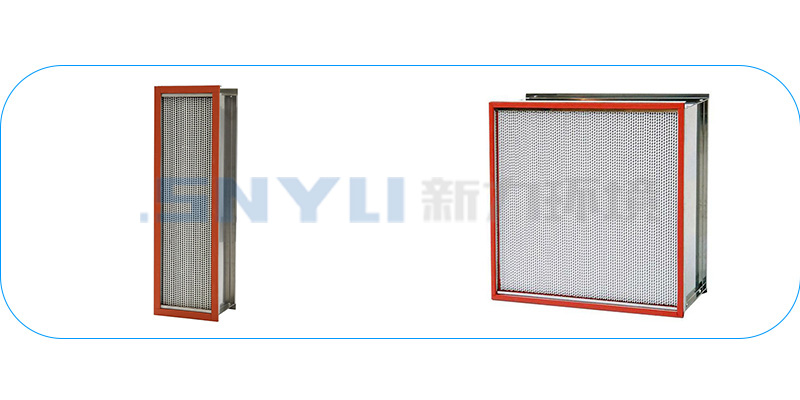

Deep pleat HEPA filter: HEPA filters are made of ultra-fine glass fibre filter paper or polypropylene filter paper, which are tightly folded. The filter paper is spaced by small inserts made of paper or aluminium foil separators to maintain smooth passage, and the outer frame is made of galvanized plate or aluminium alloy profiles, sealed with polyurethane sealant.

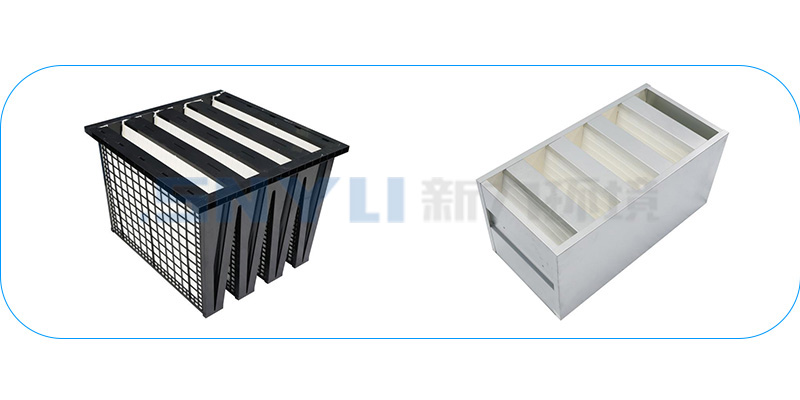

Large airflow filter: large airflow type filter, also known as V bank air filter. It is a common filter for central air-conditioning and centralised ventilation system.

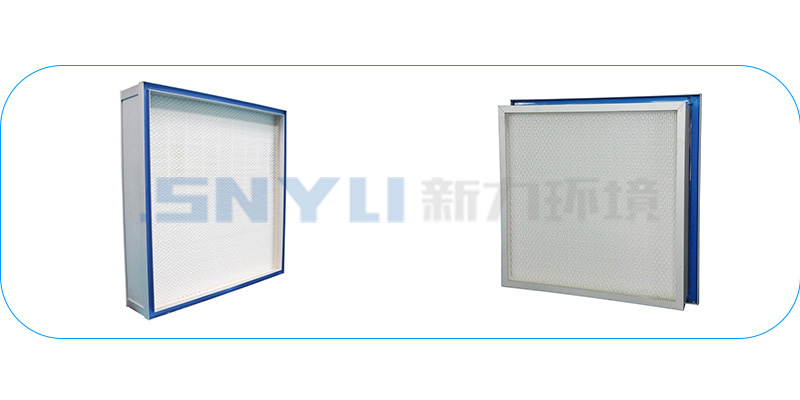

Gel seal HEPA filter: Gel seal is a better method of mechanical compression device commonly used in China at present. Easy to install and reliable sealing, it is a widely used sealing method for HEPA filters.

High temperature resistant filter: High temperature resistant HEPA filters use a separator design, and the corrugated separator can keep the pleat layer spacing at equal distances to maximise the use of the filter media under small resistance.

Standards for HEPA filters

The Chinese national standard ‘High Efficiency Air Filter’ GB/T 13554-2020, which has been implemented since 1 February 2021, defines the performance and classification of high efficiency air filters.

The European standard EN 1822 defines the performance and classification of air filters, including E10 to E12, H13 and H14.

The American air filter standards ASHRAE 52.2 (for Primary~EPA air filters) and IEST-RP (for HEPA~ULPA air filters) classify air filters into 16 classes from MERV1-MERV16.

ISO 14644 is an international standard, mainly used in cleanrooms, which classifies cleanrooms into different classes according to the concentration of particulate matter.

SNYLI specializes in the development and production of air filtration products, with a factory of more than 20,000 square meters, a number of clean production workshops, professional technical team, to provide you with a full range of support. Buy air filter, please contact us!