Introduction:

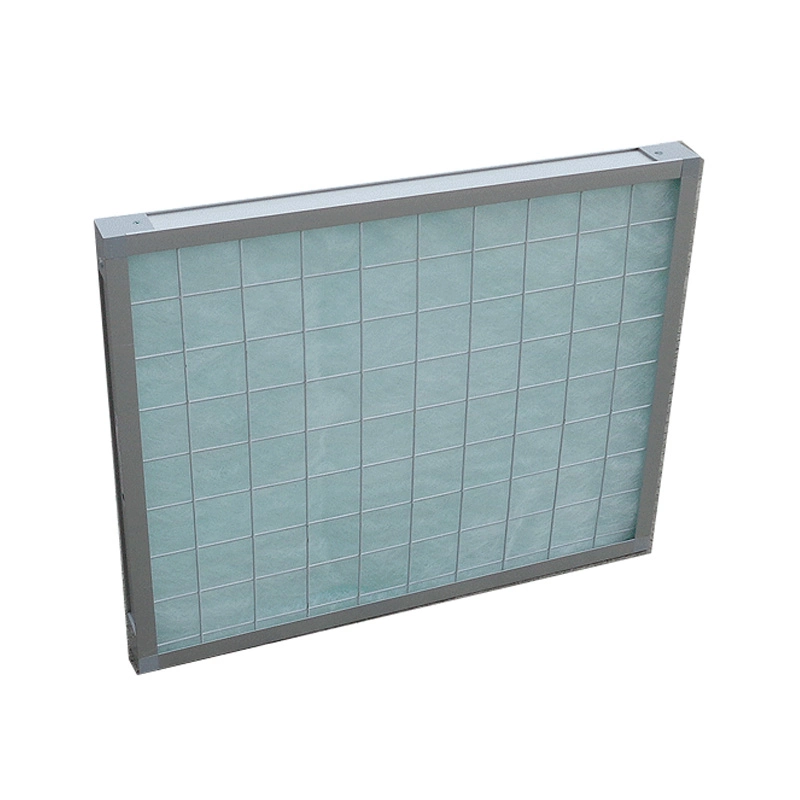

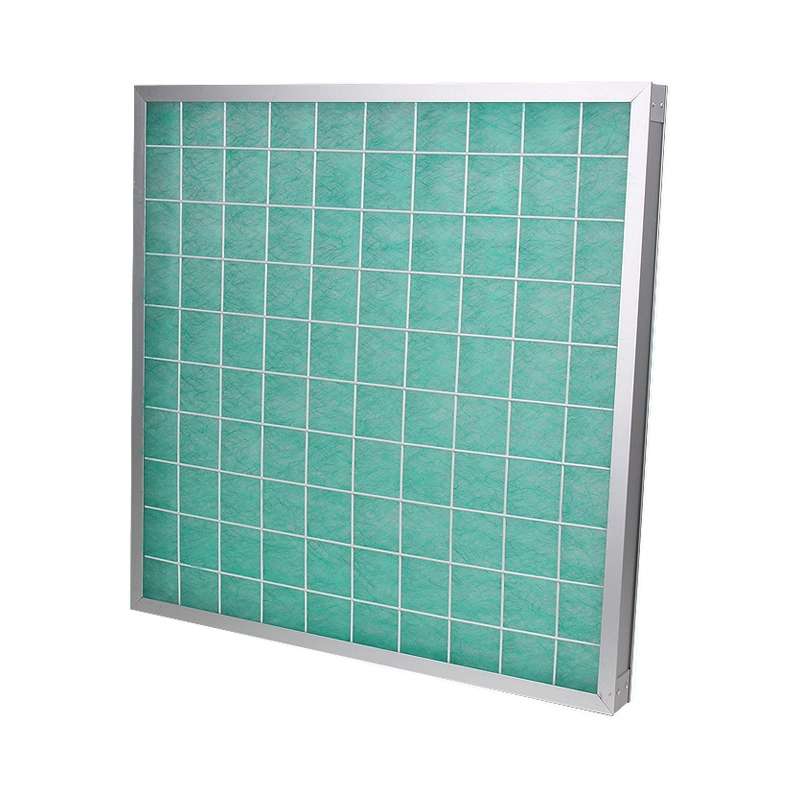

Paint Booth Pre Filter uses glass fibre as the filter media, which has a variety of excellent properties and is particularly suitable for environments that require high temperature treatment and high efficiency air purification.

