Introduction:

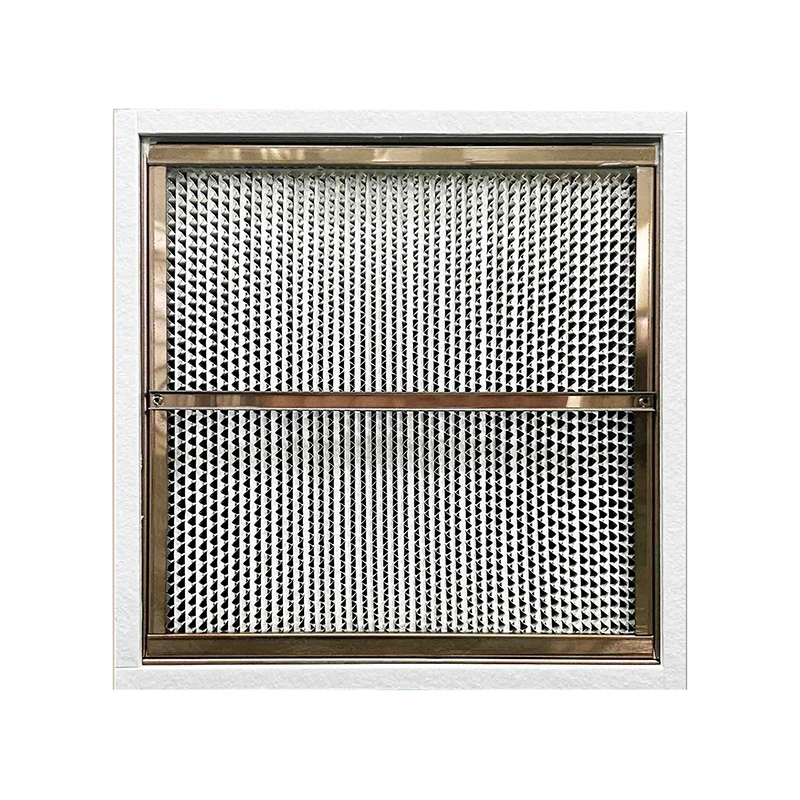

The 350°C High Temperature Filtration Air Filter is a specially designed device for the treatment of high temperature gases and flue gases. These filters are very important in industrial production, especially in the occasions where high-temperature exhaust gases, flue gases or hot air need to be treated.

1. Structural components

a. Filter media

Material: Special high temperature resistant glass fibre is usually used. This material has a very high temperature resistance and is able to remain stable at temperatures up to 350°C.

Characteristics: High temperature resistant glass fibre can not only withstand high temperature, but also has good mechanical strength and chemical stability, which can effectively capture fine particles.

b. Outer frame

Material: Generally made of stainless steel. Stainless steel has excellent corrosion resistance and thermal stability, and can be used for a long time in a high temperature environment without deformation.

Design: The unique design of the outer frame ensures structural solidity and sealing to prevent air leakage.

c. Sealant

Material: Silicone or ceramic adhesive is usually used. These materials can still maintain good sealing performance at high temperatures, preventing untreated air from entering the system through gaps.

Function: Ensure the tight connection between various parts of the filter and improve the overall sealing and reliability.

| Frame material | Stainless Steel |

|---|

| Filter media material | Ultra fine glass fiber filter paper |

|---|

| Sealant | Silicone/Ceramic adhesive |

|---|

| Gasket | Glass fiber sealing strip |

|---|

| Divider | Aluminum foil |

|---|

| Optional thickness | 80,96,120,150,220,292,305 |

|---|

| Operating temperature | 350℃ |

|---|

| Max. Humidity | ≦ 100% RH |

|---|

![350℃ High Temperature Filtration Air Filter 350℃ High Temperature Filtration Air Filter]()

2. Working principle

Air inlet: High temperature air enters into the filter from the air inlet.

Filtration process: When the air passes through the high-temperature resistant glass fibre filter media, the particles are trapped by the filter media, and the purified air is discharged from the air outlet.

Outlet: The purified air is discharged through the outlet, which can be further processed or discharged into the atmosphere.

3.Common dimensions:

Dimensions (mm) | Rated Airflow(m3/h)/ Initial Resistance (Pa) | Filtration Area (㎡) | Efficiency Grade |

305*610*150 | 500/190 | 4.7 | H13 |

610*610*150 | 1000/190 | 9.59 |

610*1220*292 | 4450/190 | 42.5 |

610*915*150 | 1500/190 | 0.75 |

610*610*292 | 2200/190 | 21.25 |

610*1220*150 | 2000/220 | 19.17 | H14 |

610*610*292 | 2200/220 | 21.25 |

305*610*292 | 1100/220 | 10.52 |

610*1220*292 | 4450/220 | 42.5 |

4. Features

a. High temperature resistance

Able to work normally under the temperature of 350℃, suitable for various high temperature operation scenarios.

b. High efficiency filtration

Even under high temperature conditions, it can maintain high filtration efficiency, effectively removing dust particles and other pollutants from the air.

c. Stable and durable structure

The stainless steel frame provides enough strength and stability to maintain no deformation under long time high temperature environment.

d. Good sealing

The use of silicone or ceramic adhesive for sealing treatment ensures that good airtightness is maintained when there are large changes in temperature.

e. Low maintenance cost

Due to the reasonable choice of materials and advanced manufacturing process, these filters usually have a long service life, reducing the need for frequent replacement.

f. Wide range of application

350°C High Temperature Filtration Air Filter is especially suitable for various industrial fields that require purification of high temperature air, such as iron and steel mills, power plants, chemical plants, etc.

