Chemical Filtration Principle

Chemical filters selectively adsorb harmful air molecules, rather than mechanically removing impurities as normal filters do.

Chemical filters remove airborne gaseous contaminants. In the field of ventilation and air conditioning, chemical filters use activated carbon as the main filter material. Typical applications of chemical filters are: chip factories, nuclear industry, airports, museums, etc. Chemical filtration materials are also used in some home appliances.

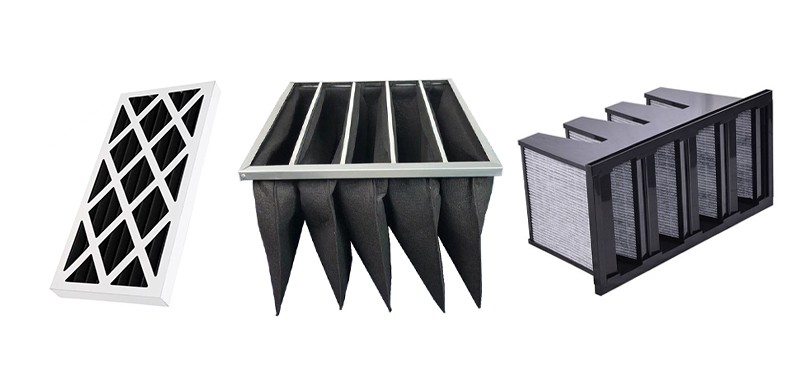

The main styles of activated carbon air filters available from SNYLI are plate, bag, and V-type. Customisation is accepted and samples are available.

The activated carbon material has a large number of microscopic pores that are invisible to the naked eye. In an activated carbon particle of the size of a grain of rice, the internal surface area of the microscopic pores is equivalent to the size of the inner wall of a large living room.

Activated carbon adsorption is classified as "physical adsorption" or "chemical adsorption" depending on the treatment method of the material.

It is customary to refer to adsorption with no apparent chemical reaction as physisorption, which relies mainly on van der Waals forces. After the free molecules with high boiling point in the air come into contact with the activated carbon, some of them coalesce into liquid in the micropores and stay there due to the capillary principle, and some of them fill up the micropores with the same size as the molecules and become one with the material.

Activated carbon has a catalytic effect and can degrade or change certain gaseous pollutants into harmless gases. In addition, activated carbon adsorbs certain airborne microorganisms and kills them. In principle, all porous substances are adsorbent materials, and activated carbon is not the only one, but those substances adsorbed by activated carbon are exactly the same harmful gases that the air-conditioning sector has to deal with.

Physical adsorption is difficult to effectively remove all chemical contaminants, and on some occasions, people chemically treat activated carbon materials to enhance their ability to remove specific contaminants.Adsorption by chemical treatment that results in a chemical reaction between the material and the hazardous air is called chemical adsorption.The main method of carrying out chemical treatment is to uniformly mix specific reagents into the activated carbon.

When adsorption is involved, harmful gases in the air are adsorbed by the activated carbon while some of the gases escape. During use, the adsorption capacity will continue to diminish, and when it weakens to a certain extent, the filter is scrapped. If the adsorption is only physical, heat or water vapour fumigation can be used to remove the harmful gases from the activated carbon and regenerate the activated carbon.

With industrial development and urban expansion, the concentration of harmful gases around us is increasing. And as technology advances and life improves, the demand for pure air is increasing. Thus, the demand for chemical filters is increasing year by year. SNYLI always insists on independent research and development, and can provide chemical filters of various specifications, welcome to inquire!