Introduction:

Activated carbon bag filter is a kind of air purification equipment which combines bag filter technology and activated carbon adsorption technology. It has a wide range of applications in both industrial and civil fields, mainly used to remove particulate matter, odor and some harmful gases in the air.

1. Structure

Activated carbon bag filters usually consist of the following main parts:

Frame: usually made of metal or plastic, that supports the entire filter.

Filter bag: composed of synthetic fiber and activated carbon material.

| Frame | Aluminium/Galvanized |

|---|

| Media | Polyester + active carbon |

|---|

| Sealant | Polyurethane |

|---|

| Max. Temperature | 70℃ Max. |

|---|

| Max. Relative Humidity | 95% RH Rec. |

|---|

![Activated Carbon Bag Filter Activated Carbon Bag Filter]()

2. How it works

Activated carbon adsorption: Air passes through the activated carbon layer, and activated carbon removes volatile organic compounds (VOCs), odors and other harmful gases from the air through physical adsorption.

3. Common dimensions:

Dimension (mm) | Rated airflow (m³/h) | Efficiency | Initial resistance |

592*592*381-6P | 3600 | G4 | ≤85Pa |

290*592*381-3P | 1500 |

490*592*381-5P | 3200 |

490*490*381-5P | 2800 |

Note: The air volume is different under different wind speeds. Special sizes and specifications can be made according to customer requirements. |

4. Performance characteristics:

Comprehensive purification. It can not only remove particles, but also effectively remove odors and harmful gases, providing a comprehensive air purification solution.

Particulate matter filtration. It can remove dust, pollen, PM2.5 and other fine particles in the air.

Strong adsorption capacity. Activated carbon can effectively absorb volatile organic compounds (VOCs), odors, smoke and other harmful gases in the air.

Through reasonable filter bag design, activated carbon bag filter can reduce wind resistance and energy consumption while maintaining efficient filtration.

Low wind resistance design, suitable for various ventilation systems, reduce the energy consumption of the fan, reduce the operating cost.

Filter bags are usually made of durable synthetic fiber materials with good mechanical strength and durability.

Diverse applications. Suitable for home, office, hospital, laboratory, industrial sites and other environments.

Customizable. Different specifications and models of filters can be selected according to specific needs to meet the air purification requirements of specific occasions.

No secondary pollution. Activated carbon adsorption is a physical process that does not produce new harmful substances and is environmentally friendly.

Not harmful to humans. Activated carbon itself is safe, does not release harmful substances, and is suitable for long-term use.

Check regularly. The state of the filter can be assessed by visual inspection and simple testing.

Easy to change. Simple replacement operation.

5. Application field

Activated carbon bag filters are widely used in the following fields:

Home: Used to improve indoor air quality, remove odors and harmful gases.

Office: Improve the comfort of the office environment and reduce the discomfort caused by poor air quality.

Hospital: Keep the healthcare environment clean to reduce the risk of cross infection.

Laboratory: Ensure the purity of the air in the laboratory to avoid the influence of pollution on the experimental results.

Industrial sites: Such as chemical plants, pharmaceutical factories, etc., used to remove harmful gases and odors generated in the production process.

Catering industry: Remove kitchen fumes and odors, improve the quality of the dining environment.

![Application Application]()

6. Maintenance methods

Regular inspection: Check the appearance and performance of the filter regularly to ensure that it is working properly.

Record maintenance logs: Record the time and content of each maintenance to track filter usage and performance changes.

Regular replacement: According to the manufacturer's recommended replacement cycle and actual use, replace the new filter in time to maintain a good filtering effect.

Activated carbon bag filters have significant advantages in terms of air purification. Proper selection and maintenance of filters can effectively improve air quality and ensure people's health and comfort.

