Introduction:

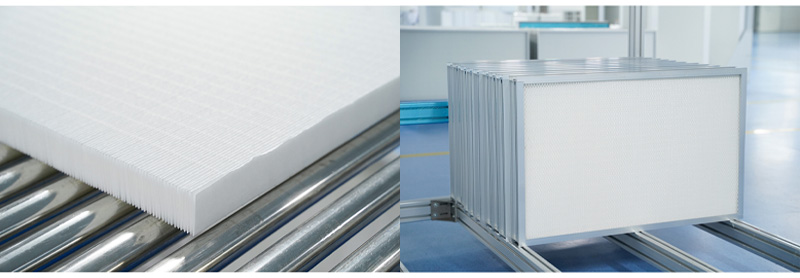

Mini Pleat ULPA Air Filters, which can effectively reduce the operating costs of cleanrooms, have passed effective leakage detection and scanning tests before leaving the factory, and can meet the specific requirements of special industries, and are applicable to a variety of cleanrooms, clean benches, pharmaceutical factories, biological factories, food processing, and other places where air pollution control is required.

Efficiency: According to the European standard EN1822 test, i.e. test the particle concentration in the upwind and downwind of the filter, the efficiency of HEPA grade is from 95~99.999% through 0.3um, and the efficiency of ULPA grade is from 99.999~99.999999% through 0.1~0.2um.

Filter Material: The filter material consists of ultra-fine glass fibers assembled into a frame after pleating, and the filter paper is spaced by hot-melt adhesive, which will not release chemical contamination into the clean room, and enable the air to pass through the filter with the lowest pressure loss.

Outer frame: The inner side of the outer frame is sealed with sealant around the perimeter to prevent gaps between the filter media and the filter or problems with filter leakage. Aluminum frame is anodized to increase hardness and durable corrosion resistance. The aluminum frame is sealed with PU adhesive to achieve complete airtightness and no leakage.

![Mini Pleat ULPA Air Filter Mini Pleat ULPA Air Filter]()

EN1822 standard MPPS efficiency

| 99.95%@0.3μm (H13) |

| 99.995%@0.3μm (H14) |

| 99.9995%@0.12μm (U15) |

| 99.99995%@0.12μm (U16) |

| 99.999995%@0.12μm (U17) |

Characteristics:

Frame: Anodized aluminum

Media: Glass fiber

Efficiency:

U15 (EN 1822)/MERV 20 (ASHRAE 52.2)

MPPS: ≥99.9995% / DOP: ≥99.9999%@0.12 μm

U16 (EN 1822)/MERV 20 (ASHRAE 52.2)

MPPS: ≥99.99995% / DOP: ≥99.99999%@0.12 μm

Separator: Hot melt

Gasket: EPDM

Max. Temperature: ≦ 70°C

Max. Humidity: ≦ 100% RH

Structural description:

Unique seamless sealing technology, good sealing effect, not easy to leak.

Small volume and light weight. Adopting anodized aluminium alloy outer frame material, easy to carry and install.

Available in 50mm, 70mm, 90mm and many other thicknesses.

Installation Instructions:

Can be installed on the ceiling keel or on the colour steel plate ceiling with FFU.

ULPA Air filters need to be installed after the air duct is installed, test blowing of the room, and after the air volume and indoor cleanliness have reached certain requirements, in order to extend the service life of high-efficiency filters.

In order to ensure the service life of the ULPA filter, it is recommended that a pre-filter of not less than F8 filtration grade be installed at the front end of this filter stage.

Common dimensions:

Size

W×H×D(mm) | Air Flow

(m3/h) | U15 Initial P.D. (Pa) | Recommended Final P.D. (Pa) | MPPS efficiency |

610×610×70 | 600 | 150 | 450 | ≥99.9995%@0.12μm |

1170×570×70 | 1100 |

1170×870×70 | 1700 |

1170×1170×70 | 2200 |

610×610×90 | 750 |

1170×570×90 | 1300 |

1170×870×90 | 1950 |

1170×1170×90 | 2600 |

Applications:

Mini Pleat ULPA Air Filters can meet the stringent requirements of today's air purification for various space, weight and energy consumption.

With high efficiency, low resistance and large dust capacity, the Mini Pleat ULPA Air Filter is widely used in industrial clean rooms of semiconductors, electronics, flat panel displays, precision machinery, surface coating, aerospace and other industries to ensure the normal operation of the production process and improve the yield rate.

Used in pharmaceutical, medical, food and beverage, biological engineering, laboratory animal breeding and other biological clean room, to create a sterile environment.

![Applications Applications]()

About us:

Founded in 2010, Snyli Environmental Technology (Shandong) Co.,Ltd is a high-tech enterprise focusing on the research, development, production and sales of air filtration products, with its headquarter and R&D base located in Liaocheng City, Shandong Province, which is a beautiful city with beautiful scenery, and has branch offices all over China.

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()

Main products: primary efficiency air filters, medium efficiency air filters, hepa ulpa air filters, pocket air filters, v bank air filters, mini pleat hepa air filters, deep pleat air filters, box type v cell air filters, rigid bag air filters, high temp resistant air filters, fan filter units, auto roll air filters, activated carbon air filters, clean bench, clean booth, air shower, pass box.

![SNYLI Main products SNYLI Main products]()

Packaging & Shipping:

Adopt export standard packaging - cardboard box or fumigation-free wooden box or three-plywood wooden box.

International express delivery, sea freight, air transport, railway transport and other modes.

![Packaging & Shipping Packaging & Shipping]()

Certificates:

SNYLI has strong R&D strength and rich production experience, and has obtained many patents and ISO/CE certificates, SNYLI's R&D and production products are gradually gaining more and more recognition from customers.

![SNYLI Certificates SNYLI Certificates]()

Why choose us:

Provide samples for customers to test, provide perfect after-sales service for customers to solve the worries.

Accept product customisation, and experienced in customisation, technical staff can assist in providing advice.

Own factory, short production cycle, quality is guaranteed.