Introduction:

The 350 ℃ high temp air filter is a kind of air filter specially used in high temperature environment. It has high-temperature resistant performance and can normally operate continuously at temperatures up to 350 degrees to filter impurities and particles in the air.

![High Temp Air Filter High Temp Air Filter]()

All materials of the high temperature resistant air filter are composed of temperature resistant materials. Generally speaking, in order to ensure the normal performance of the filter, the outer frame will be made of stainless steel material, while the filter media is usually well-chosen fiberglass material. The overall structure is deep pleated, and the frame and filter media are assembled with high temperature resistant silicone or ceramic adhesive.

This kind of deep pleated design enables the filter to increase the filtration area to a certain extent, allowing the air to more fully come into contact with the filter media and improving the filtration effect. In addition, it prevents the filter media from shifting and extends the service life of the filter.

| Frame material | Stainless Steel |

|---|

| Filter media material | Ultra fine glass fiber filter paper |

|---|

| Sealant | Silicone/Ceramic adhesive |

|---|

| Gasket | Glass fiber sealing strip |

|---|

| Divider | Aluminum foil |

|---|

| Optional thickness | 80,96,120,150,220,292,305 |

|---|

| Operating temperature | 350℃ |

|---|

| Max. Humidity | ≦ 100% RH |

|---|

This type of filter is usually used in industrial environments with strict requirements, such as steel, glass manufacturing and other fields, to ensure that the air quality meets the requirements and protects the normal operation of equipment.

![High Temp Air Filter High Temp Air Filter]()

Common dimensions:

Dimensions (mm) | Rated Airflow(m³/h) / Initial Resistance(Pa) | Filtration Area (㎡) | Efficiency Grade |

305*610*150 | 500/190 | 4.7 | H13 |

610*610*150 | 1000/190 | 9.59 |

610*1220*292 | 4450/190 | 42.5 |

610*915*150 | 1500/190 | 0.75 |

610*610*292 | 2200/190 | 21.25 |

610*1220*150 | 2000/220 | 19.17 | H14 |

610*610*292 | 2200/220 | 21.25 |

305*610*292 | 1100/220 | 10.52 |

610*1220*292 | 4450/220 | 42.5 |

Performance characteristics:

1. High temperature resistance performance: It has excellent high temperature resistance, able to work normally in high temperature environments up to 350 ℃, keeping the filtration effect unaffected.

2. High-efficiency filtration: High temp air filter adopts specially designed high-temperature-resistant glass fiber filter media, which can efficiently capture fine particles and impurities in the air and ensure the cleanliness of the outlet air.

3. Long service life and stability: As all materials are made of high temperature resistant materials, this filter has a long service life and stability, is not easily damaged by high temperature, and is capable of continuous and stable filtration operation.

4. Low resistance design: Reasonable design and scientific structure can reduce the airflow resistance of the filter, ensure smooth air flow and reduce energy consumption.

5. Easy to install and maintain: Simple structure, easy to install, easy to maintain and clean, saving labor and time costs.

6. Environmental protection and health: Good filtration effect, able to reduce particles and harmful substances in the air, improve air quality, protect the environment and personnel health.

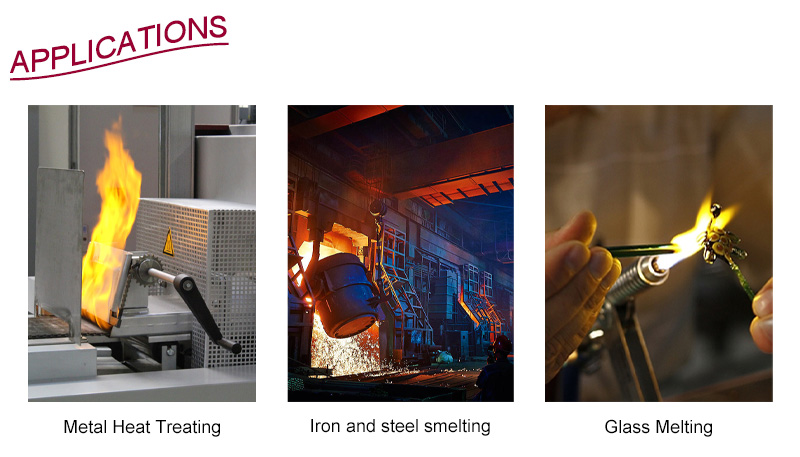

Application places:

1. Iron and steel industry: High temp air filter is used for air filtration in high temperature production process such as steel making and iron making, to protect production equipment and environment.

2. Glass manufacturing industry: High temp air filter is suitable for air filtration in the process of glass melting and molding to ensure the cleanliness and stability of the production process.

3. Ceramic industry: High temperature filter is used for high-temperature atmosphere purification and filtration treatment in ceramic production to ensure product quality.

4. Automobile manufacturing industry: High temperature air filter is used to filter exhaust gas and purify air in high-temperature environments such as automobile painting workshop to protect workers' health and the environment.

5. Electric power industry: It is used for air purification and filtration in high-temperature environments such as power stations and power plants to protect the stable operation of equipment.

6. Petrochemical industry: It is used for gas treatment and emission control in high temperature environments such as oil refineries, chemical plants, etc., to maintain the safety of production equipment and the environment.

7. Food processing industry: It is used for air purification and bacterial filtration in high-temperature food processing lines to ensure product quality and food safety.

8. Building materials industry: It is used for air treatment and purification in the process of cement production, brick and tile combustion, etc., to maintain the normal operation of equipment.

![Applications of High Temp Air Filter Applications of High Temp Air Filter]()

About us:

Snyli Environmental Technology (Shandong) Co., Ltd has more than ten years of experience in R&D and production, with strong strength.

With more than 20,000 square metres of production base, the annual production capacity is in millions. Automated clean production workshop, independent warehouse, guaranteed delivery. With professional technical team, more than ten years of industry experience, in-depth application expansion.

Strictly in accordance with ISO9001:2015 quality system standards, the introduction of advanced dust particle counters and other inspection and processing equipment to ensure product quality, qualified before being allowed to leave the factory.

Professional sales staff to match the demand, after-sales timely follow-up of customer use. Any problems encountered during the use of the product can be put forward to us at any time. Regular tracking of customers, so that customers get a good purchasing experience.

![Snyli Environmental Technology (Shandong) Co., Ltd Snyli Environmental Technology (Shandong) Co., Ltd]()