Introduction:

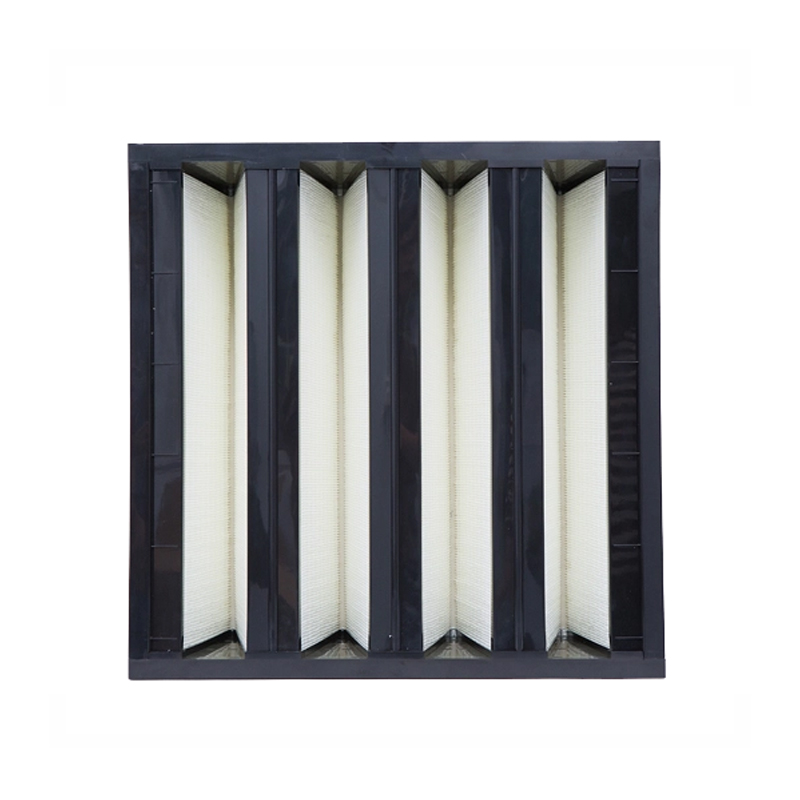

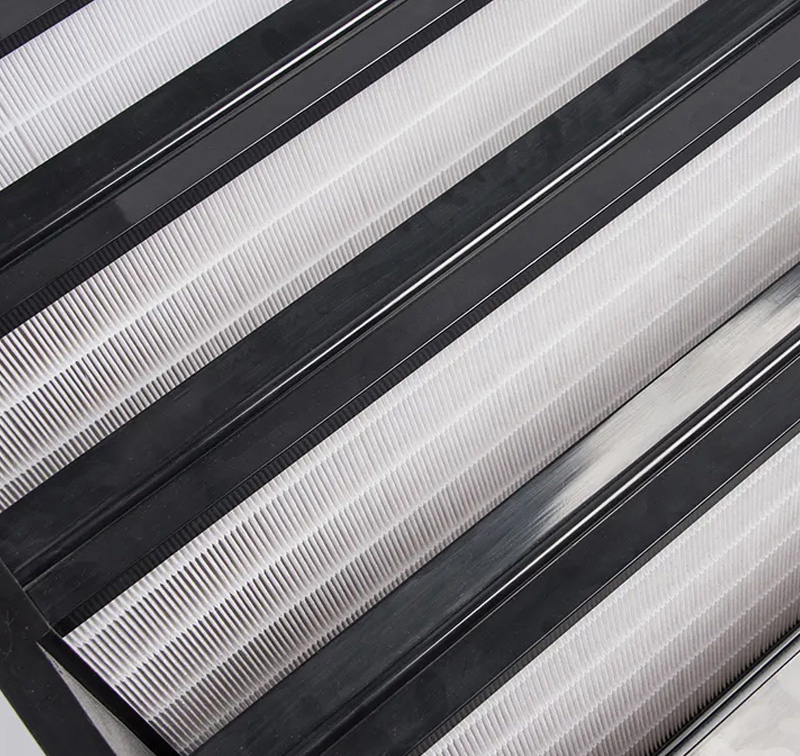

Compact Cassette Filter (Compact V-Bank Filter) is an air filter with a deep V-shaped pleated design, a sturdy structure and ultra-high filtration efficiency. It can achieve aseptic filtration of H13 and above levels in a compact space.

