Introduction:

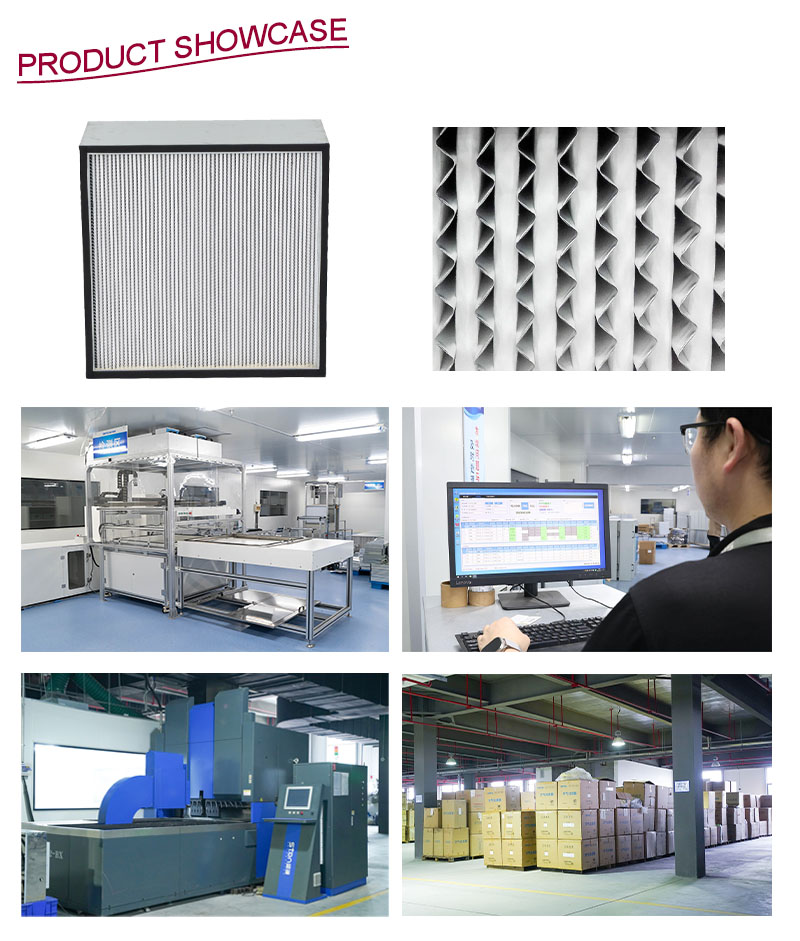

Deep Pleat HEPA filter usually uses high efficiency glass fibre filtration media, which can effectively filter fine particles, dust, bacteria, viruses and other pollutants in the air and provide a clean air environment.

This type of air filter is usually used in environments with high air quality requirements, such as operating theatres, laboratories, medical facilities, pharmaceutical plants and other places. They can effectively purify the air, safeguard the safety and health of staff and equipment, and prevent airborne contaminants from affecting humans and products.

![HVAC Deep Pleat HEPA Filter HVAC Deep Pleat HEPA Filter]()

| Housing | Usually made of metal, it is used to hold the filter media and provide protection and support. |

|---|

| Filter Media | The core of a deep pleat HEPA filter. The filter media is usually made of high efficiency glass fibre material. |

|---|

| Separators | Usually paper or aluminium foil, they are used to separate the filter media to ensure even distribution of air flow through the entire filter and to improve filtration efficiency. |

|---|

| Gaskets | Sealing strips installed on the edges of the filter to ensure air tightness. |

|---|

| Std. EN1822:2009 | E10 / E12 / H13 / H14 |

|---|

| Efficiency | 95% 99.97%,99.99%,99.999% @0.3μm (DOP/PSL/PAO Counting method) |

|---|

| Maximum temperature | 70℃ |

|---|

| Maximum relative humidity: | 100% |

|---|

| Customized size | Available |

|---|

Different structures:

Single header type | Double header type | Box type |

![Single header type deep pleat HEPA filter Single header type deep pleat HEPA filter]() | ![Double header type deep pleat HEPA filter Double header type deep pleat HEPA filter]() | ![Box type deep pleat HEPA filter Box type deep pleat HEPA filter]() |

Common dimensions:

Size (mm) | Rated air flow(m3/h) | Recommended air flow | Initial pressure drop (Pa) | Final Pressure Drop (Pa) | Efficiency(%) |

|---|

305×305×150 | 500 | 500 | ≤120Pa | ≤400Pa | 99.999 |

484×484×150 | 700 | 700 | ≤120Pa | ≤400Pa | 99.999 |

610×610×150 | 1000 | 1000 | ≤120Pa | ≤400Pa | 99.999 |

915×610×150 | 1500 | 1500 | ≤120Pa | ≤400Pa | 99.999 |

610×610×292 | 2000 | 2000 | ≤120Pa | ≤400Pa | 99.999 |

915×610×292 | 3000 | 3000 | ≤120Pa | ≤400Pa | 99.999 |

Performance Features:

1. High efficiency filtration: The deep pleat HEPA filter adopts a deep pleat design, which increases the filtration area, improves the filtration efficiency, and can effectively capture the tiny particles and pollutants in the air.

2. Low resistance: The deep pleated design can ensure high efficiency filtration while reducing the resistance of air flow and reducing system energy consumption.

3. Long service life: The solid structure and uniform support of filter media can maintain long-term stable filtration performance and prolong service life.

4. High capture rate: It can effectively capture dust, bacteria, viruses and other particulate pollutants in the air to ensure air quality and environmental cleanliness.

