Key Applications of Bag Filters in the Pharmaceutical Industry

In the pharmaceutical industry, every cubic meter of air is directly related to the quality, safety and compliance of drugs.

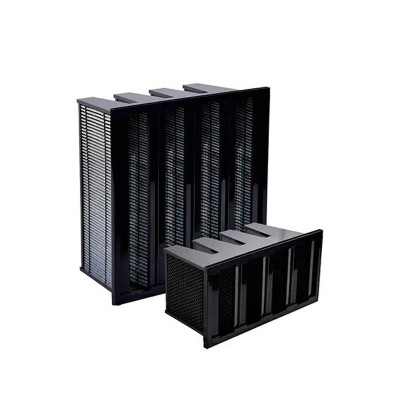

Clean room environment is the lifeline of drug production, any small dust, microorganisms may cause contamination of the product, bringing inestimable risk. In this strict system, bag filters, as the backbone of the central air conditioning purification system, have built a solid and reliable barrier for pharmaceutical enterprises with their outstanding performance.

I. Why are bag filters the ideal choice for the pharmaceutical industry?

The requirements for air filtration equipment in the pharmaceutical industry far exceed those in the ordinary commercial field. It not only demands high efficiency but also emphasizes stability, reliability and compliance. The design features of the bag filter perfectly meet these requirements:

High dust holding capacity and long service life: The production of pharmaceuticals, especially solid dosage forms, generates a large amount of dust. The huge filtration area of the bag filter enables it to have an extremely high dust holding capacity, allowing it to operate stably for a long time without clogging. This not only reduces the downtime caused by frequent filter bag replacement, but also lowers the risk of contamination introduced due to replacement operations, ensuring the continuity of production.

Outstanding filtration efficiency: The pharmaceutical industry typically adopts a three-stage filtration mode of primary, medium and high efficiency. As the core medium-efficiency filter, the bag filter can effectively capture particles ranging from 1 to 5 microns (including some microbial carriers), significantly reducing the load on the subsequent high-efficiency filter (HEPA).

Low resistance and energy-saving features: GMP cleanrooms require 7x24-hour continuous air supply, which consumes a huge amount of energy. Bag filters have a relatively low initial resistance due to their large filtration area and can maintain a stable pressure difference for a long time, significantly reducing the energy consumption of fans and saving a large amount of operating costs for enterprises.

Stable structure, safe and reliable: The built-in metal support frame ensures that the filter bags do not deform or break under high-speed airflow, preventing secondary pollution caused by filter material damage, and meeting the ultimate requirements of the pharmaceutical industry for equipment reliability.

II. Specific application Scenarios of Bag Filters in Pharmaceutical production environments

Bag filters are widely used in various key areas of the pharmaceutical industry:

HVAC system for clean areas: It is the standard configuration of the medium-efficiency filter section in the air conditioning and purification system of GMP clean areas (such as D-class and C-class areas), providing clean air that meets the grade requirements for the core area.

Process dust removal: In processes with high dust generation such as tablet pressing, capsule filling, and powder mixing, bag filters can be used as terminal filters for process dust removal equipment.

Protecting the key equipment at the back end: As a pre-filter for high-efficiency filters (HEPA) and fan filter units (FFUs), bag filters intercept the majority of particulate matter, significantly extending the service life of these more expensive and critical devices and reducing the overall cost.

III. Key Considerations for Selecting and Using Bag Filters

When applying bag filters in the pharmaceutical industry, the following points should be particularly noted:

Compliance and materials: The filter material itself should comply with relevant medical standards, not fall off, and be free of volatile substances to avoid becoming a new source of pollution. The outer frame material should be corrosion-resistant and easy to clean.

Efficiency grade matching: It is necessary to scientifically select the corresponding efficiency grade (such as F7/F8/F9) of bag filters based on the grade requirements of the clean room, the efficiency of the front-end primary filter, and the demand for the back-end HEPA filter.

Professional installation and maintenance: Installation must be carried out by professionals in accordance with standard operating procedures to ensure good sealing. And establish a strict differential pressure monitoring and regular replacement system, and form a complete traceability record to meet the GMP audit requirements.

Although bag filters are not the most dazzling stars in pharmaceutical equipment, they are the silent guardians of a clean environment.

With its economic, efficient and stable characteristics, it plays an irreplaceable role in ensuring drug safety, improving production efficiency and controlling operating costs.

Selecting the appropriate bag filter and implementing scientific management is an important part of every pharmaceutical enterprise's construction of a high-quality management system.

Contact us to customize your exclusive solution!