1.Material:

Glass Fibre: The filter media is glass fibre, which is a material consisting of thin and long glass fibre filaments with good heat resistance and chemical stability.

2.Structure:

| Frame material | Cardboard, Aluminium or galvanised frame |

|---|

| Filter material | Made of highly elastic, fracture-resistant glass fibre with an increasing fibre structure. |

|---|

| Efficiency | G3,G4,M5 |

|---|

| Temperature resistance | 170℃ |

|---|

| Max. Relative Humidity | 100% RH |

|---|

| Applications | Pre-filtration for air conditioning and painting systems, paint spraying systems and workshops |

|---|

![Paint Booth Pre Filter Paint Booth Pre Filter]()

3.Common size:

External Dimensions (mm) | Rated air volume (m3/h) | Initial pressure loss (Pa) |

290*595*46 | 3400 | 135 |

490*595*46 | 2000 | 135 |

595*595*46 | 1500 | 85 |

4.Performance Characteristics

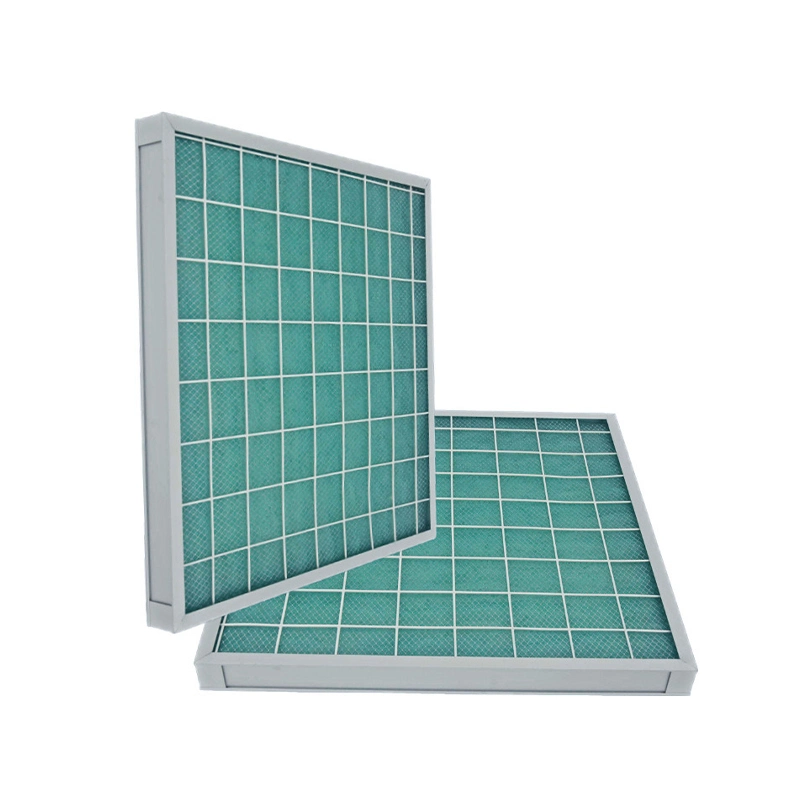

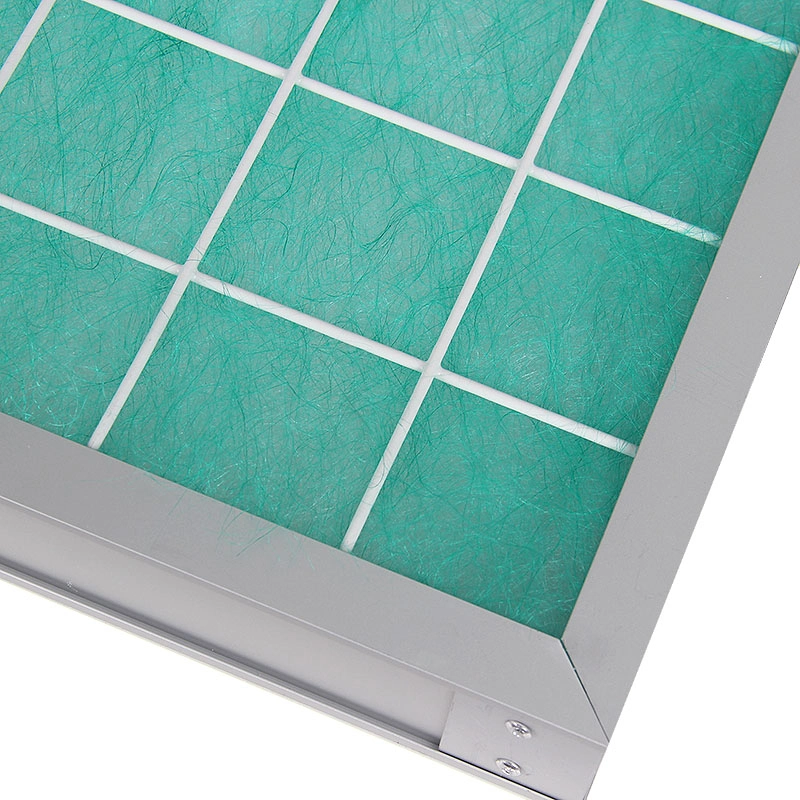

High temperature resistance: generally can withstand working temperatures of up to 170 degrees Celsius, suitable for paint spray booths and other high temperature environments.

Thermal stability: it will not melt, deform or degrade under high temperature, maintaining its structural integrity and filtration efficiency.

Efficient filtration performance: glass fibre has a fine fibre diameter and high density structure, which can effectively capture dust, particles and other impurities in the air.

Chemical stability: corrosion resistance, good resistance to most chemicals, not easily affected by chemicals. It can still maintain its performance after long time use in chemical environment and reduce the damage caused by chemical corrosion.

5. Areas of application

Paint spray booth: high temperature spraying. Suitable for paint spray booths that require high temperature spraying, such as automobile manufacturing, furniture painting and other industries.

Drying process: in the drying process after spraying paint, it can also effectively remove impurities in the air to ensure the quality of coating.

Other industrial applications:

Paint booth: used for air purification in paint booths to ensure the quality of baking paint.

Drying equipment: applicable to a variety of drying equipment, such as food processing, textile drying and so on.

