Cleaning of air filters

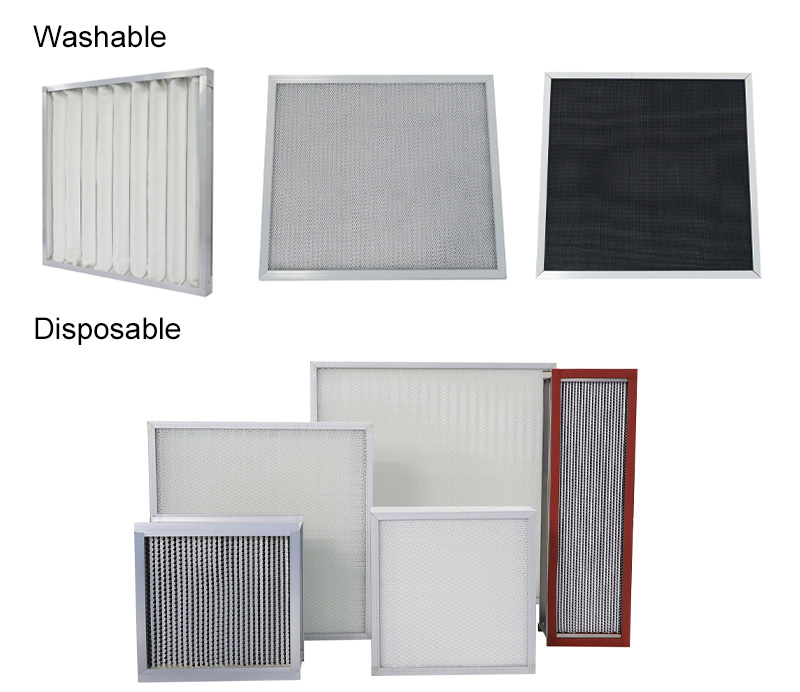

Most filters used for general ventilation and cleanrooms are disposable. They cannot be cleaned at all or are not worth cleaning from an economic point of view.

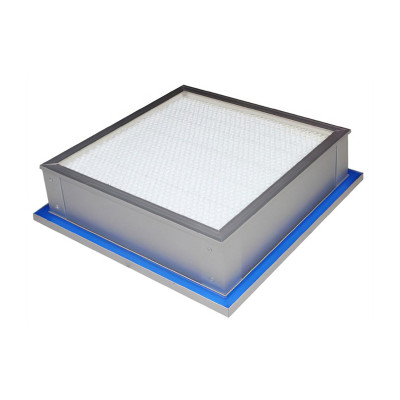

High efficiency filters, the use of the occasion are very careful, the filter, even if the wash can not be broken, it is best not to wash. Unless you have the certainty of thorough cleaning, cleaning performance does not change, and there are experimental means to prove this.

The filtration material of ventilation filters with efficiency above F6, whose fibres are generally between Φ0.5 ~ Φ5mm, is not strong and cannot withstand kneading, therefore, most of the filters above F6 are disposable. In fact, as soon as you look at the filter material, you can tell whether it can be cleaned or not.

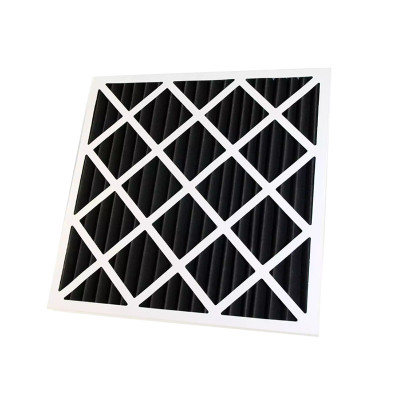

Traditionally, cleaning is said to be done by rinsing with water plus hand rubbing. Therefore, the filter material of washable filter should be strong and the fibre should be thick (diameter ≥Φ10mm). These filter materials are mostly low-priced non-woven fibre mats, which are ideal for manufacturing G2~G4 efficiency filters. Of course, it is also necessary to judge whether the auxiliary material of the filter is water-resistant.

Users in developed countries rarely clean filters, even though some filters are in principle washable. This is due to the high labour intensity of cleaning filters and high labour costs, while the filter is relatively inexpensive. In recent years, more and more users no longer consider the cleaning of the filter.

The materials used for air filtration are mostly hydrophobic chemical fiber materials, and in general, water does not damage the static electricity on the materials. But the added cleaning agent may have an impact on static electricity. For safety reasons, when considering cleaning filters with electrostatic materials, some experiments should be conducted to confirm that water and cleaning agents have no effect on the filtration effect.

Ultrasonic cleaning

Using the principle of ultrasound to clean filters is a great idea. During ultrasonic cleaning, there is no rubbing, and the filtering material is generally not damaged.

In order to cater to environmental protection, some countries have developed assembly lines for cleaning filters with ultrasonic waves, but the current cleaning cost is not much lower than making new filters, so there is no promotion advantage.

If you are interested and have the conditions, you can try ultrasonic cleaning. In recent years, some people have attempted to clean filters with ultrasonic waves, and the biggest problem encountered by those who tried it was sewage treatment, rather than other technical issues as originally envisioned.

Ultrasonic cleaning is not a new technology, but there are new business opportunities for using ultrasonic cleaning to clean filters. At present, the price of cleaned filters in the world is 60% to 70% of the price of new filters (the filters are in good condition and undergo strict performance testing after cleaning).