Information about Clean Workbench

What is the clean bench?

I. Definition

Clean bench, also known as ultra-clean bench, purification bench, ultra-clean table, etc., is a kind of air purification equipment to provide a local high degree of cleanliness of the working environment, and its use has good effect on the improvement of the process environment and product quality and yield.

II. Basic Principle

The indoor air is filtered by the pre-filter, pressed into the static pressure box by the centrifugal fan, and then filtered by the HEPA filter and blown out from the air outlet to form a clean airflow. The clean airflow flows through the working area with uniform cross-section wind speed, thus forming a high clean working environment.

III. Classification

Divided from the airflow direction: vertical flow clean bench and horizontal flow clean bench;

Divided from the number of operators: single person clean bench and double-person clean bench;

Divided from the operating structure: single-side operation and double-sided operation;

Divided from the use: general clean bench and biological clean bench.

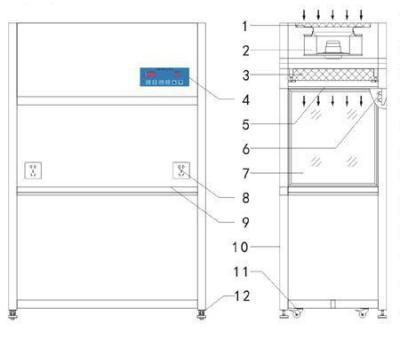

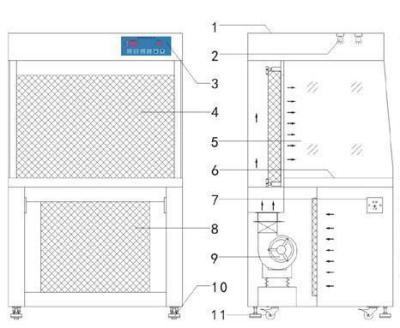

| Vertical Flow Clean Bench | Horizontal Flow Clean Bench | ||

|  | ||

| 1.Primary filter | 2.Centrifugal fan | 1.Box | 2.Lighting |

| 3.HEPA filter | 4.Control panel | 3.Control panel | 4.HEPA filter |

| 5.Multi-hole plate | 6.Lighting | 5.Laminated glass | 6.SS countertops |

| 7.Tempered glass | 8.Socket | 7.Socket | 8.Primary filter |

| 9.SS countertops | 10.Box | 9.Centrifugal fan | 10.Adjust able floor feet |

| 11.Universal wheel | 12.Adjust able floor feet | 11.Universal wheel | |

How to choose a clean bench?

IV. Composition of clean bench

Clean bench is generally composed of box, fan, HEPA filter, electrical controller and other major components, through the interplay of these components, it can create a local unidirectional flow type of dust-free sterile working environment.

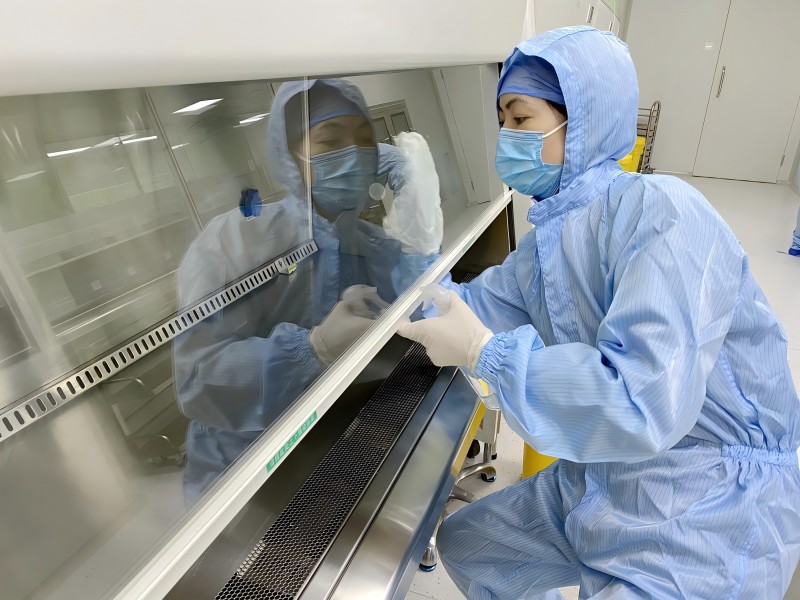

V. Application

According to this feature, clean bench is widely used in medicine and health, biopharmaceuticals, food, medical science experiments, optics, electronics, aseptic laboratory, aseptic microbiological testing, plant inoculation and other needs of the local clean and sterile working environment of the scientific research and production sector.

VI. Selection

Horizontal flow clean bench, the filtered clean air from back to front blowing directly to the operator, mostly used in electronics and precision instruments industry, the impact on health is not great;

Vertical flow clean bench, the filtered clean air from top to bottom blowing to the working surface, mostly used in the biological and pharmaceutical industries, to ensure the safety of the operator.

In addition, according to the actual need, you can also choose single/double person or single/double-sided operation of the workbench.

How to use clean bench?

VII. Placement of the location

Clean workbench should be placed in the location of relatively few people walking around, far away from the door, so that the airflow of the environment around the equipment is relatively stable, will not produce interference on the airflow in the operating area.

VIII. Self-purification and sterilisation before experiment

Every day before use, first turn on the ultraviolet lamp, irradiate the working area, eliminate the microorganisms accumulated on the surface of the operating area, turn off the ultraviolet lamp after 30 minutes, and then turn on the fan to run for 3-5 minutes in order to complete the self-purification.

IX. Cleaning and sterilisation after the experiment

In the process of the experiment, the tools/objects to be used need to be wiped with alcohol first, sterilisation treatment before being put into the workbench, after the operation is finished, attention should be paid to the cleaning of the equipment, especially the table surface, after the cleaning is completed, it is best to turn on the UV lamp for sterilisation before cutting off the power supply.

X. Maintenance and upkeep

According to the cleanliness of the environment, the primary filter should be cleaned or replaced, and the HEPA filter should be replaced; after the lamps and UV lamps have reached the end of their service life, replace them with lamps of the same specification.