Service life of terminal HEPA filters

For an operating cleanroom, the value of the terminal HEPA filter is not high - it may be less than two hours' worth of user output, but the risk and overheads of replacing the filter can be high.

The most fundamental way to extend the life of HEPA filters is to keep dust out of the pre-filter. Replacing the pre-filter generally requires no downtime and no commissioning, and will significantly reduce risk and expense.

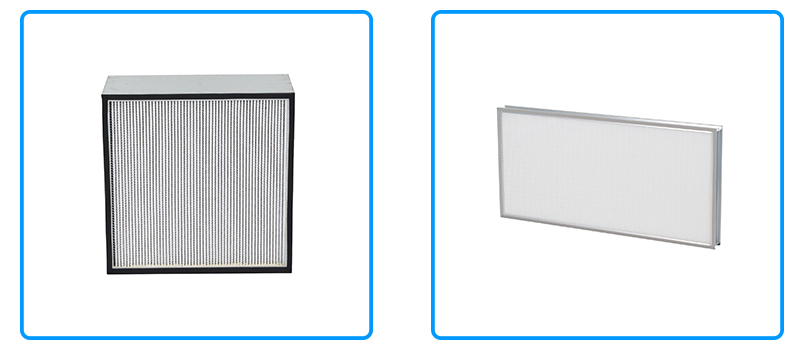

|  |

|  |

For class 10,000 (ISO7) and class 100,000 (ISO8) clean rooms, the pre-filter can be F8 air filter. In this way, the service life of the end HEPA filter is generally up to 5 years. F8 air filters are the most common pre-filters used in non-uniform flow cleanrooms in projects around the world.

For clean rooms in chip factories of class 100 (ISO5), class 10 (ISO4) or higher, the common efficiency class for pre-filters is H10, and many new-plant projects go straight to using HEPA.

There are occasions when the regulations on the service life of HEPA filters are not motivated by considerations of resistance, but by other factors. If there is hydrofluoric acid in the plant and the shop air conditioning is not a full fresh air system, the glass fibre filter paper in the HEPA filters will be corroded by the return air and the HEPA filters must be replaced periodically for safety reasons. In some pharmaceutical plants, the HEPA filters are changed every year after the rainy season, in order to prevent any possible mould contamination on the filters. Some biological laboratories and laboratories that work with hazardous materials, before starting a new and important project, will use new HEPA filters in order to be reliable.