Introduction:

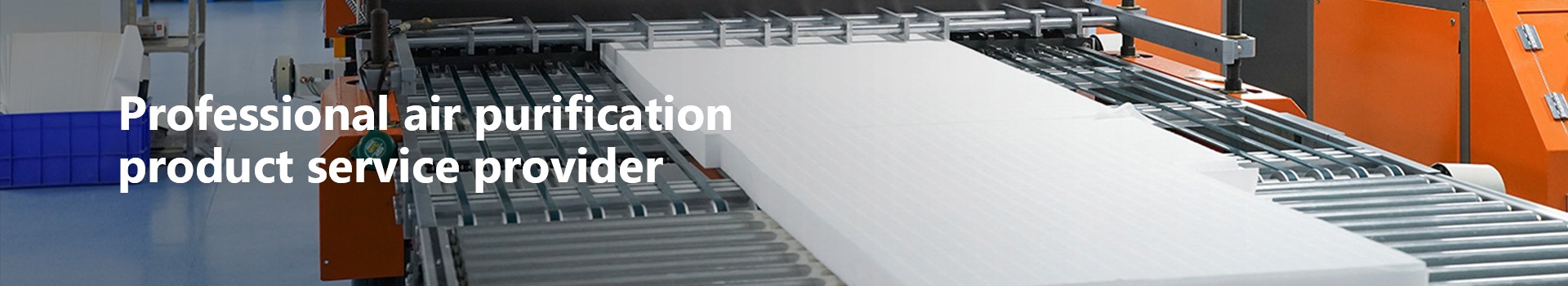

The working principle of a high-temperature air filter is to use the airflow to generate multiple collisions when passing through the micropores or narrow and tortuous channels of the filter element fibers, causing dust particles to be blocked or adhered to the filter element, thereby achieving air purification effect.

Frame material | Stainless Steel |

Filter media material | Ultra fine glass fiber filter paper |

Sealant | Ceramic adhesive |

Gasket | Glass fiber sealing strip |

Divider | Aluminum foil |

Optional thickness | 80,96,120,150,220,292,305 |

Operating temperature | 350℃ |

Using humidity | 100% |

![350 ℃ High Temp Resistant Deep Pleat HEPA Air Filter 350 ℃ High Temp Resistant Deep Pleat HEPA Air Filter]()

Features:

High-efficiency air filter manufacturing technology ensures V-shaped channels.

Aluminium profile frame with anodized surface, inlet and outlet air surfaces with metal grille, sturdy, efficient and easy to handle.

Seamless sealing technology, long sealing effect and not easy to leak, even airflow.

Technical Parameters:

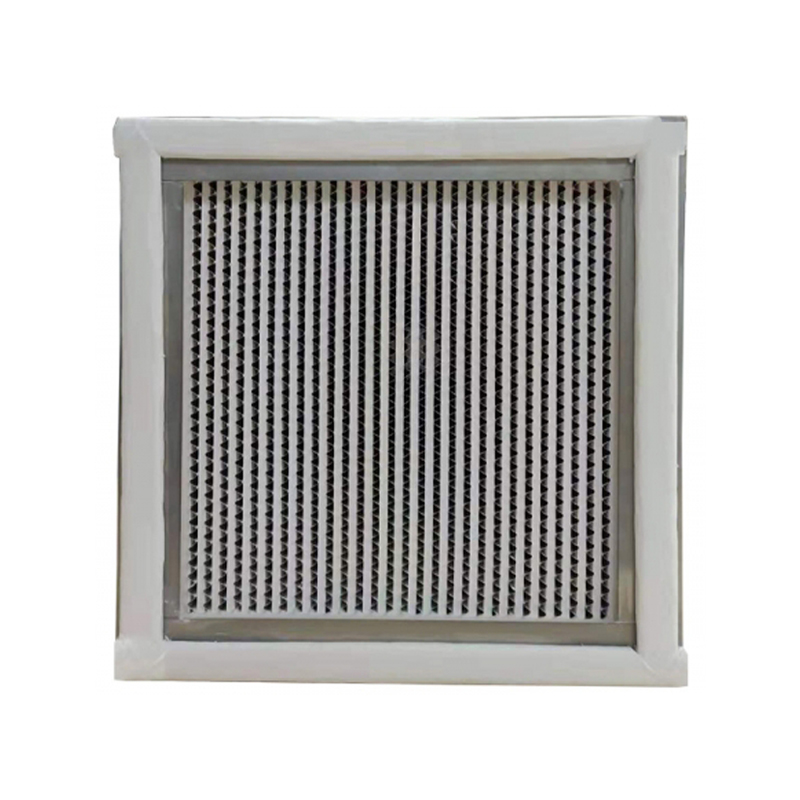

Dimensions(mm) | Rated Airflow(m3/h)/Initial Resistance(Pa) | Filtration Area(m2) | Efficiency Grade |

305*610*150 | 500/190 | 4.7 | H13 |

610*610*150 | 1000/190 | 9.59 |

610*1220*292 | 4450/190 | 42.5 |

610*915*150 | 1500/190 | 0.75 |

610*610*292 | 2200/190 | 21.25 |

610*1220*150 | 2000/220 | 19.17 | H14 |

610*610*292 | 2200/220 | 21.25 |

305*610*292 | 1100/220 | 10.52 |

610*1220*292 | 4450/220 | 42.5 |

Applications:

Due to its high temperature resistance, it can complete the filtration work with quality and quantity in high temperature environments, and effectively avoid damage to the quality of the equipment caused by high temperature environments, allowing the equipment to perform filtration work stably for a long time, so that users can do a good job in production control and cost control. Therefore, the application of high-temperature resistant filters is very extensive.

