Introduction:

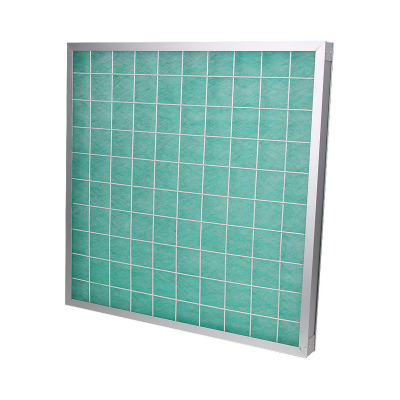

High temperature air filter is a device designed to filter air in high temperature environments, usually used in industrial production environments where high temperature gases need to be handled. These filters are usually designed with high temperature resistant materials and construction to ensure that their filtration performance and safety are maintained under high temperature conditions.

| Frame | Stainless Steel |

|---|

| Header | Box type, Single/ Double header |

|---|

| Media | High temp resistance Glass fiber |

|---|

| Separator | Aluminum foil |

|---|

| Sealant | Ceramic adhesive |

|---|

| Max operating Temperature | ≦ 450°C |

|---|

![High Temperature Air Filter High Temperature Air Filter]()

Common dimensions:

Dimensions | Media Area (㎡) | Rated Air Flow (m³/h) | Initial Pressure Drop (Pa) |

W×H×D (mm) | Standard | High Capacity | Standard | High Capacity | H12 | H13 | H14 |

320×320×220 | 4.1 | 6.1 | 350 | 525 | ≤200 | ≤235 | ≤255 |

484×484×220 | 9.6 | 14.4 | 1000 | 1500 |

726×484×220 | 14.6 | 21.9 | 1500 | 2250 |

968×484×220 | 19.5 | 29.2 | 2000 | 3000 |

315×630×220 | 8.1 | 12.1 | 750 | 1200 |

630×630×220 | 16.5 | 24.7 | 1500 | 2250 |

945×630×220 | 24.9 | 37.3 | 2200 | 3300 |

1260×630×220 | 33.4 | 50.1 | 3000 | 4500 |

305×305×150 | 2.4 | 3.6 | 250 | 375 |

305×610×150 | 5.0 | 7.5 | 500 | 750 |

610×610×150 | 10.2 | 15.3 | 1000 | 1500 |

915×610×150 | 15.4 | 23.1 | 1500 | 2250 |

1220×610×150 | 20.6 | 30.9 | 2000 | 3000 |

305×610×292 | 10.1 | 15.1 | 1000 | 1500 |

610×610×292 | 20.9 | 31.3 | 2000 | 3000 |

Performance strengths:

1.Efficient filtration performance: the use of high-quality glass fiber filter media and specially designed structure can effectively filter particles, pollutants and particulates in the air and safeguard air quality.

2. Long service life: the high temperature resistant air filter is reasonably designed and made of durable materials, which can be used stably for a long time, reducing the number of replacements and saving maintenance costs.

3. Low resistance and high airflow: with good pneumatic performance, it will not produce excessive resistance to the system and keep the air flow unimpeded.

4. High reliability: with strict quality control and test verification, the high-temperature resistant air filter has high reliability and stability, and can operate stably and trouble-free for a long time.

5. Environmental protection and energy saving: the filter can effectively purify the air, which not only protects the equipment and the working environment, but also contributes to energy saving and emission reduction, and meets the requirements of modern environmental protection.

Application places:

High temperature air filter is mainly used in industrial production fields that produce high temperature gases and particles to ensure a clean and safe environment in the production process and to meet environmental regulations and requirements.

1. Iron and steel industry: high-temperature gases and soot are generated in the process of iron and steel production, and high-temperature resistant air filters are used to filter and purify these industrial exhaust gases and reduce the pollution of the environment.

2. High-temperature furnace and kiln industry: such as glass, ceramics, cement and other industries, the high-temperature exhaust gases and particles generated in the furnace and kiln need to be processed through the filter to ensure the environment and product quality.

3. Metallurgical industry: the high temperature gases and soot generated in the processes of metallurgical ironmaking and steelmaking need to be purified and discharged through high temperature resistant air filters to meet the requirements of environmental protection.

4. Heat treatment industry: the heat treatment process needs to control the temperature and atmosphere, and the high-temperature resistant air filter can be used to filter the waste gas and particles generated in the heat treatment process.

5. Petrochemical industry: oil refining, chemical industry and other industries need to deal with high-temperature exhaust gases and harmful gases, and high temperature air filters can effectively purify these gases to protect the environment and safety.

6. High-temperature flue gas treatment: in dust removal, desulfurization and other industrial emission gas treatment systems, high temperature resistant air filters are widely used to purify high-temperature gases.

![Applications Applications]()

SNYLI Production workshop:

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.

