Introduction

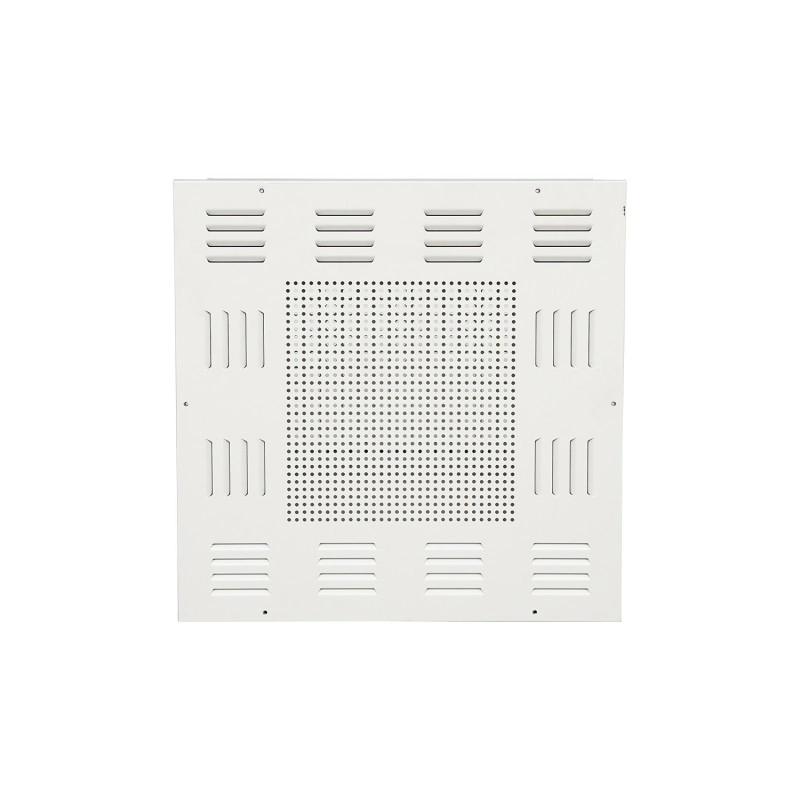

HEPA Box is a key type of equipment used in a clean room or clean area, mainly to provide high efficiency filtered clean air to ensure that the concentration of particles and microorganisms in the environment meets the requirements. It is usually installed in the ceiling of a cleanroom and filters the air through HEPA or ULPA to create a unidirectional flow (laminar flow) to maintain cleanliness.

Specific structure |

Housing | usually made of stainless steel or galvanised steel, corrosion resistant and easy to clean. |

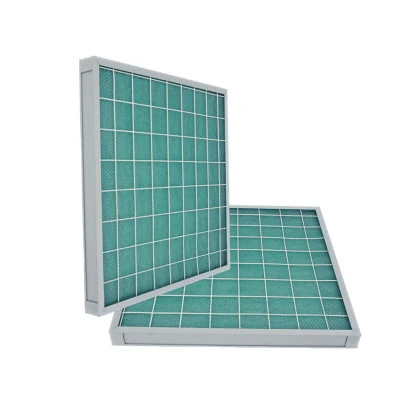

HEPA filter | the core component, with a filtration efficiency of 99.99% or more, used to remove particles and microorganisms from the air. |

Diffuser plate | located at the air outlet to ensure even distribution of airflow and avoid eddy flow. |

Air valve | regulates the air supply volume and controls the pressure difference and airflow speed in the clean area. |

![HEPA box HEPA box]()

Common dimensions:

Model | Air flow (m³/h) | Top inlet duct type Box dimension(mm) | Side inlet duct type Box dimension(mm) | HEPA filter Dimension (mm) | Inlet duct Dimension (mm) |

GKF-5A | 500 | 465×465×280 | 465×465×450 | 400×400×95 (Top gel sealing ) | 200×200 |

