Introduction:

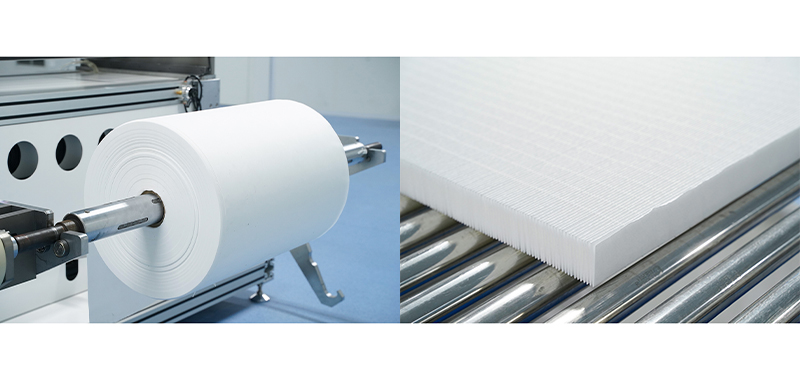

PTFE Air Filter Media is a kind of product made of PTFE as raw material, through a special process, bi-directional stretching, taking advantage of the unique node protofibrillar nature of polytetrafluoroethylene film, smooth surface, chemical substance resistance, breathable and impermeable to water, high air permeability, flame retardant, high temperature resistance, resistance to strong acids and alkalis, non-toxicity and other characteristics. Because of its excellent quality, it is widely used in high-efficiency air filters.

![PTFE Air Filter Media PTFE Air Filter Media]()

Common dimensions:

Width mm | Weight g/m2 | Thickness mm | Pressure Drop Pa@5.3cm/s | Filtration Efficiency % | Size Range um | Filter Grade |

1850 | 80 | 0.3-0.4 | 100-140 | ≥99.95 | 0.3-0.5 | H13 |

1850 | 80 | 0.3-0.4 | 140-190 | ≥99.995 | 0.3-0.5 | H14 |

1850 | 80 | 0.3-0.4 | 190-240 | ≥99.999 | 0.1-0.2 | U15 |

1850 | 80 | 0.3-0.4 | 240-290 | ≥99.9999 | 0.1-0.2 | U16 |

Features:

1.High temperature resistance

PTFE Air Filter Media has good high temperature resistance and can operate normally under extreme temperatures.

2. Excellent chemical stability

PTFE Air Filter Media surface has very high chemical inertness. It can withstand a variety of chemicals, can operate normally in acid, alkali and other heavy corrosive media.

3. Anti-static

PTFE Air Filter Media has good anti-static properties, can effectively absorb static electricity, to avoid the impact of static electricity on the filtration system and the filtered material.

4. Strong air permeability

PTFE Air Filter Media has good air permeability, which can achieve good filtration effect.

5. Good flame resistance

PTFE Air Filter Media is flame retardant and will not release harmful gases even at high temperatures.

Applications:

PTFE air filter material is mostly used in high-efficiency air filtration, which has high filtration efficiency, good filtration effect, low resistance, low energy consumption, and good effect of trapping dust and bacteria. In general, it can be used for about two years, but the specific time needs to be determined by the use of the environment.

Widely used in semiconductor, electronics, precision manufacturing, bio-pharmaceutical and other industries.

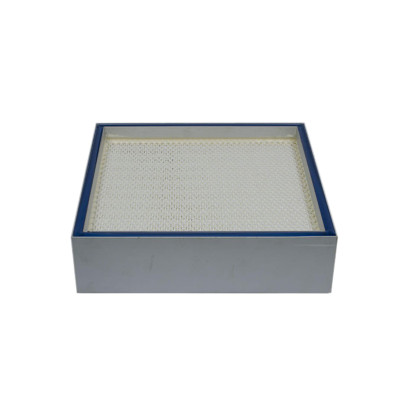

About us:

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()