Multiple occasions that require high cleanliness environments, including aerospace, electronics, semiconductors, biopharmaceuticals, hospitals, food production, and chips.

The end of the air conditioning ventilation system, purification oven, food baking equipment, clean baking room, high-temperature sterilization equipment, high-temperature coating line

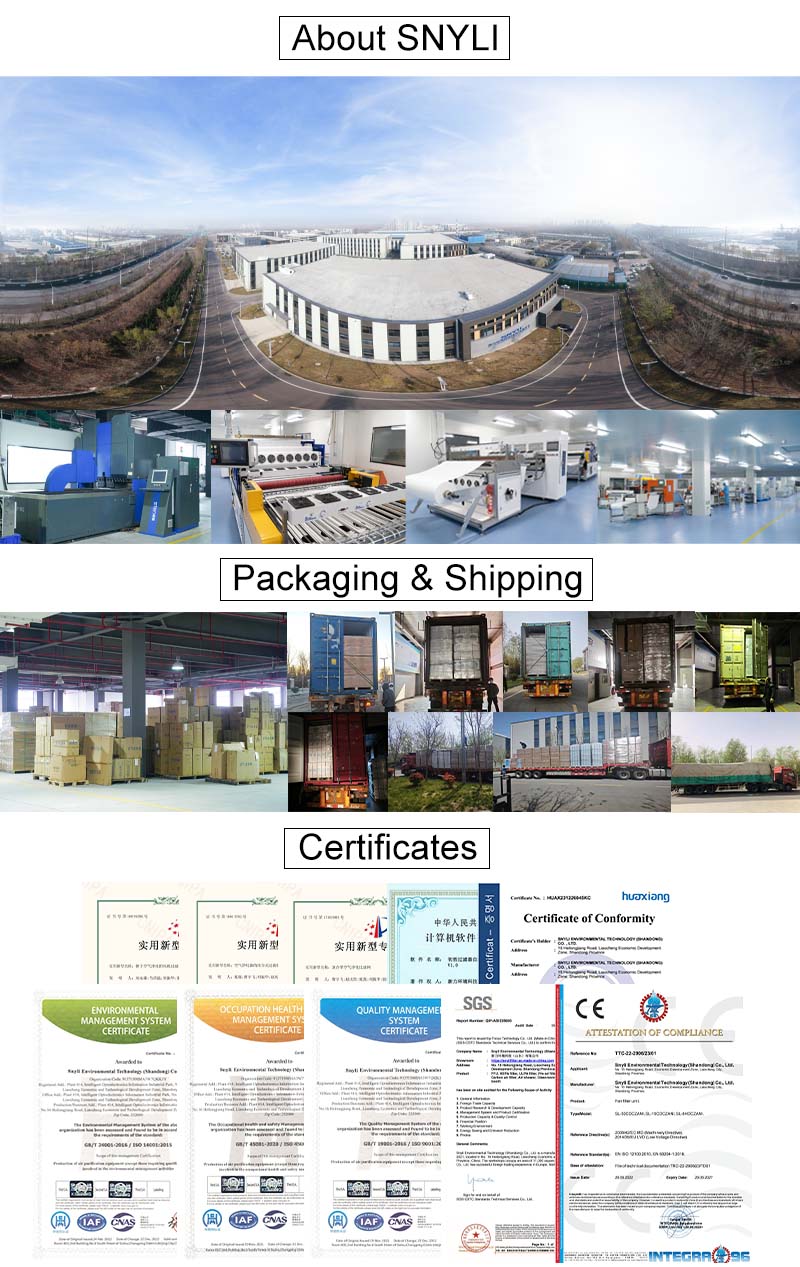

About us:

Snyli Environmental Technology (Shandong) Co., Ltd has more than ten years of experience in R&D and production, with strong strength.

Large scale processing

With more than 20,000 square metres of production base, the annual production capacity is in millions. Automated clean production workshop, independent warehouse, delivery cycle is guaranteed. With professional technical team, more than ten years of industry experience, in-depth application expansion.

High standard production

Strictly in accordance with ISO9001:2015 quality system standards, the introduction of advanced dust particle counters and other inspection and processing equipment to ensure product quality, qualified before being allowed to leave the factory.

Thoughtful service

Professional sales staff to match the demand, after-sales timely follow-up of customer use. Any problems encountered during the use of the product can be put forward to us at any time. Regular tracking of customers, so that customers get a good purchasing experience.

![Snyli Environmental Technology (Shandong) Co., Ltd Snyli Environmental Technology (Shandong) Co., Ltd]()