The Backbone of Spray Booth Efficiency: Paint Stop Fiberglass Filters

In industrial surface treatment and coating applications, controlling airborne paint overspray is critical for both production quality and environmental compliance. One of the most reliable solutions is the use of paint stop fiberglass filters. These filters are specifically designed to capture paint particles suspended in airflow within spray booths, thereby ensuring cleaner exhaust air and maintaining optimal painting conditions.

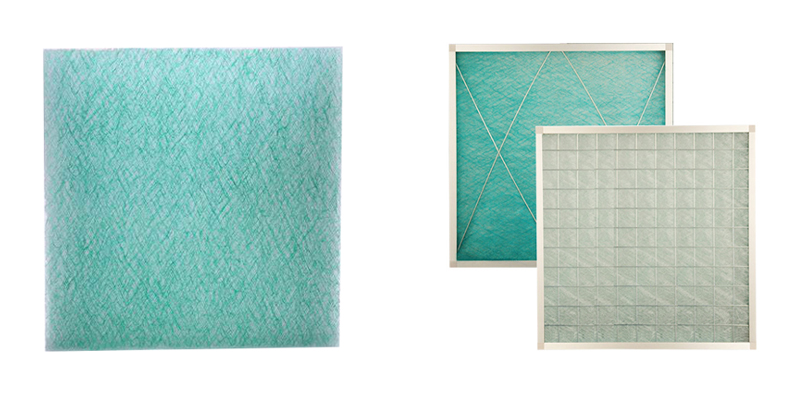

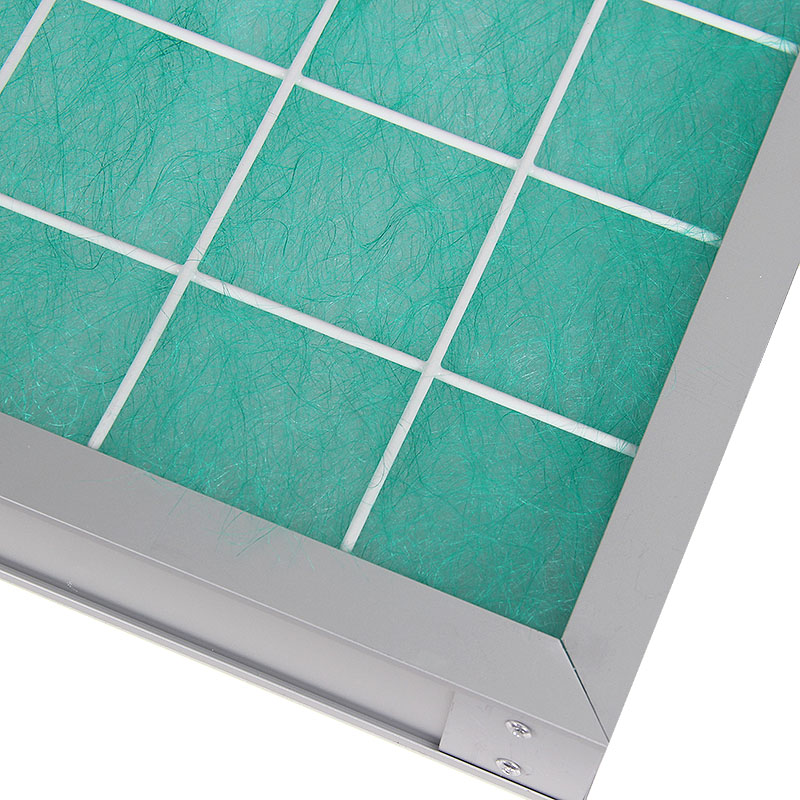

1. Material and Structure

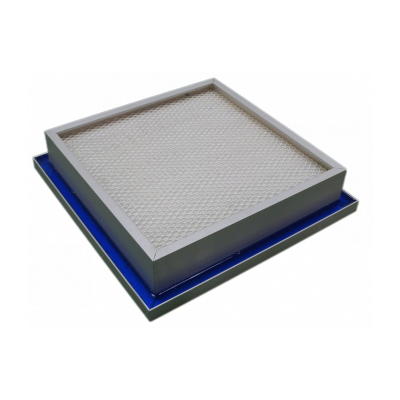

Paint stop fiberglass filters are made from continuous strands of glass fibers, bonded together in a progressively dense, multi-layer structure.