![350℃ High Temperature Filtration Air Filter 350℃ High Temperature Filtration Air Filter]()

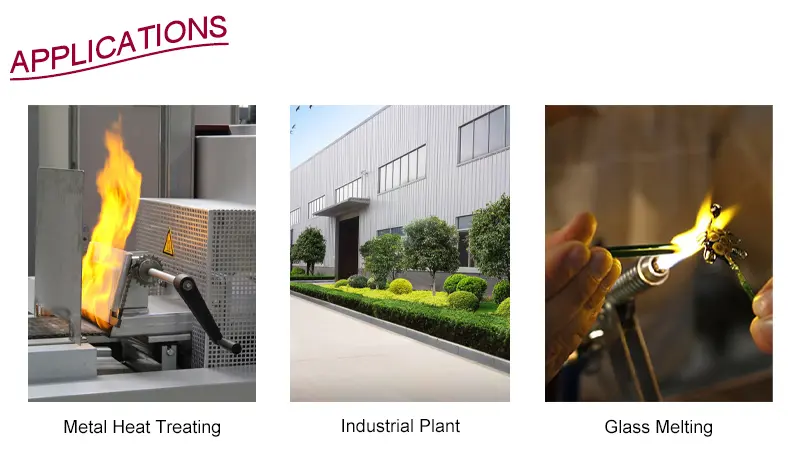

4. Areas of application

Iron and steel industry: treatment of high-temperature flue gas produced by blast furnaces, converters, etc.

Power industry: high-temperature waste gas produced by coal-fired power plants, gas turbines, etc.

Chemical industry: high-temperature gases produced by reaction kettles, cracking furnaces, etc.

Cement industry: treatment of cement kiln exhaust gas.

Other industries: including but not limited to metallurgy, glass manufacturing, ceramic firing and other places that need to deal with high-temperature gases.

![Applications Applications]()

5. Precautions

Regular inspection: Although the high-temperature resistant filter has a long service life, it is still necessary to regularly check the wear and tear of the filter media and the state of the sealant to ensure its normal operation.

Correct installation: Installation should be carried out in strict accordance with the regulations to ensure that all parts are correctly connected and well sealed.

Operating conditions: Although the high temperature resistant filter is designed for use in high temperature environments, it should be avoided to be used beyond its rated temperature range in order to prolong its service life.

In conclusion, 350℃ High Temperature Filtration Air Filters play an important role in many industrial fields due to their excellent temperature resistance, high efficiency filtration capacity and long and stable service life.

About SNYLI:

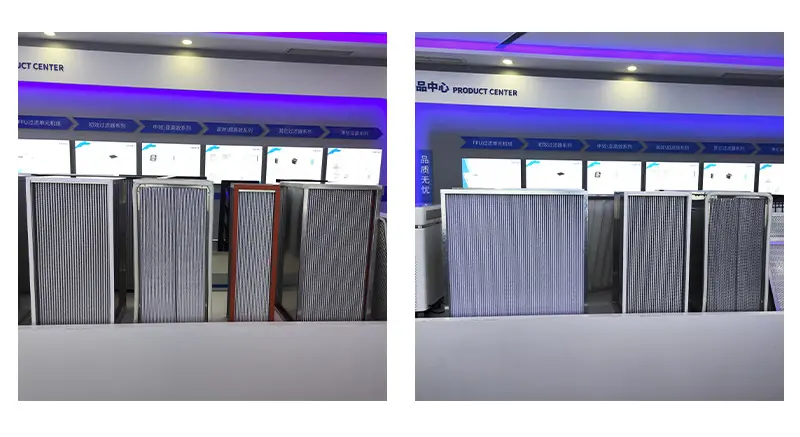

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, registered in Liaocheng City, Shandong Province, mainly engaged in air filtration products. Since the establishment of our company, we have been continuously deepening our research and development to improve our strength, and now we have mastered many patents and obtained ISO/CE certificates.

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.

![SNYLI Production Workshop SNYLI Production Workshop]()

After more than ten years, SNYLI has set up branches in many places in China and a trading company in Jinan City, Shandong Province. At present, SNYLI products have been exported to both home and abroad, and we have signed long-term co-operation agreements with customers in many countries.

We always put the interests of customers in the first place, regularly follow up customer feedback, and strive to improve our own strength, and the constant pursuit of progress.

Giving us a chance to co-operate will be a decision that benefits both parties! SNYLI welcomes your enquiry!

![SNYLI FACTORY SNYLI FACTORY]()