Sealing Principle of Gel Seal Filter

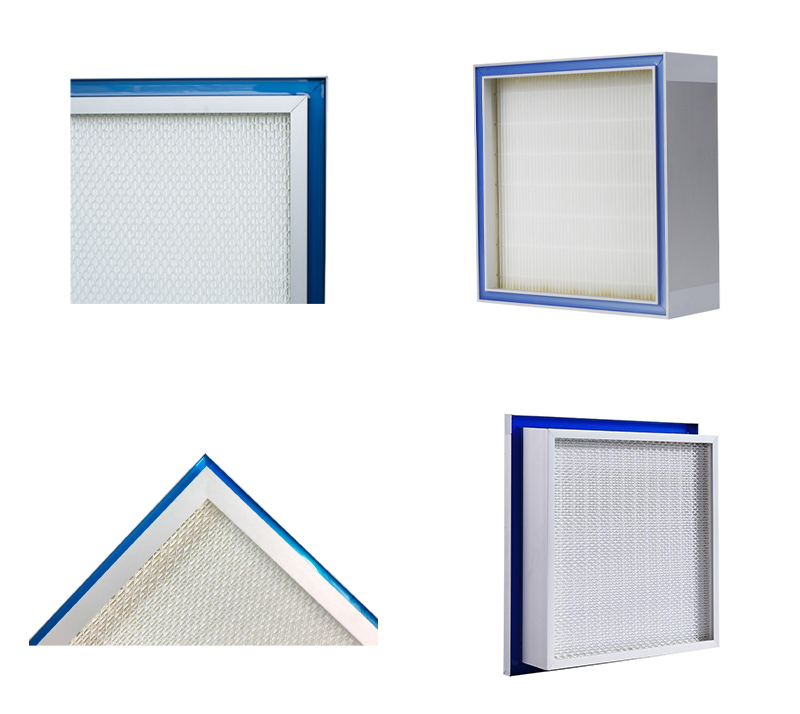

Gel seal HEPA filter is also known as liquid tank HEPA filter. HEPA filter is a kind of purification equipment widely used in water treatment, chemical industry, food and beverage and many other fields.

Sealing Principle

The gel seal is designed to ensure the sealing performance of the filter, preventing air from bypassing the filter and thus causing particles or contaminants to enter.

1. Seal Tank Design. |

HEPA filters are usually assembled from a metal frame combined with ultra-fine glass fibres, with liquid channels located at or around the edges of the filter to fix and seal the filter media. The liquid tank is usually made of rubber, polyurethane or other elastic materials with good sealing performance. |

2. Pressure difference effect. |

HEPA filters work by creating a pressure differential that allows air to pass through the filter media, thereby filtering out particles and contaminants. Under normal operating conditions, the pressure on the inlet side of the filter will be higher than the pressure on the outlet side. Gel sealing can take advantage of this pressure differential effect by forcing air entering the filter through the media without bypassing the filter. |

3. Sealing performance. |

The design of the tank and the choice of materials are critical to sealing performance. The liquid tank must fit snugly into the filter media, ensuring that there are no gaps or holes, to prevent air from bypassing the filter. The sealing tank usually has a certain degree of elasticity, which can adapt to changes in filter dimensions and pressure differences during operation, thus ensuring a durable sealing performance. |

The HEPA filter liquid tank sealing principle relies on the design and material of the sealing tank and the creation of pressure differentials to ensure that air is forced through the filter media for effective filtration. This sealing design improves the efficiency and performance of the filter and ensures effective air filtration.