GKF-10A | 1000 | 615×615×280 | 615×615×450 | 550×550×95 (Top gel sealing) | 200×320 |

GKF-15A | 1500 | 695×695×280 | 695×695×450 | 630×630×95 (Top gel sealing) | 250×320 |

GKF-20A | 2000 | 675×980×280 | 675×980×450 | 610×915×95 (Top gel sealing) | 250×500 |

GKF-5B | 500 | 500×500×280 | 500×500×450 | 430×430×90 (Side gel sealing) | 200×200 |

GKF-10B | 1000 | 680×680×280 | 680×680×450 | 610×610×90 (Side gel sealing) | 200×320 |

GKF-15B | 1500 | 985×680×280 | 985×680×450 | 915×610×90 (Side gel sealing) | 200×400 |

GKF-20B | 2000 | 1290×680×280 | 1290×680×450 | 1220×610×90 (Side gel sealing) | 200×500 |

GKF-30B | 3000 | 1290×985×280 | 1290×985×450 | 1220×915×90 (Side gel sealing) | 200×600 |

Characteristics:

▷High efficiency filtration: HEPA box adopt HEPA or ULPA filter, the filtration efficiency is up to 99.99% or more, effectively removing particles and microorganisms in the air.

▷Uniform air supply: through the design of diffuser plate, it ensures uniform airflow distribution, avoids eddy flow, and maintains a stable environment in the clean area.

▷Low resistance design: optimise airflow channels, reduce wind resistance, reduce energy consumption and improve operation efficiency.

▷Easy maintenance: simple structure, easy filter replacement, reduce downtime, reduce maintenance costs.

▷Durable material: the housing is usually made of stainless steel or galvanised steel, which is corrosion-resistant, easy to clean, and suitable for clean environments.

▷Compliance with standards: meets GMP, ISO and other cleanroom standards to ensure compliance of the production environment.

▷Silent operation: reasonable design, low noise during operation, suitable for noise-sensitive environments.

▷Adjustable airflow: equipped with air valve, the airflow can be flexibly adjusted to adapt to different cleanliness requirements.

Applications:

HEPA box is widely used in industries with high cleanliness requirements, mainly including:

Pharmaceutical industry: used in clean workshops, aseptic production lines, etc., to ensure the cleanliness of the pharmaceutical production environment, in line with GMP requirements.

Electronics industry: used in semiconductors, integrated circuits and other precision manufacturing workshop, to prevent particulate contamination, to ensure product quality.

Medical and health care: used in operating theatres, aseptic wards, laboratories, etc., to control microorganisms and particles and ensure medical safety.

Food industry: used in clean production workshop to prevent microbial contamination and ensure food safety.

Biotechnology: used in biological laboratories, genetic engineering, etc., to provide a sterile environment and ensure experimental accuracy.

Aerospace: used in precision equipment manufacturing and assembly workshops to prevent particulate contamination and ensure product accuracy.

Optical industry: used in the production of lenses, displays and other precision optical components, to avoid dust affecting product quality.

![Applications Applications]()

SNYLI Production workshop:

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.

![SNYLI PRODUCTION WORKSHOP SNYLI PRODUCTION WORKSHOP]()

About us:

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, registered in Liaocheng City, Shandong Province, mainly engaged in air filtration products. Since the establishment of our company, we have been continuously deepening our research and development to improve our strength, and now we have mastered many patents and obtained ISO/CE certificates.

After more than ten years, SNYLI has set up branches in many places in China and a trading company in Jinan City, Shandong Province. At present, SNYLI products have been exported to both home and abroad, and we have signed long-term co-operation agreements with customers in many countries.

We always put the interests of customers in the first place, regularly follow up customer feedback, and strive to improve our own strength, and the constant pursuit of progress.

Giving us a chance to co-operate will be a decision that benefits both parties! SNYLI welcomes your enquiry!

![SNYLI FACTORY SNYLI FACTORY]()