Introduction:

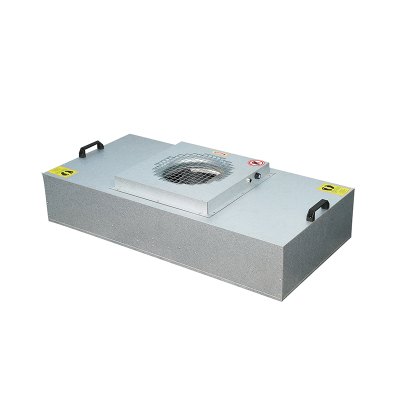

Clean booth is a kind of air purification equipment with local high clean environment, applicable to the workplace which needs specific clean environment. Its main components include box, fan, primary air filter, damping layer, lamps and other components, the housing is generally made of plastic spraying process. This kind of equipment can be hanging installation or placed on the ground to support, compact structure, easy to use.

The clean booth can be used individually or connected together through multiple units to form a banded clean area. Through a high efficiency air filtration and circulation system, the clean booth can effectively remove airborne particles and hazardous substances, providing a relatively cleaner working environment and helping to safeguard the cleanliness of the workplace and the health of staff.

| Frame material | 50x50 aluminum extrusions/Stainless steel square tube/Power coated steel sheets square tube |

|---|

| Flange cover material | Standard rolled steel plate |

|---|

| Outer wall material | Tempered glass/Anti-static curtain |

|---|

| Fan filter unit | Adopt DC sensorless brushless dc motor,energy saving,low noise,stable performance. |

|---|

| Customized size | Available |

|---|

![Clean booth Clean booth]()

Overall, the clean work booth is a powerful and flexible air purification equipment that can meet the cleanliness needs of different workplaces and improve work efficiency and the quality of the work environment.

Common dimensions:

Area(㎡) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 300 | 500 | 1000 | 2000 |

Clean grade FS209E | FFU Qty (Pcs) |

Class 100 | 12 | 24 | 36 | 48 | 60 | 72 | 84 | 96 | 108 | 120 | 360 | 600 | 1200 | 2400 |

Class 1000 | 4 | 8 | 12 | 16 | 20 | 24 | 28 | 32 | 36 | 40 | 120 | 200 | 400 | 800 |

Class 10000 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 60 | 100 | 200 | 400 |

Performance features:

1. High-efficiency air filtration: The clean booth is equipped with air filters that can effectively filter airborne particles and harmful substances to provide a clean workspace.

2. Air circulation system: Effective air circulation system keeps the air circulating, effectively cleans the air and reduces pollution.

3. Lamps for Lighting: Lamps provide good lighting conditions to facilitate the work of the staff.

4. Compact structure: Compact structure, small footprint, suitable for use in limited space.

5. Flexible installation: Clean booths can be hung or placed on the ground for support, easy to install and operate.

6. Multi-functional application: Clean booths can be used individually or connected together through multiple units to form a continuous clean area to meet different cleanliness requirements of the workplace.

7. Enhancement of work efficiency: Provide local high clean environment clean booths help to reduce the impact of external interference and pollutants on the work, enhance work efficiency.

Areas of application:

Clean booth is a space specially designed to maintain a clean environment and is mainly used in the following application areas:

1.Medical industry: used in operating theatres, clean rooms, laboratories and other medical places to ensure aseptic conditions for surgical procedures and experimental operations.

2. Pharmaceutical industry: used in drug production, packaging and other links to ensure the quality and safety of drugs.

3. Electronic industry: used in semiconductor production, microelectronics manufacturing and other fields, to maintain high cleanliness of production equipment and products.

4. Food industry: used in food processing, packaging and other links to ensure food hygiene and safety.

5. Aerospace industry: used in the production of aircraft parts, spacecraft assembly and other links to ensure that the product is not contaminated in the production process.

6. Painting industry: used in automobile painting, furniture painting and other fields, to ensure that the painting operation is free from dust, bacteria and other pollution.

7. Research laboratories: used in chemical laboratories, biological laboratories and other scientific research institutions to ensure the accuracy and reliability of experimental operations.

![Applications Applications]()

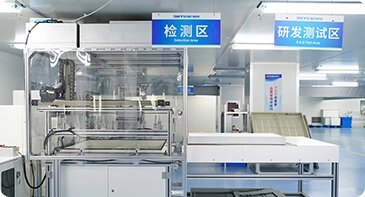

SNYLI Production workshop:

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.

![SNYLI Production workshop SNYLI Production workshop]()

About us:

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, registered in Liaocheng City, Shandong Province, mainly engaged in air filtration products. Since the establishment of our company, we have been continuously deepening our research and development to improve our strength, and now we have mastered many patents and obtained ISO/CE certificates.

After more than ten years, SNYLI has set up branches in many places in China and a trading company in Jinan City, Shandong Province. At present, SNYLI products have been exported to both home and abroad, and we have signed long-term co-operation agreements with customers in many countries.

We always put the interests of customers in the first place, regularly follow up customer feedback, and strive to improve our own strength, and the constant pursuit of progress.

Giving us a chance to co-operate will be a decision that benefits both parties! SNYLI welcomes your enquiry!

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()