The “progressive density” design means fibers are coarser on the air inlet side and become finer toward the air outlet side. This gradient structure allows the filter to trap larger particles at the surface while finer particles are captured deeper within the media. As a result, the filter achieves high dust holding capacity without excessive pressure drop.

2. Performance Characteristics

Paint stop fiberglass filters are characterized by high arrestance efficiency, typically above 90–95% for common solvent-based and water-based coatings.

According to tests following EN 779, paint stop filters typically maintain an initial pressure drop of 20–40 Pa at rated air velocity (0.25–0.5 m/s), with a recommended final pressure drop around 200 Pa. The high dust holding and paint holding capacity directly reduces maintenance frequency, saving operational costs.

Filter thickness directly affects performance. Standard paint stop fiberglass filters are produced in thicknesses ranging from 50 mm to 100 mm. A 50 mm filter may hold approximately 2–3 kg of paint per square meter before reaching final pressure drop,while a 100 mm filter can hold up to 4–5 kg/m². This strong correlation between thickness and dust holding capacity is critical for heavy industrial painting lines, such as automotive body shops or large equipment coating facilities.

3. Impact on Spray Booth Operation

While the primary function is to capture paint, paint stop fiberglass filters also play an important role in system performance:

1)Airflow Maintenance: Efficient overspray capture prevents paint buildup in ducts and on fans, which can affect airflow and fan performance.

2)Energy Efficiency: By maintaining consistent airflow resistance, filters help reduce additional energy consumption caused by clogged ducts or fans.

3)Equipment Protection: Properly maintained filters reduce the risk of paint deposition on mechanical components, extending their operational lifespan.

4. Core Advantages

Compared with synthetic fibers, paint stop fiberglass filters offer superior temperature resistance (usually can up to 170 °C), non-flammability, and chemical stability. Additionally, fiberglass media maintain consistent efficiency throughout their service life and won't quickly clog or deform.

From a sustainability perspective, paint stop fiberglass filters are disposable and relatively lightweight, reducing waste disposal costs.

5. Main Applications

Paint stop fiberglass filters are used in a wide range of industrial applications:

1)Automotive paint shops——for car bodies, parts, and repair workshops.

2)Industrial coating lines——machinery,furniture,and metal structures.

3) Aerospace and shipyards——large-scale spray applications requiring high paint holding capacity.

4)General spray booths——across many industries to comply with occupational health and environmental regulations.

6. Customization and Market Demand

With the diversification of coatings (water-based, solvent-based, powder, etc.), demand for customized paint stop fiberglass filters has increased. Manufacturers now offer media rolls of different widths (0.75 m, 1.0 m, 1.5 m, 2.0 m) and lengths (20–22 m), as well as pre-cut pads for easy installation. Some suppliers laminate a polyester backing to improve stability and extend service life. The global market, particularly in automotive and furniture sectors, the applications continues to expand due to stricter VOC emission regulations and workplace safety standards.

7. Conclusion

Paint stop fiberglass filters are a critical component in modern spray booth operations. Their progressive density design, high arrestance efficiency, and robust holding capacity make them effective not only for capturing paint overspray but also for maintaining stable airflow, protecting equipment, and reducing operational energy costs. As environmental regulations tighten and production quality demands rise, these filters will continue to be indispensable in industrial finishing processes.

About SNYLI

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, registered in Liaocheng City, Shandong Province, mainly engaged in air filtration products. Since the establishment of our company, we have been continuously deepening our research and development to improve our strength, and now we have mastered many patents and obtained ISO/CE certificates.

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.