Introduction:

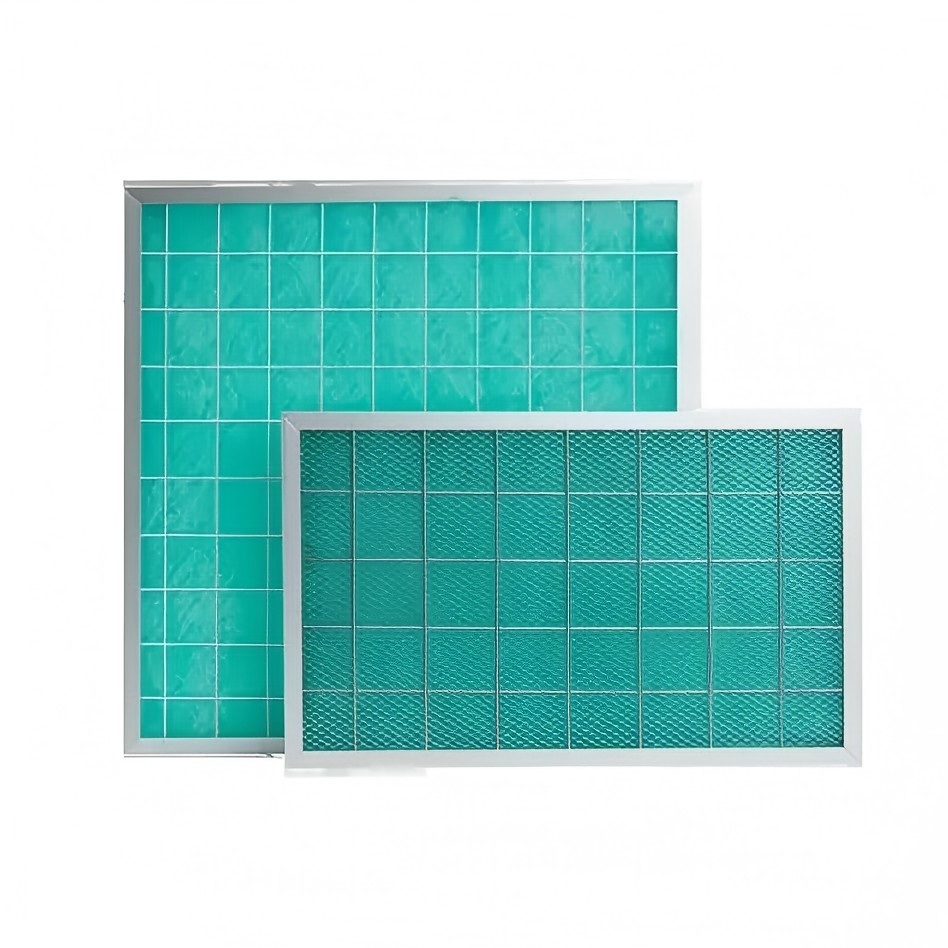

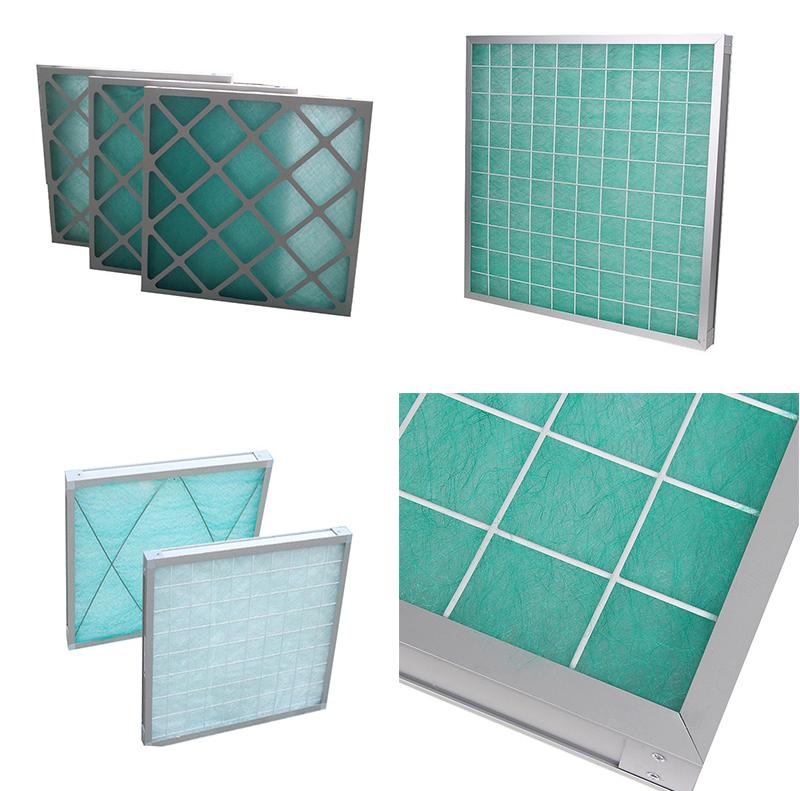

The Painting booth filter is a key component specially designed for spray booths. Its main function is to efficiently capture and remove over-spray mist, dust and other pollutants in the air during the spraying process. It can effectively protect the equipment in the spray booth, ensure the quality of spraying, improve the working environment, and guarantee that the discharged air meets environmental protection standards.

Frame material | Cardboard / Aluminium / galvanised frame |

Filter material | Made of highly elastic, fracture-resistant glass fibre with an increasing fibre structure. |

Efficiency | G3,G4,M5 |

Temperature resistance | 170℃ |

Applications | Pre-filtration for air conditioning and painting systems, paint spraying systems and workshops |

![Painting booth filter Painting booth filter]()

Common Model:

External Dimensions (mm) | Rated air volume (m3/h) | Initial pressure loss (Pa) |

290*595*46 | 3400 | 135 |

490*595*46 | 2000 | 135 |

595*595*46 | 1500 | 85 |

Advantages:

1. Improve the working environment and health

Effectively remove chemical fumes, volatile organic compounds and harmful particulate matter from the air, providing workers with a healthier and safer breathing environment and ensuring the occupational health of employees.

2. Save comprehensive costs

Filters with high dust holding capacity have a longer replacement cycle, reducing the consumption of consumables and downtime for replacement. At the same time, keeping the ventilation system unobstructed can reduce the energy consumption of fans, thereby saving operating costs.

3. Enhance production efficiency

Stable air flow and a clean working environment reduce the need for rework and overhaul, making the spraying process smoother and faster, and directly enhancing production efficiency and capacity.

These advantages collectively constitute the indispensable value of the spray booth filter, which is a key link to ensure efficiency and quality in any professional spraying operation.

Applications:

1. Automotive industry: Used in automotive manufacturing, maintenance and modification workshops.

2. Metal processing and coating: Widely used in the spraying lines of mechanical equipment, metal furniture and sheet metal parts.

3. Wood and furniture manufacturing: Surface spray painting booths for furniture, cabinets and wood products.

4. Aerospace: Applied in the spraying and repair workshops of aircraft components and complete aircraft.

5. General manufacturing industry: Any field involving industrial spraying, such as the spraying of electronic product casings and plastic components, etc.