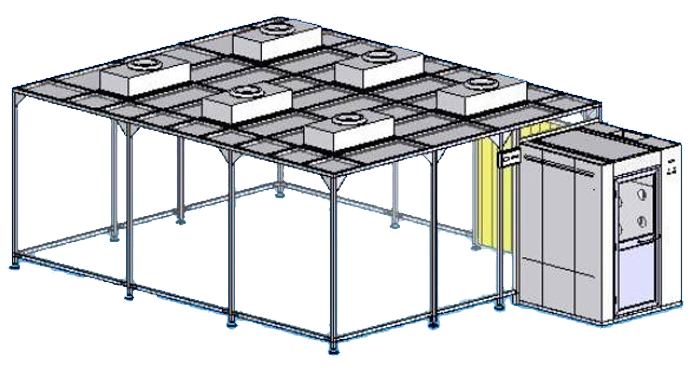

Take a comprehensive view of the Clean Booth

As the level of industrial production improves, the air cleanliness requirements of various industries are getting higher and higher, and if the whole clean room is built according to the required cleanliness, then the cost will be higher. In order to reduce costs, while achieving the requirements of the production environment, this local purification equipment--clean booths came into being.

I.Clean booth working principle

Class 10-100 clean booth: To make the indoor purification level reach class 100 or above, it is necessary to make the indoor clean airflow form a unidirectional vertical flow. That is to say, the airflow in the clean room in the same cross-section of any point of the airflow direction and speed to maintain the same, so that the clean airflow as a piston to take away the dust particles indoors at the fastest speed. In order to achieve vertical flow, it is necessary to cover the roof with HEPA filters to realise one-way vertical flow and achieve a cleanliness level of Class 100 or above.

1K-100K clean booth: the direction of its airflow organisation is different from that of Class10-100 clean booth, the internal airflow is at an uneven speed with non-parallel flow, accompanied by reflux and vortex, which mainly relies on the clean airflow to continuously dilute the internal air, and gradually discharges the internal contamination to realise the clean effect. To realise the different levels of the clean booth, it is mainly dependent on the difference in the amount of air sent per unit of time.

II. Material of clean booth

Clean booth is mainly composed of box, fan, primary air filter, damping layer, lamps and so on, and the shell is sprayed with plastic. The product can be both hanging and ground support.

1. Bracket: special aluminium profile, iron square or stainless steel square.

2. Anti-static curtains: 0.3mm thick mesh, good anti-static effect, high transparency, clear mesh, soft, good toughness, no deformation, not easy to aging: insulation, dust removal and good static electricity performance.

3. Anti-static plexiglass plate: good anti-static effect, high transparency, not easy to aging, suitable for high demand occasions.

4. Top sealing board of the clean booth: the purification blind board can adopt 0.3mm anti-static curtain, 1.0mm aluminium board or cold board baking paint.

5. Purification lighting system can be adopted in the clean booth.

6. Fan filter air supply unit FFU: adopts low-noise centrifugal fan with long life, low noise, maintenance-free, small vibration and adjustable speed. The HEPA (high efficiency filter) is set at the end of the fan air supply unit, and the HEPA has the features of small initial resistance, large dust capacity, high filtration efficiency, long service life and easy to replace, etc.

III. Clean booth purification level

Most of the clean room built into class 10,000, choose class 1,000 clean booth, or class 100 clean booth, a small number of customers will choose class 10. In short, the clean booth level of choice according to the customer's need for cleanliness, but because of the clean booth is more confined, if the choice of clean booth level is relatively low, it will often bring part of the side effects: insufficient cold, employees in the clean booth will feel more hot and stuffy.

IV.The relationship between clean rooms and clean booths

Generally speaking, the clean booth is built inside the clean room, the main role is to make the local air purification level increase.

When the clean booth is not built in the clean room, due to the lack of primary air filters, medium-effect filters to protect the clean booth, the service life of the HEPA filters inside the clean booth will be shortened accordingly compared to the HEPA filters in the clean room, and the long-term use cost is higher.

However, if the clean booth is built in the clean room, because of the clean room air conditioning system and air shower room, transfer window and other purification equipment protection, clean booth service life will be extended, in favour of sustained production and the stability of the yield rate.

SNYLI is a professional air purification products service provider in China, with its own factory in Liaocheng City, Shandong Province, we can provide you with various specifications of air filters and various air purification products!