Introduction:

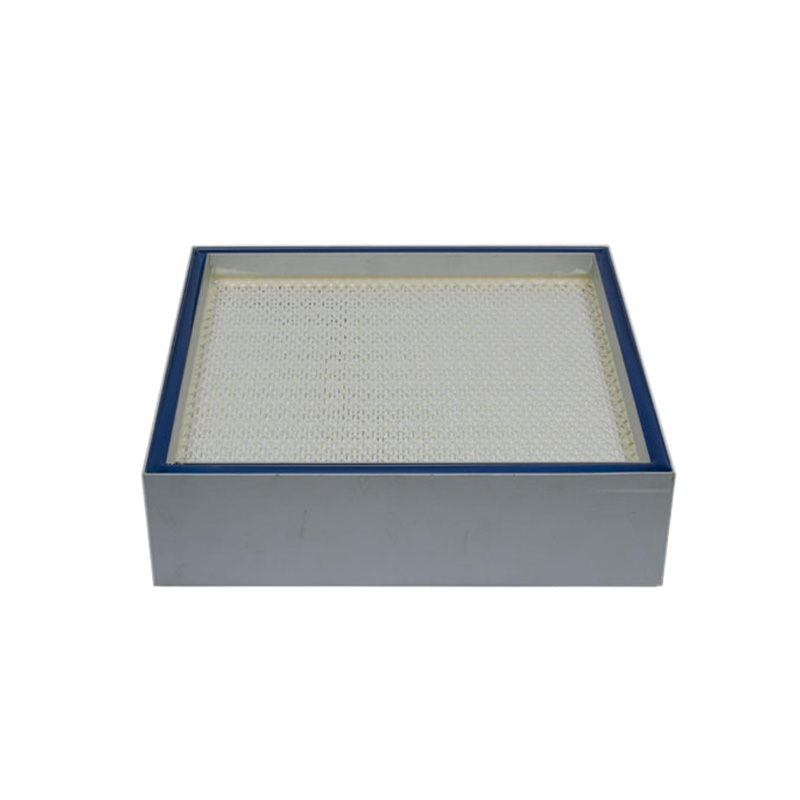

Gel seal ULPA filter is a kind of production equipment widely used in water treatment, chemical industry, food and beverage and many other fields. Among these, the liquid tank sealing principle is the key to the filtration efficiency of HEPA filters.

The design of the liquid tank ULPA filter helps ensure proper filter operation and prevents air from bypassing the filter and causing contamination.

| Frame | Anodized aluminum profile / Galvanized steel / Aluminum profile / Stainless steel |

|---|

| Media | Ultra fine glass fiber |

|---|

| Separator | Hot melt adhesive |

|---|

| Sealant | Urethane gel sealant |

|---|

| Std. EN1822:2009 | H13 / H14 / U15 |

|---|

| Efficiency | 99.99%,99.999% at 0.3μm, 99.9995% at 0.12μm (DOP/PSL/PAO Counting method) |

|---|

| Maximum temperature | 70℃ |

|---|

| Maximum relative humidity | 100% |

|---|

| Customized size | Available |

|---|

![HVAC Gel Seal ULPA Filter HVAC Gel Seal ULPA Filter]()

