Introduction:

Dust-laden air passes through the filter, trapping the dust within the fibre layer of the filter media. When the resistance of the fibre layer increases to the upper pressure difference value due to the condensation of dust, the automatic control system starts to activate the motor and replaces the clean filter material to keep the filter in the normal resistance state, thus ensuring the normal operation of the ventilation system.

Cold plate spraying, aluminium alloy profile, stainless steel can be used as the main material of the frame.

The whole adopts metal structure, which is solid and reliable, and can work normally in bad environment.

The photoelectric control adopts a large LCD screen to display the operation status, in situ sound and light alarm, timely reminder to replace the new filter material, and reserved remote alarm interface for remote control.

Modular assembly, intelligent filter media replacement system, can meet the requirements of complex airflow system, effective energy saving, reduce labour costs, more economical operation.

Auto Roll Air Filter is suitable for all kinds of ventilation and purification occasions, especially for the air purification effect of low-pressure and high-volume air supply system is particularly ideal.

![Auto Roll Air Filter Auto Roll Air Filter]()

Technical parameters:

Filtration efficiency grade: G3/G4-EN779

Wind speed: recommended less than 2.5m/s

Final resistance: recommended value 200-300Pa

Power: 100W

Power supply: 220V/380V-50Hz

Environmental air temperature: -10 ℃ to 40 ℃

Environmental relative humidity: 90%RH

How it works:

1. The new filter material is loaded in the loading box, when the high concentration of dusty air passes through the Auto Roll Air Filter, the pressure difference between the front and back of the filter rises gradually with the increase of filter dust.

2. When the filter resistance rises to the set final resistance value, the differential pressure switch starts to act.

3. After the controller receives the running signal, it immediately turns on the motor power and starts the motor automatically.

4. The motor running drives the reel in the lower material box to rotate, so as to roll up the dirty filter material, and at the same time the filter section is replaced with clean filter material.

5. The displacement of the filter material running by the grating for distance control, when the filter material running to the preset length in the controller, the controller will give the motor a signal to disconnect the power supply, the motor stops running.

6. Replacement of the filter media does not require personnel to go to the top of the machine, and can be replaced by the optional bracket chute with linkage.

Applications:

Water treatment plant blower inlet air filtration

Textile factory air conditioner return air filtration

Industrial ventilation for equipment cooling

Pre-filtration for central air-conditioning intake system

Sintering system purification in metallurgical industry

Pre-filtering of gas turbine air intake systems in power plants

Ventilation of equipment rooms or culverts on highways

Ventilation of metro and human defence works

Ventilation of large air volume in pits in the coal industry

Environments with high dust content and frequent replacement of filter media;

Operation systems with constant air volume.

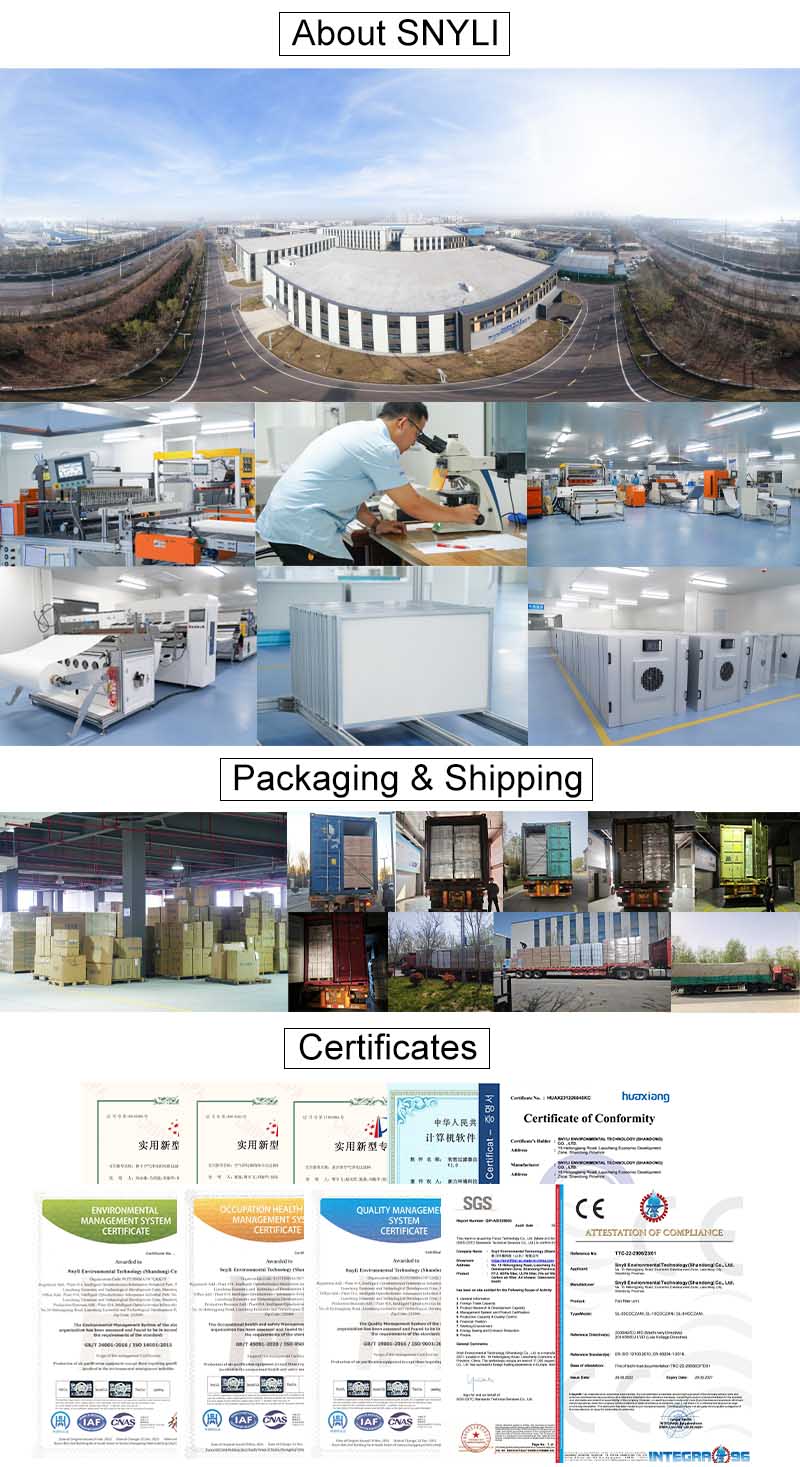

About us:

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()