Introduction:

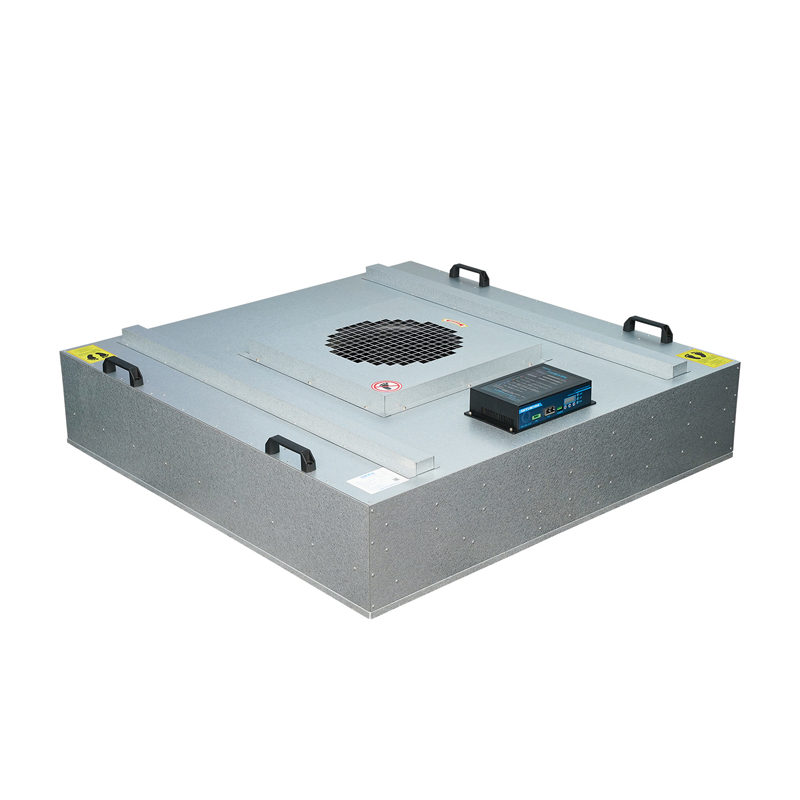

Fan filter unit mainly consists of fan, high efficiency or ultra-high efficiency air filter, housing and control unit. The main materials of the housing are: standard coated steel plate (including galvanised, aluminium-zinc plated, sprayed, etc.); stainless steel plate; aluminium plate (aluminium alloy plate). There are two main types of current methods, DC and AC, and this article focuses on fan filter units for DC motors.

![DC Type HEPA Fan Filter Unit DC Type HEPA Fan Filter Unit]()

Technical parameters:

Model | Housing dimension mm (H×W×D) | Filter dimension mm (H×W×D) | Filter efficiency | Motor efficiency |

SL-30CDCZPN1 | 1174×1174×300 | 1170×1170×70 | ULPA/HEPA | 88% |

SL-15CDCZPN1 | 574×1147×265 | 570×1170×70 | ULPA/HEPA | 88% |

Component details:

Housing

Commonly used aluminum-zinc plating, stainless steel, aluminium alloy. The thickness of the housing is generally around 0.8mm to 1.2mm.

Air Filter

There are two kinds of air filters: HEPA and ULPA filters, which are selected according to the actual needs of customers.

Airflow Equalisation Device

With the continuous development of technology, airflow equalisation device is assembled in FFU to adjust the airflow at the outlet, so as to improve the airflow distribution in the cleanroom.

Currently, there are roughly three types of such equalisation devices. The first is the orifice plate, mainly through the distribution of sparse and dense holes on the plate to regulate the outlet airflow of the FFU. The second is a grille, mainly through the sparse density of the grille to regulate the outlet airflow of the FFU. The third is the power curve, mainly through the shape of the curve to induce the flow of airflow, but also through the distribution of holes on the curve to regulate the airflow.

Air Duct Connection Components

At lower cleanliness levels (below Class 1000, Federal Standard 209E), where there is no static pressure box in the upper part of the ceiling, FFUs with air duct connection components make it easy for air ducts to be connected to the FFU.

Metal Protection Mesh

Mainly for the protection of the filter. Most of them are anti-static, usually aluminium alloy mesh.

The Motor

DC motors are expensive but easier to control, energy efficient, stable in operation and low noise.

Applications:

Mainly used in places with strict requirements for clean air, mainly applied to clean rooms in semiconductors, electronics, flat panel displays and bio-industry, etc. It can also be applied to clean rooms, clean operating tables, clean production lines, assembled dust-free and some other occasions. The use of fan filter unit can make simple clean workbench, clean transfer cabinet and clean storage cabinet.

About us:

Snyli Environmental Technology (Shandong) Co., Ltd is a well-known manufacturer in the air purification industry in Northern China and has gained continuous support from many large customers. A number of patents have been obtained as well as ISO/CE certificates.

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()