5. Good stability: Reasonable design and solid structure, able to maintain stable filtration effect in various working environments, which is helpful to maintain air quality.

6. Widely used: Suitable models and specifications can be selected according to different needs, applicable to various air purification systems, air-conditioning systems and air filtration projects in clean environments.

7. Efficient purification: It can effectively purify harmful substances in the air and provide a clean and healthy air environment, and is suitable for places with high requirements for air quality, such as medical institutions, laboratories, electronic factories, and so on.

Applications:

1. Medical field: hospital operating rooms, laboratories and other places that require high cleanliness air.

2. Pharmaceutical industry: pharmaceutical manufacturing, packaging and other production environments with high air quality requirements.

3. Electronic industry: electronic product assembly line, semiconductor manufacturing and other areas that require strict air cleanliness.

4. Food processing: food production workshops, packaging areas and other places that need to maintain air hygiene.

5. Industrial production: industrial production environments with strict requirements for dust and particles.

![SNYLI Deep Pleat HEPA Filter Applications SNYLI Deep Pleat HEPA Filter Applications]()

About us:

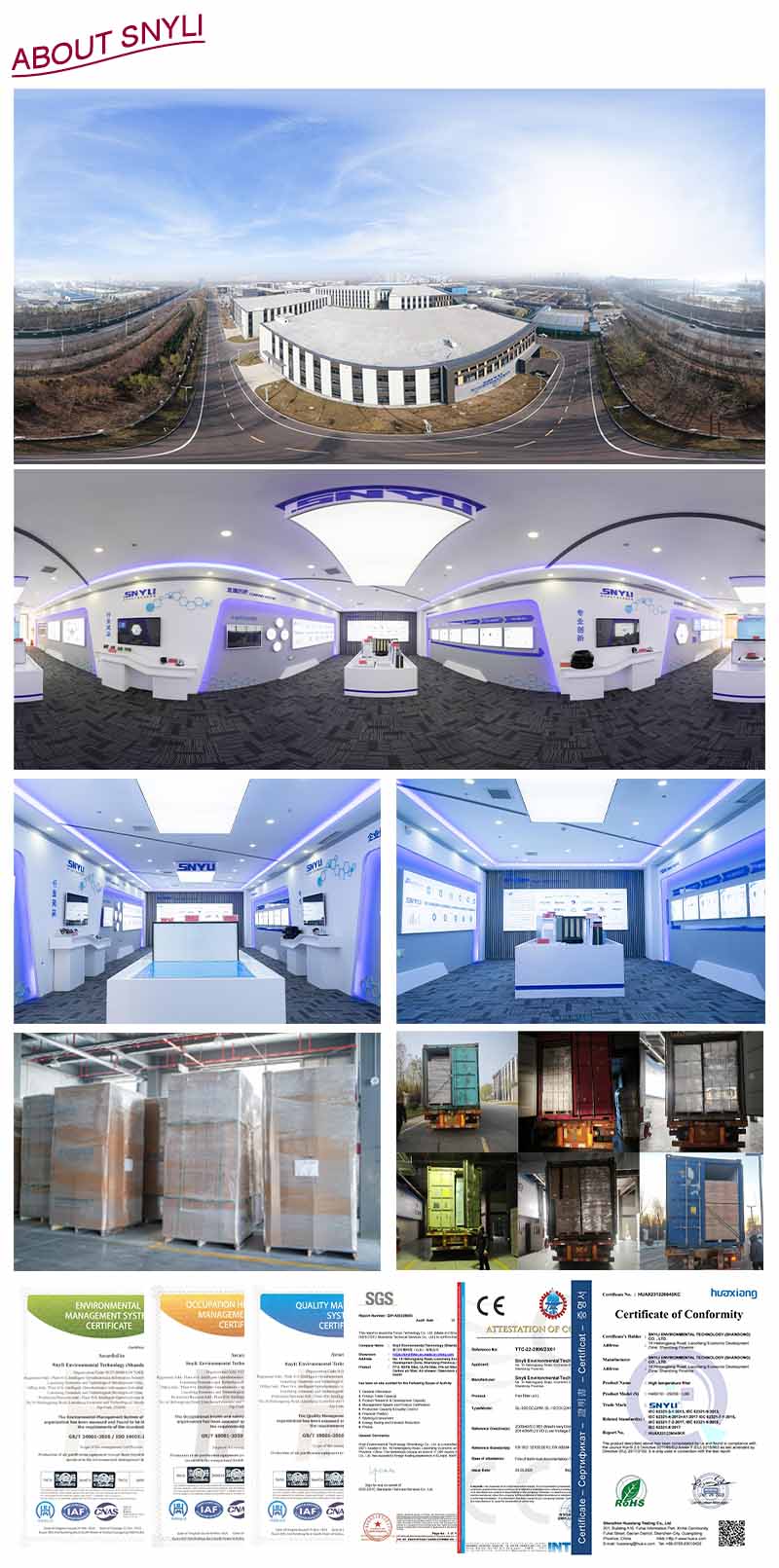

Snyli Environmental Technology (Shandong) Co.,Ltd has always insisted on putting customers' interests in the first place, since its establishment, SNYLI has gone through more than ten springs and autumns, and successfully established long-term co-operation with hundreds of domestic and foreign enterprises. In addition, SNYLI always adheres to the principle of advancing with the times, and has already obtained a number of R&D patents, and has been cooperating closely with industry associations, university research institutes, and third-party laboratories for a long time.

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()