Industrial Furnaces and Kilns: can be used for air purification in industrial furnaces and kilns to protect the equipment and workers' health.

![Paint Booth Pre Filter Paint Booth Pre Filter]()

6. Summary of advantages

High temperature resistance: able to work stably in environments up to 170 degrees Celsius.

High efficiency filtration: good particle capture ability and high filtration efficiency.

Chemical stability: good resistance to chemicals, suitable for a wide range of industrial environments.

Long service life: long service life, reducing the need for frequent replacement.

Low resistance: designed with low resistance characteristics in mind, improving the energy efficiency of the system.

Environmentally friendly: non-toxic, harmless, and friendly to humans and the environment.

Easy to install and maintain.

7. Cautions

Temperature limitation: Although resistant to high temperatures, exceeding its maximum working temperature should be avoided.

Regular inspection: Check the condition of the filter regularly and replace it in time to ensure optimal performance.

Environmental adaptability: Select the model and specification suitable for the specific application scenario to obtain the best results.

About SNYLI:

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, registered in Liaocheng City, Shandong Province, mainly engaged in air filtration products. Since the establishment of our company, we have been continuously deepening our research and development to improve our strength, and now we have mastered many patents and obtained ISO/CE certificates.

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.

![SNYLI Production Workshop SNYLI Production Workshop]()

After more than ten years, SNYLI has set up branches in many places in China and a trading company in Jinan City, Shandong Province. At present, SNYLI products have been exported to both home and abroad, and we have signed long-term co-operation agreements with customers in many countries.

We always put the interests of customers in the first place, regularly follow up customer feedback, and strive to improve our own strength, and the constant pursuit of progress.

Giving us a chance to co-operate will be a decision that benefits both parties! SNYLI welcomes your enquiry!

![SNYLI FACTORY SNYLI FACTORY]()