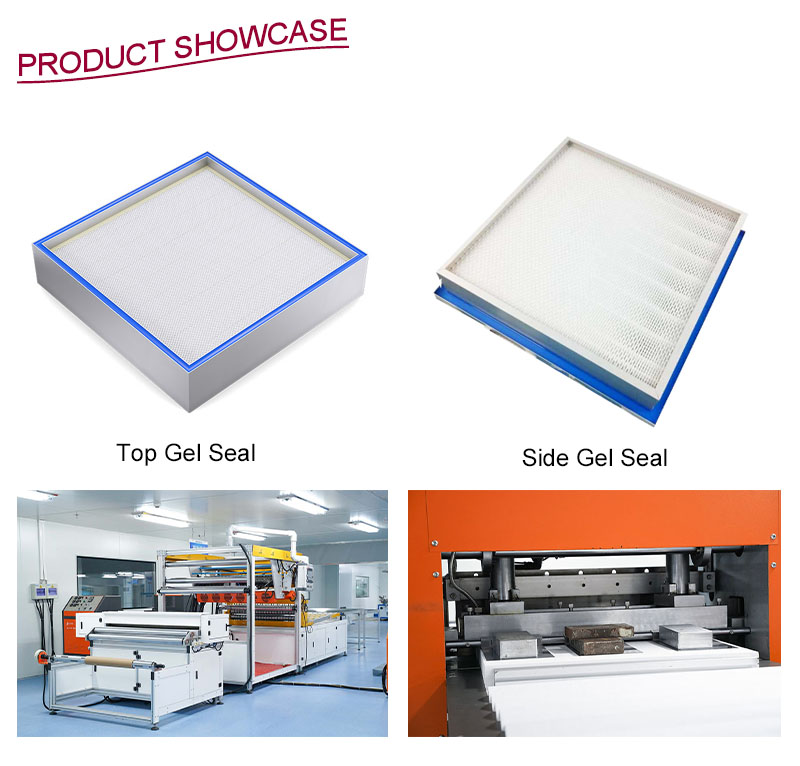

Principle of liquid tank seal:

The liquid tank seal is designed to ensure the sealing performance of the filter, preventing air from bypassing the filter and bypassing particles or contaminants.

1. Seal groove design: HEPA filters usually consist of a metal outer frame that encases the filter media within it. Liquid tank is located at or around the edges of the filter to hold and seal the media. The liquid tank is usually made of rubber, polyurethane or other elastic materials with good sealing performance.

2. Differential pressure effect: HEPA filters work by creating a pressure differential that allows air to pass through the media, thereby filtering out particles and contaminants. Under normal operating conditions, the pressure on the inlet side of the filter will be higher than the pressure on the outlet side. The liquid tank seal utilizes this differential pressure effect to force air entering the filter through the media without bypassing the filter.

3. Sealing performance: the design of the liquid tank and the choice of materials is critical to the sealing performance. The liquid tank must fit closely to the filter media to ensure that there are no gaps or holes to prevent air from bypassing the filter. The sealing channel is usually resilient to accommodate changes in filter size and pressure differentials during operation to maintain a durable seal.

Common Dimensions:

Liquid Tank Type | Frame thickness (mm) | Rated resistance(Pa) | Rated surface wind speed (m/s) |

H13 | H14 | U15 | U16 |

Top Liquid Tank | 81 | 105 | 110 | 120 | 140 | 0.45

|

94 | 90 | 95 | 105 | 125 |

104 | 75 | 80 | 90 | 110 |

Side Liquid Tank | 69 | 105 | 110 | 120 | 140 | 0.45 |

93 | 75 | 80 | 90 | 110 |

Performance Features:

1. High filtration efficiency: adopting high quality ultra-fine glass fiber as the filter material, it can effectively filter particles and harmful substances in the air and ensure that the air quality reaches a high standard.

2. Good sealing: the gel seal design can ensure that the air must be filtered through the filter, preventing bypassing the filter directly into the air system.

3. Long life: the metal frame, high-quality fiberglass filter media and gel sealing material have a long service life and are not easy to age and deform, which can maintain the filtration efficiency for a longer period of time.

4. Environmentally friendly and healthy: the gel filter material is non-toxic, odorless, non-polluting, and harmless to the environment and users' health.

5. Wide range of application: It is suitable for all kinds of environments and industries that need high efficiency, stability and long life air filtration requirements, such as hospitals, laboratories, electronic manufacturing and so on.

Application Scenario:

1. Medical and health care field: hospital operating rooms, clean rooms, laboratories and other places that require high purity air, used to ensure the cleanliness of the surgical environment and experimental environment.

2. Electronics manufacturing industry: semiconductor production, electronic device production and other places with strict air quality requirements, can provide clean air, preventing micro-dust, static electricity and other effects on the product.

3. Food processing industry: food production workshops, catering establishments and other places that require high standards of air purification to ensure food safety and hygiene.

4. Public places: movie theaters, shopping malls, office buildings and other densely populated public places, providing clean air and improving indoor air quality.

5. Home and office environment: homes, offices and other places of daily life and work, to provide clean and healthy air and improve the living and working environment.

6. Industrial production areas: automobile manufacturing, aerospace, chemical and other types of industrial production places, can prevent airborne particles and pollutants on equipment and products.

![Applications Applications]()

About us:

Snyli Environmental Technology (Shandong) Co.,Ltd has always insisted on putting customers' interests in the first place, since its establishment, SNYLI has gone through more than ten springs and autumns, and successfully established long-term co-operation with hundreds of domestic and foreign enterprises. In addition, SNYLI always adheres to the principle of advancing with the times, and has already obtained a number of R&D patents, and has been cooperating closely with industry associations, university research institutes, and third-party laboratories for a long time.

SNYLI is committed to the field of dust-free purification, and has rich experience and deep technical strength in this industry. If you have such needs, please feel free to enquire!

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()