![SNYLI Production Workshop SNYLI Production Workshop]()

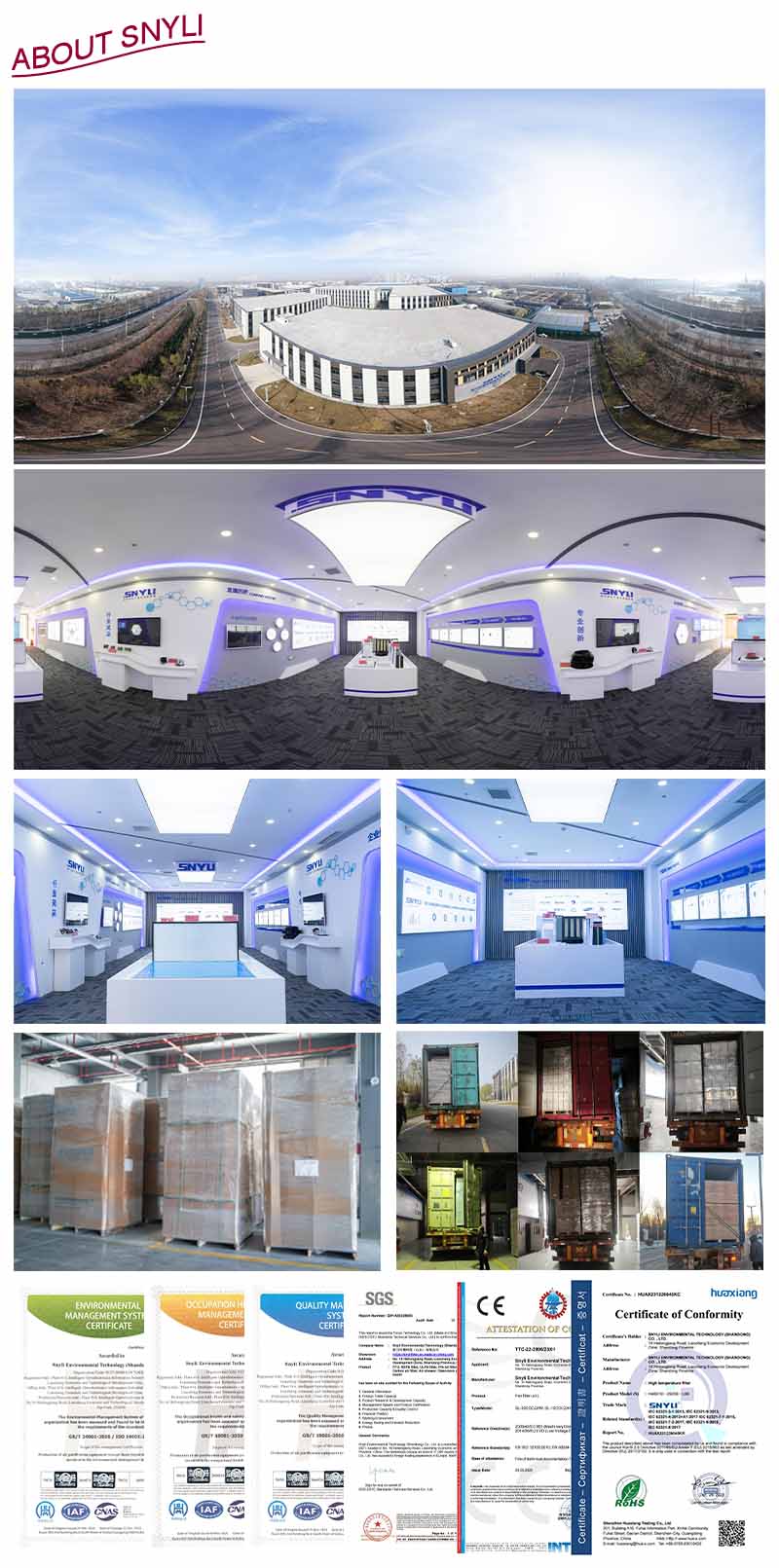

About us:

Snyli Environmental Technology (Shandong) Co., Ltd has the strength and experience in R&D and production to provide a wide range of air filtration products to our customers. Since SNYLI has been engaged in foreign trade export, we have been constantly praised by customers from various countries, and we are always proud of the quality products we have provided to our customers. In the future, we will always keep our original intention, continue to develop and innovate, and provide even better products and services to customers from all over the world.

With more than 20,000 square metres of production base, the annual production capacity is in millions. Automated clean production workshop, independent warehouse, guaranteed delivery. With professional technical team, more than ten years of industry experience, in-depth application expansion.

Strictly in accordance with ISO9001:2015 quality system standards, the introduction of advanced dust particle counters and other inspection and processing equipment to ensure product quality, qualified before being allowed to leave the factory.

Professional sales staff to match the demand, after-sales timely follow-up of customer use. Any problems encountered during the use of the product can be put forward to us at any time. Regular tracking of customers, so that customers get a good purchasing experience.

![Snyli Environmental Technology (Shandong) Co., Ltd Snyli Environmental Technology (Shandong) Co., Ltd]()