Semiconductor industry air filters

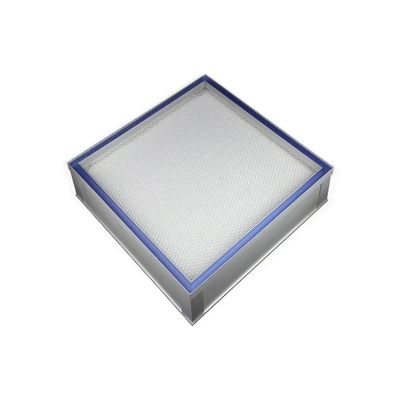

Dust sticking to integrated circuits can cause disconnection and short circuits, and dust directly affects product yield. Today, the semiconductor industry (chip factories) is the most demanding in terms of air cleanliness in production environments, and also has the strictest requirements for air filters.

The traditional form of ventilation in a chip factory is the ‘’large circulation‘’, in which the whole ceiling of the workshop is covered with HEPA filters, and the whole floor is a return air grille. Nowadays, some workshops in chip factories use FFUs (‘’Fan Filter Units‘’), which are equipped with their own fans, and both types of large circulation and FFUs are able to achieve sufficient cleanliness, with only some differences in operation management and energy consumption.

Both HEPA filters and FFUs are scanned and tested unit by unit before leaving the factory.

Airborne sea salt particles are the archenemy of all electronics industries, but airborne sea salt dust has relatively large particles that can be filtered out by ordinary filters. The coastal areas are economically developed and some electronics industries choose to locate their plants there, which requires a little more money to be spent on filters.

Today's filtration technology can reduce the dust concentration in a cleanroom to nearly zero, as clean as you want it to be. When the line width on a chip is as small as 0.5μm, chemical contaminants in the air become a major hazard to yield. As a result, chemical filters are commonly required in the air conditioning systems of chip factories with line widths less than 0.5μm. The principle and manufacturing process of chemical filters is not complicated, it is the activated carbon filter.

Sources of chemical contaminants may be: outdoor air, the process itself, people, and decoration materials. In most cases, designers and site personnel cannot say what the pollutant types and concentrations are. Therefore, the chemical filters used should have at least two characteristics: broad-spectrum adsorption properties and a sufficient amount of activated carbon material. Broad-spectrum adsorption means that it can adsorb anything, and the material that can have this function is the most common and cheapest granular activated carbon. If the type of pollutant can be identified, the activated carbon material can be subjected to targeted chemical treatment to enhance the adsorption capacity for specific pollutants.

The semiconductor industry is not a ‘smokeless industry’ as is commonly believed, and it also has environmental problems. Because the latest processes and materials are often used, some chemicals are used in large quantities before their safety has been assessed, and the slightest carelessness can lead to serious chemical pollution, both of groundwater and air. For safety reasons, some companies also use chemical filters in their exhaust air systems.