Two main components

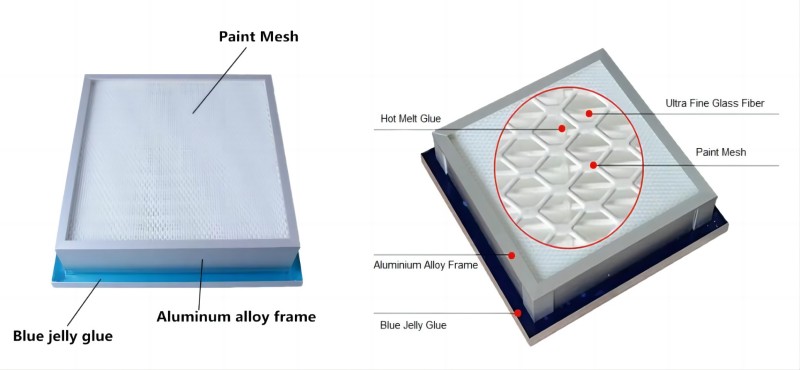

The key to the sealing principle of gel-seal HEPA filters lies in two main components:

1. Liquid Tank. |

| The outer frame of the Gel Seal HEPA filter has a liquid tank located around the perimeter of the filter. This liquid tank is a shallow, elongated channel designed to hold the sealing material. |

| 2. Sealing material. |

Jelly glue ( elastic material ) is placed in the liquid tank, the sealing material is pressed into the liquid tank to ensure a seal is formed with the outer frame of the filter. This sealing material is compressed when the filter is installed, creating a sealed contact surface that prevents air from bypassing the filter. |

The principle of the liquid tank seal is that when a HEPA filter is properly installed and fixed in its application, the sealing material in the liquid tank compresses and creates a tight contact surface with the filter's outer frame. This tight contact surface effectively prevents air from bypassing the filter, forcing air through the filter's tiny voids and fibres to achieve high efficiency filtration.

Due to the gel-sealed design, HEPA filters are able to filter airborne particles and contaminants more effectively, providing higher quality air purification. This seal design helps ensure consistent and reliable filter performance and reduces the frequency of filter maintenance and replacement.

Gel Seal HEPA Filter Application Examples

There are many examples of Gel Seal HEPA filters in practical applications, and the following are some common application scenarios:

| 1. Medical and health care field: |

Widely used in hospital operating rooms, clean wards, laboratories and other medical and health care places with high requirements for air quality. Gel Seal HEPA filters can effectively filter microorganisms, bacteria and viruses in the air, keeping the air clean and aseptic environment. |

| 2. Electronic manufacturing industry: |

In electronic production plants and clean workshops, gel seal HEPA filters are often used to filter fine dust and electrostatic particles in the air, ensure the cleanliness of production equipment and components, and improve production efficiency and product quality. |

3. Food processing industry: |

In food processing factories, food packaging workshops and other places, gel-sealed HEPA filters are used to purify the air, effectively removing odours, microorganisms and particles from the air to ensure food hygiene and safety. |

4.Laboratory environment: |

In laboratories with high air quality requirements, such as biological laboratories, chemical laboratories, etc., the use of gel-sealed HEPA filters can effectively purify the air and maintain the cleanliness of experimental equipment and experimental environment. |

5.Industrial manufacturing field: |

During industrial production, the air may contain a large amount of dust, soot or particles and other harmful substances, the gel-sealed HEPA filters are widely used in all kinds of industrial manufacturing workshops to maintain the cleanliness of the production environment. |

6.Commercial office: |

In commercial office buildings, shopping malls and other public places, in order to provide a fresh and comfortable indoor air environment, gel-sealed HEPA filters are used to purify the air and improve the quality of work and life of employees and customers. |

These examples show the practical application of gel-sealed HEPA filters in different industries and places to provide a healthier and safer working and production environment by effectively filtering and cleaning the air.

Snyli Environmental Technology (Shandong) Co., Ltd has been in the field of air purification for more than ten years, and has obtained a number of patents as well as ISO/CE certificates, which have been recognised and praised by customers in various countries around the world. In the next step, SNYLI will continue to work hard without forgetting its original intention and take pride in providing better products to our customers.

SNYLI can provide customers with professional air purification solutions, air filters, transfer windows, air showers, FFU and other cleanroom equipment can be supplied in one-stop!