Introduction:

Ultra high efficiency filter (ULPA) is an air filtration device with a filtration efficiency of 99.99% or more, capable of capturing particles in the range of 0.1 to 0.3 microns.

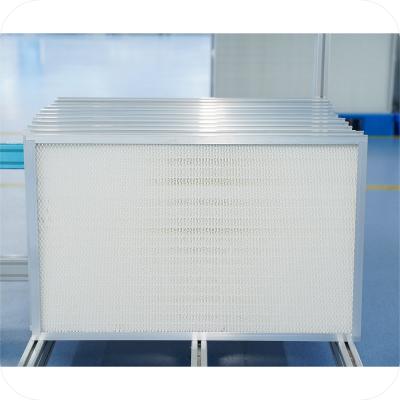

![Fiberglass Mini-Pleat ULPA Air Filter Fiberglass Mini-Pleat ULPA Air Filter]() |

Fiberglass Mini-Pleat ULPA Air Filters are mainly available in U15, U16 and U17 filtration grades, of which the most commonly used is the U15 grade air filter, which is mainly used in clean rooms, laboratories, medical equipment and other places that require high-level purified environments. U15 (EN 1822)/MERV 20 (ASHRAE 52.2) MPPS: ≥99.9995% / DOP: ≥99.9999%@0.12 μm |

Main structural parameters:

Frame: anodised aluminium profile

Style: box type, single flange side, double flange side

Filter media: ultra-fine glass fibre

Separator: hot melt adhesive

Seal: EPDM

Maximum temperature: ≤70℃

Maximum humidity: ≤100% RH

ULPA air filter filter media requirements:

The core competitiveness of Fiberglass Mini-Pleat ULPA Air Filters lies in their filter materials. The ideal filter material should have the following characteristics:

![Fiberglass filter media Fiberglass filter media]() | ![Fiberglass Mini-Pleat ULPA Air Filter Fiberglass Mini-Pleat ULPA Air Filter]() |

Uniform fiber distribution: It is conducive to improving the filtration efficiency and dust holding capacity.

Low resistance: reduce energy consumption and prolong the service life of the equipment.

High strength: ensure the service life and stability of the filter.

High temperature resistance: Some special process high-temperature air supply systems (such as pharmaceutical, medical, chemical and other industries) have high requirements for filter materials, and ultra-high efficiency filters need to have good high temperature resistance.

Chemical stability: The filter material used in the ultra-high efficiency filter should have good chemical stability to prevent chemical reactions in high temperature, high pressure and other environments, which will affect the filtration effect.

Environmental performance: The filter material should meet the requirements of environmental protection and not produce secondary pollution.

The filter material used by SNYLI is high quality ultra-fine glass fibre material, non-combustible in case of fire, high temperature resistant, low resistance, environmentally friendly and non-polluting, which perfectly meets the above requirements.

Applications:

With the development of modern industry and the accelerated process of urbanisation, air quality issues are increasingly attracting people's attention. As a kind of air purification equipment, Fiberglass Mini-Pleat ULPA Air Filters, with their excellent filtration performance, have become a powerful tool for safeguarding air quality in many industrial fields.

Optical electronics, LCD liquid crystal manufacturing: purify workshop air to ensure product quality.

Biomedicine, precision instruments: to ensure the cleanliness of the experimental environment and equipment.

Beverage and food: Ensure the hygiene of the production environment and improve product quality.

PCB printing: purify workshop air and reduce pollutant emissions.

Nuclear power station exhaust, chip factory and other high-end clean rooms: occasions with extremely high requirements for air quality.

As a kind of air purification equipment, ULPA air filters have strict requirements for filter materials. In many industrial fields, ultra-high efficiency filters play a vital role in guarding air quality and promoting green and sustainable development.