Some Technical Notes on Activated Carbon Air Filters

I. Adsorption principle

Activated carbon selectively adsorbs gases rather than mechanically "filtering" impurities.

Activated carbon has a large number of micropores on its surface. When adsorption is involved, harmful gases stick to the inner surface of the micropores due to the gravitational force between molecules. If accompanied by a chemical reaction, the adsorption is called chemical adsorption, otherwise it is physical adsorption. In use, the adsorption capacity will continue to weaken, to a certain extent, the activated carbon scrapped.

Sometimes, heating or fumigation with water vapour can detach harmful substances from the activated carbon and regenerate it.

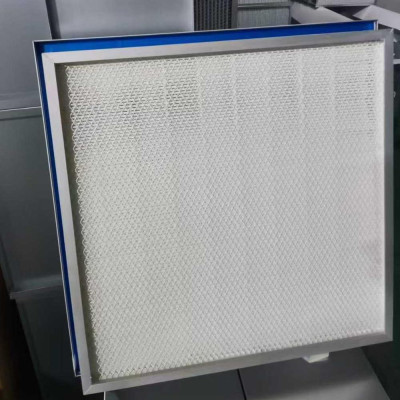

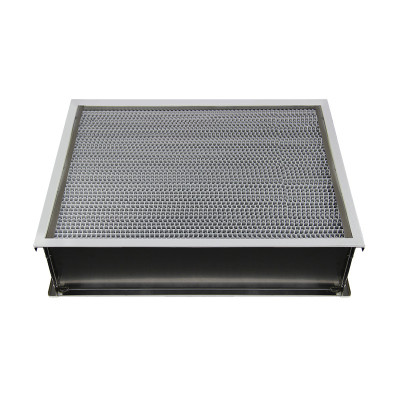

|  |  |

II. Activated carbon materials

Activated carbon materials are divided into granular carbon and fibre carbon.

Traditionally, granular activated carbon includes coal charcoal charcoal, wood charcoal, coconut shell charcoal, and bone charcoal. Sometimes granular charcoal is made into powder, glued to other porous materials, and then processed and moulded.

Fibrous activated carbon is made from carbonaceous organic fibres. It has small pore size, high adsorption capacity, fast adsorption and regeneration. Commonly used fibre substrates are phenolic, plant fibres, polyacrylonitrile and bitumen.

III. Adsorption performance of activated carbon

Adsorption capacity - for a certain gas, the amount that can be adsorbed per unit of activated carbon is called "adsorption capacity". Different materials, or adsorption of different gases, the adsorption capacity is different.

Retention time - The time it takes for the gas stream to pass through the activated carbon layer is called the "retention time". The longer the retention time, the more adequate adsorption. In order to maintain sufficient retention time, the carbon layer should be thick enough, and the filtration air speed should not be too high.

Selectivity - Generally speaking, gases with high molecular weight or high boiling point are easily adsorbed; volatile organic gases are more easily adsorbed than inorganic small molecule gases; chemical adsorption is more selective than physical adsorption. Activated carbon increased the adsorption capacity for specific gases after chemical impregnation.

IV. Selection of activated carbon air filters

The main factors affecting the adsorption efficiency and service life of activated carbon filters are: the type and concentration of pollutants, the air temperature, pressure, relative humidity and retention time.

In actual selection, according to the type of pollutants, concentration and processing air volume and other conditions, to determine the type of activated carbon and filter type.

By monitoring the change in pollutant concentration before and after the filter, it can be determined whether the activated carbon should be replaced. During use, the resistance of the activated carbon filter remains unchanged, but the weight increases, and experienced professionals can determine the service life of the filter based on the weight change.

The upstream and downstream of the activated carbon filter should have good dust removal filters, whose efficiency specification should not be lower than F7. The upstream filter prevents dust from clogging the activated carbon material; the downstream filter removes the dust generated by the activated carbon itself.

V. Main differences between activated carbon air filters and ordinary synthetic fibre filters (non-woven)

| Chemical filter | Fibre Filter |

Adsorption of gas molecules by porous adsorption carriers (absorption reactions) | Interwoven fibres, intercepted and trapped by kinetic and inertial effects of the particles. |

Filter resistance does not vary with the amount of pollutants adsorbed | The resistance of a filter increases with the number of particles being filtered. |

Adsorption of gaseous pollutants cannot be judged by the appearance of the filter. | Interception of dust particles can make the filter media dirty, which can be judged by the appearance of the filter mesh. |

Efficiency decreases with increasing adsorption | The higher the resistance, the better the efficiency. |

Filtering efficiency is related to environmental temperature and humidity as well as pollutant concentration. | Filtering efficiency is independent of environmental temperature and humidity |

Properties to note include: air removal efficiency, longevity, resistance | Properties to note include: efficiency (penetration rate), resistance, longevity |

VI.General Applications

Odour from electronic component factories, food processing factories.

Rotting odour and other odours in hospitals and museums.

Kitchen and bathroom odour.

Paint odour in paint spraying workshop.