The Role of HEPA Filters in Gas Turbine Inlet Air Filtration Systems

HEPA filters play a crucial "guardian" role in the gas turbine filtration system. Its core function is to efficiently capture particulate pollutants in the air (such as dust, salt, smoke, etc.) and prevent them from entering core components like compressors and turbines.

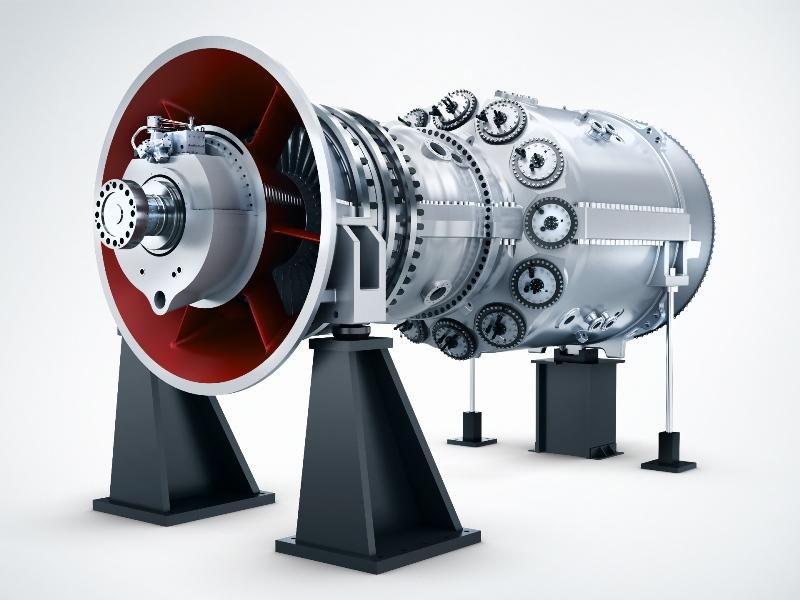

Gas turbines, as core power equipment in fields such as power, aviation, and energy, their operational status directly affects the safety and economy of the entire system. Just as humans need clean air to breathe healthily, the high-speed and precise impellers of gas turbines also have extremely strict requirements for the quality of the intake air. Against this backdrop, high-efficiency filters are by no means simple auxiliary components; rather, they are the indispensable first and most crucial life barrier to ensure the "healthy, long life and efficient operation" of gas turbines.

I. Core Function: From Protection to Efficiency Enhancement

The main mission of HEPA filters is to efficiently remove particulate contaminants from the intake air. These pollutants include dust, sand particles, pollen, salt crystals, industrial emissions and aerosols such as cooking fumes. Its functions are specifically reflected in the following aspects:

Prevent corrosion and wear, and extend the lifespan of core components: The compressor and turbine blades of a gas turbine rotate at extremely high speeds. Their precise design and expensive coatings are highly sensitive to the impact of tiny particles. Unfiltered hard particles will continuously strike and wear the blade surface like a sandstorm, while corrosive substances such as salts in the air will accelerate the stress corrosion and sulfidation of the blade metal under high-temperature and high-pressure conditions. High efficiency filters can effectively intercept these harmful substances, fundamentally protecting core components worth millions, greatly extending the overhaul cycle and service life, and significantly reducing the total life cycle cost.

Maintaining operational efficiency and output power: The accumulation (scaling) of contaminants on the blade surface can alter the aerodynamic shape of the blade, disrupt the precise airflow channels, and lead to a decrease in compressor efficiency and pressure ratio. To maintain the same output power, the unit must consume more fuel, resulting in an increase in operating costs. In more severe cases, scaling can cause compressor surge, forcing the unit to shut down for cleaning. The high-efficiency filter can keep the flow path unobstructed for a long time by providing clean air intake, ensuring that the unit always operates near the designed high-efficiency point and guaranteeing the stability and economy of the output.

Enhancing operational reliability and availability: Unplanned downtime is the most costly loss in the operation of gas turbine power stations. Frequent cleaning, component replacement or shutdowns caused by intake air pollution can seriously affect the reliability and availability of power plants. HEPA filters, as a reliable pre-barrier, significantly reduce the risk of unexpected shutdowns caused by particulate matter issues, providing a solid foundation for stable power supply and safe production in power plants.

In conclusion, HEPA filters directly safeguard the expensive heart of the unit by providing continuous and clean intake air, and they are the cornerstone for achieving the three core goals of long service life, high efficiency, and high reliability of gas turbines. The savings in maintenance costs, improvements in fuel efficiency and reductions in downtime brought about by investment in high-performance filtration systems will eventually translate into significant economic benefits and competitive advantages. Therefore, in the design and selection of any gas turbine filtration system, the importance of high-efficiency filters must be given top priority for consideration.

II. SNYLI- A professional manufacturer of HEPA filter

We are well aware of the significance of clean intake to the gas turbine, the "heart of industry". We can not only offer you a product, but also provide you with all-round value protection throughout the entire life cycle of your gas turbine filtration system.

| V bank filter | Mini pleat HEPA filter |

Outstanding core product power: We use high-performance ultra-fine glass fiber or synthetic fiber filter materials, which can efficiently capture sub-micron particles, salts and oil mist aerosols, effectively protecting your compressor and turbine blades from corrosion and wear. This is the cornerstone for ensuring the output and efficiency of the unit.

Tailor-made system solutions: We reject a "one-size-fits-all" approach. We will tailor the filtration grade configuration (such as F7→H13 combination) and product selection for you based on your specific model, local environment (coastal high salt, desert high dust, urban industrial pollution) and operating conditions, to achieve the best balance between filtration efficiency and operating resistance, maximize the service life of the filter element and reduce energy consumption.

Outstanding long-term economy: Every filter we produce is dedicated to reducing your total cost of ownership (TCO). With excellent dust-holding capacity and a longer replacement cycle, we help you significantly reduce spare parts consumption, downtime for replacement, and additional fuel costs due to high pressure differences. Invest in quality and enjoy long-term benefits.

Continuous technical support and service: We are not only a supplier but also your technical partner. We offer professional intake system diagnosis, post-filter air quality analysis and preventive maintenance suggestions to help you optimize system operation, avoid risks and ensure that your gas turbine always receives the most reliable protection.

In conclusion, what we deliver is not merely a filter, but a reliable guarantee for the safety, efficiency and long-term stable operation of the unit. Choosing us means choosing a dedicated and trustworthy guardian for your core assets.

Contact us for your exclusive solution!