| Frame | ABS plastic frame, aluminium frame, galvanised frame |

Filter material | Glass Fibre / PP |

Separator | Hotmelt adhesive |

Sealant | Polyurethane |

Airtight sealing strip | EVA, EPDM |

Max. temperature | 70℃ |

Max. humidity | 100% RH |

![Compact Cassette Filter Compact Cassette Filter]()

Common Model:

Model | Actual size

W×H×D(mm) | Air flow

(m³/h) | Initial

pressure drop (Pa)

| Final

pressure drop(Pa) |

Box type | H4VH305610292 | 305×610×292 | 1700 | 249Pa

Face velocity 0.85m/sec | 500Pa

*Proposed value |

H4VH610610292 | 610×610×292 | 3400 |

Single flange type | H4VH287592292 | 287×592×292 | 1700 | 265Pa

Face velocity 0.45m/sec | 220Pa

*Proposed value |

H4VH592592292 | 592×592×292 | 3400 |

Advantages:

Compact Cassette Filter has many irreplaceable advantages

1. It has a large dust holding capacity and a long service life

The huge filter material area enables dust to be more evenly dispersed and accommodated, resulting in a slow increase in pressure drop. This extends the service life, reduces the frequency of replacement and maintenance costs.

2. Good economy

Although the cost of a single purchase may be relatively high, the overall benefits brought by its long lifespan, low maintenance cost and space-saving make its full life cycle cost more competitive.

In conclusion, the Compact V-Bank Filter is an ideal choice for achieving a high-level clean environment, saving space and reducing long-term operating costs.

![Compact Cassette Filter Compact Cassette Filter]()

Applications:

Compact Cassette Filter is mainly applied in occasions with extremely high requirements for air cleanliness:

1. Terminal supply air in the clean room

Compact filter is widely used in clean rooms in fields such as electronics, semiconductors, medicine, and biosafety laboratories, serving as an end-of-line high-efficiency filtration device for the air supply system.

2. Pharmaceuticals and Biotechnology

V bank filter is used in key process areas such as aseptic preparation workshops, filling lines, and vaccine production workshops to ensure the aseptic requirements of the production environment.

3. Hospitals and medical facilities

Installed in operating rooms, bone marrow transplant wards, icus, sterile preparation centers, etc., it effectively controls pathogenic microorganisms and prevents cross-infection.

4. High-end electronic manufacturing industry

Provide a super-clean air environment for production lines such as chip manufacturing, liquid crystal panels, and precision instruments that have "zero tolerance" for fine dust.

5. Food and beverage industry

It is used in aseptic packaging workshops, fermentation workshops, etc., to prevent products from being contaminated by microorganisms.

![Compact Cassette Filter application fileds Compact Cassette Filter application fileds]()

Packaging & Shipping

Secure Packaging, Reliable Delivery – Your Trust, Our Commitment

We understand that air filters require good protection during transit. That's why we adopt a multi-layered packaging approach:

Robust Outer packaging: Custom-sized, carton box+wooden pallet for maximum impact protection.

Inner Stabilization: High-density foam and anti-shock materials to prevent movement and vibration damage.

Clear Labeling: Each package is marked with product name, model, pcs.

Our global shipping network ensures timely delivery, whether by sea, air, or land. We work with trusted partners to provide real-time tracking and flexible shipping terms—FOB, CIF, or EXW—to meet your needs.

![SNYLI packaging&delivery SNYLI packaging&delivery]()

About Us

Innovating Air Filtration – For a Cleaner, Safer Industrial World

With over 15 years of expertise, we are a leading manufacturer of high-efficiency industrial air filtration systems. Based in China and serving clients across North America, Europe, Asia,Africa, we specialize in designing and producing filters for demanding sectors such as pharmaceuticals, automotive, food processing, and electronics.

Our state-of-the-art facility combines automated production with strict quality control. We hold ISO 9001 and ISO 14001 certifications, and our products meet international standards including UL, CE. From HEPA and ULPA filters to activated carbon and custom solutions, we deliver performance you can rely on.

![SNYLI Factory SNYLI Factory]()

Why Choose Us

Quality, Customization, and Global Support – Your Ideal Filtration Partner

Superior Performance: Our filters deliver >99.97% efficiency with low resistance, reducing energy costs.

Tailored Solutions: We customize dimensions, materials, and specifications to fit your unique system.

Competitive Pricing: Direct-factory pricing with no intermediaries, offering exceptional value.

Quick Lead Times: Efficient production planning ensures on-time delivery, even for urgent orders.

Expert Support: Our engineering team provides technical guidance and after-sales service worldwide.

Choose us for reliable products, seamless cooperation, and a partnership built on trust.