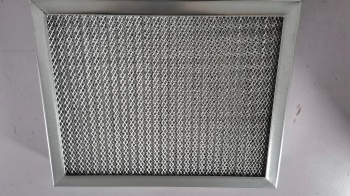

Metal Mesh Air Filters help Industrial Environmental Protection

In recent years, with the tightening of global environmental regulations and the rising demand for air purification in the industrial field, metal mesh air filters have ushered in a new round of growth in the application of HVAC, automobile manufacturing, chemical industry, food processing, and other industries by virtue of their durability, reusability, and ease of maintenance, demonstrating a strong potential for development.

Policy Driven: Environmental Protection Standards Upgrade, Market Demand Soars

Due to the restrictions on industrial emissions, the demand for energy-saving and environmentally friendly filtration equipment is growing dramatically. Metal mesh filters are more in line with the concept of sustainable development than traditional disposable filter media due to their washable, long-life and recyclable materials.

|  |

|  |

1. High strength and long life

The frame made of stainless steel, aluminum alloy, galvanized iron and other metal materials, has excellent resistance to pressure and corrosion, and can withstand high temperature, high humidity and strong airflow impact, with a life span of up to 5-10 years, which is far beyond that of paper or synthetic fiber filter materials.

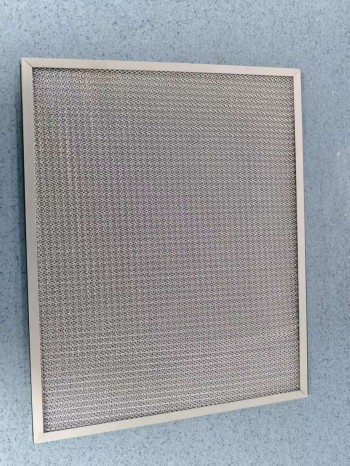

2. Repeatable cleaning, low maintenance cost

Support water washing, ultrasonic cleaning or compressed air blowback, no need for frequent replacement of the filter element, significantly reduce the cost of consumables (such as automotive painting line annual savings of more than 30% of the cost of filter media), especially suitable for high dust conditions (such as metallurgy, cement industry).

3. Low wind resistance, energy saving and high efficiency

The mesh structure reduces the initial pressure by 30%-50% compared with the traditional filter media, also reduces the energy consumption of the fan, and reduces the power consumption of the HVAC system by 15%-20% in long-term operation.

4. Environmental protection and sustainability

The metal material is 100% recyclable, avoiding the solid waste pollution of disposable cartridges and complying with EU RoHS and global carbon neutral policy.

5. Multi-functional adaptability

- High Temperature Resistance: Suitable for high temperature scenarios such as boiler exhaust and welding fume;

- Anti-static design: used in electronic workshop to avoid dust adsorption;

- Antimicrobial coating: to meet the hygiene standards of food and pharmaceutical industries.

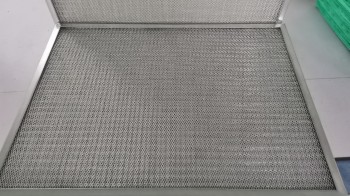

Various application scenarios

With its advantages of high durability, reusability, high temperature resistance and low wind resistance, metal mesh filters are widely used in high dust, high temperature or high humidity environments in several industries. The following are its main application places:

|  |

1. Industrial Manufacturing

- Automobile manufacturing: used in paint shop, welding fume filtration, intercepting paint mist and metal particles.

- Chemical industry: filtration of corrosive gases or dust (e.g. PVC, fertilizer production), acid and alkali corrosion resistance.

- Cement/metallurgical industry: handling high concentration of dust, such as sintering furnace, rotary kiln tail gas pretreatment.

2. Heating, ventilation and air conditioning (HVAC) and energy systems

- Commercial air conditioning: primary filtration of fresh air system in large shopping malls and office buildings to extend the life of subsequent filter elements.

- Data Center: Protect server room air conditioning equipment and reduce heat dissipation problems caused by dust accumulation.

- Gas turbine/boiler: Filter particles in intake air and prevent turbine blade wear.

3. Special environmental applications

- Commercial kitchens: pre-treatment of grease and fumes, reduce grease into the high-efficiency filter (easy-to-clean characteristics of significant advantages).

- Agriculture and Farming: Dust collection for grain processing, feed production, or filtration for livestock and poultry house ventilation.