Introduction:

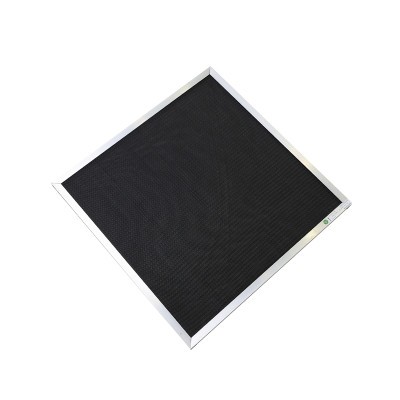

Paint spray booth air filter media is a filter media specially designed to filter and purify the air inside the paint spray booth to ensure that the air is clean and free of contaminants during the painting process. It effectively reduces the risks posed by harmful airborne gases and particles and avoids the effects of exogenous contaminants such as dust on painted surfaces.

Media | Glass fiber |

Efficiency | G4 (EN 779) / MERV 8 (ASHRAE 52.2) |

Max. Temperature | 170°C |

Max. Relative Humidity | 100% RH |

![Paint Spray Booth Filter Media Paint Spray Booth Filter Media]()

Common dimensions:

Model | SN-50/60 | SN-100 |

Avg.arrestance(acc.EN779) | 92%~96% | 97%~99% |

Initial pressure drop | 15Pa | 20Pa |

Final pressure drop | 250Pa | 280Pa |

Air velocity | 0.7-1.75m/s | 0.7-1.75m/s |

Maximum Dust Capacity | 3200-3600g/m2 | 3600-4900g/m2 |

Temp.resistance, const | 170℃ | 170℃ |

Temp.short peaks | 190℃ | 190℃ |

Common thickness | 50/60mm | 100mm |

Roll sizes standard | 0.8*20,1.0*20,2.0*20 | 0.8*20,1.0*20,2.0*20 |

Performance Characteristics:

1.High efficiency filtration, can effectively remove dust, particles, odour and other pollutants in the air.

2. High filtration efficiency, ensure the air quality during the painting operation.

3. Durable and stable, the effect is continuous and stable in long-term use.

4. Easy to install and maintain, easy to operate.

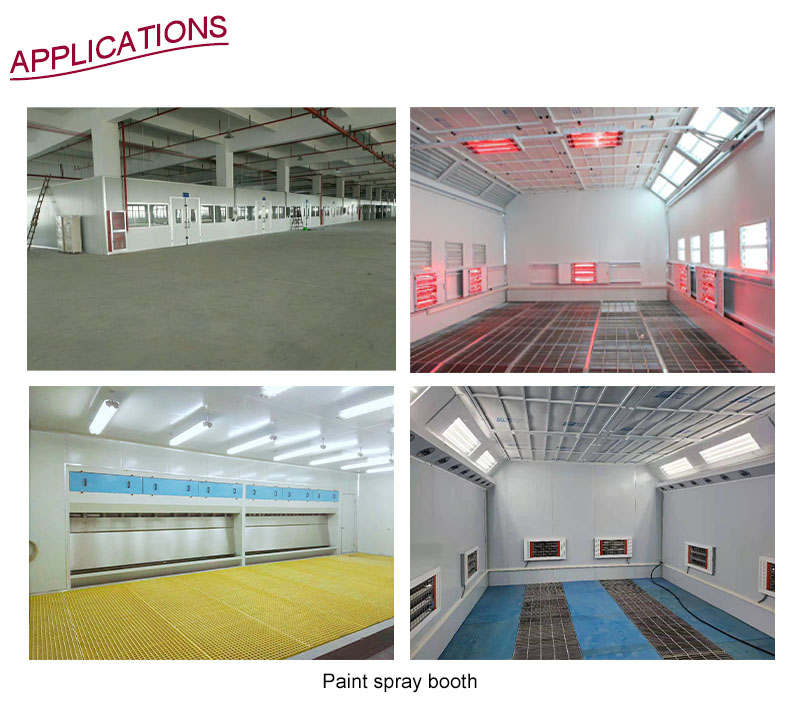

Application Scenario:

Paint spray booths in automobile manufacturing and repairing industries.

Spraying workshop in metal processing factory and industrial enterprises.

Spraying operation sites in furniture manufacturing, building decoration and other fields.

Any work environment where spraying operations are required and air quality is important.

![Application Application]()

Precautions for use:

Regularly check and replace the air filter to ensure that its filtration effect is normal.

Observe the operating procedures and correctly use and maintain the air filter.

Pay attention to the installation position and method of the air filter to ensure its working effect.

Pay attention to the cleaning and maintenance of the air filter to avoid clogging and affecting its normal work.

About us:

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, after more than ten years of development, now has a number of national patents and ISO/CE certificates.SNYLI can provide customers with high-quality products and services, and has always been to research and development of better quality products as the goal.

Producer of raw materials. Our own production, quality assurance, affordable price. Meanwhile, we provide professional air filtration solutions.

Strong technical strength. We have high-end technical talents and first-class production equipment.

Strong customization strength. We provide customized service and can provide samples for you to test.

Perfect product testing system. Strict quality inspection standards make us always unchanging requirements.

Perfect after-sales service system. One-stop service experience and regular customer return visits make you worry-free after-sales.

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()