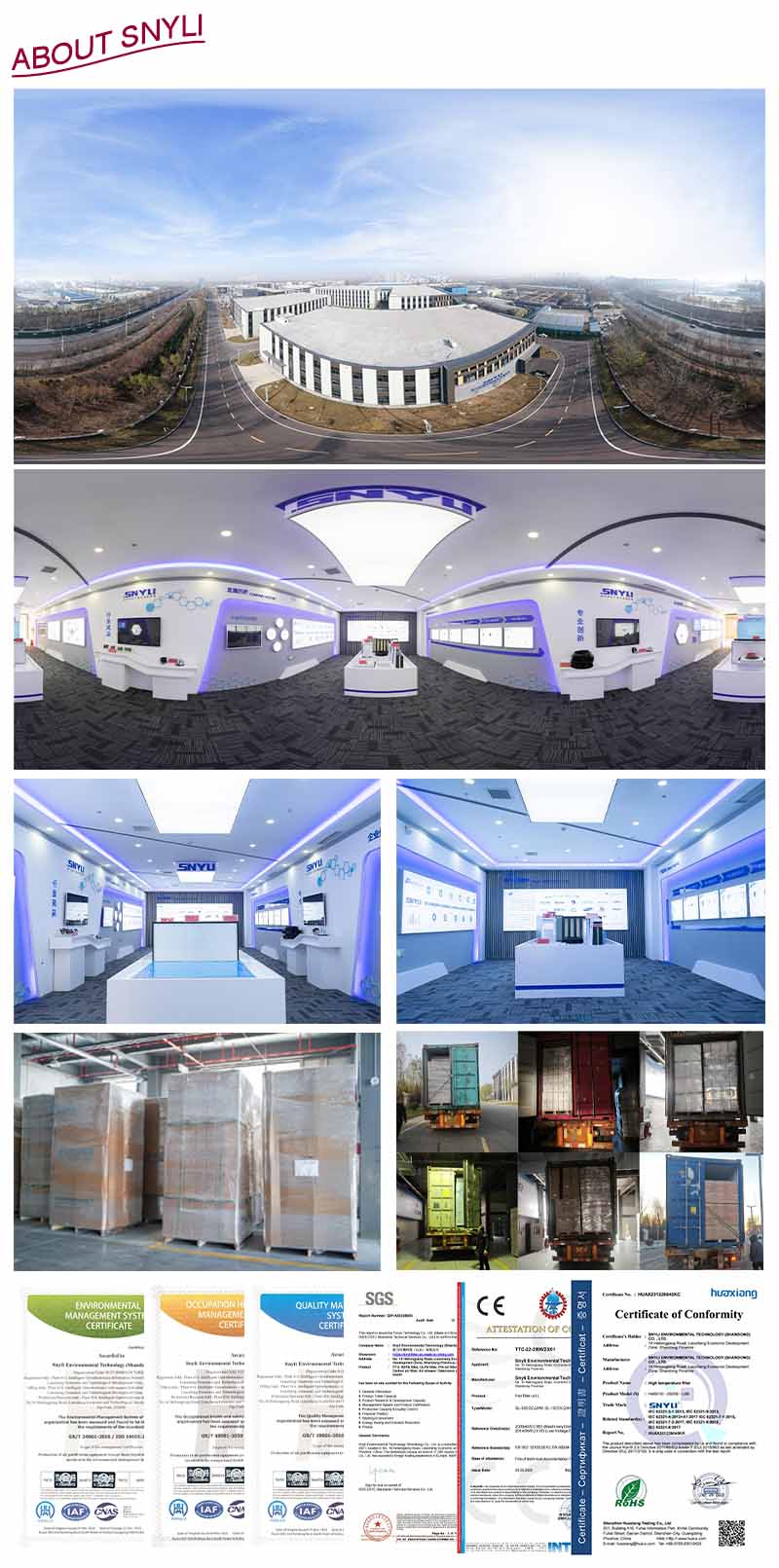

About us:

Snyli Environmental Technology (Shandong) Co., Ltd has the strength and experience in R&D and production to provide a wide range of air filtration products to our customers. Since SNYLI has been engaged in foreign trade export, we have been constantly praised by customers from various countries, and we are always proud of the quality products we have provided to our customers. In the future, we will always keep our original intention, continue to develop and innovate, and provide even better products and services to customers from all over the world.

![SNYLI PRODUCTION WORKSHOP SNYLI PRODUCTION WORKSHOP]()

With more than 20,000 square metres of production base, the annual production capacity is in millions. Automated clean production workshop, independent warehouse, guaranteed delivery. With professional technical team, more than ten years of industry experience, in-depth application expansion.

Strictly in accordance with ISO9001:2015 quality system standards, the introduction of advanced dust particle counters and other inspection and processing equipment to ensure product quality, qualified before being allowed to leave the factory.

Professional sales staff to match the demand, after-sales timely follow-up of customer use. Any problems encountered during the use of the product can be put forward to us at any time. Regular tracking of customers, so that customers get a good purchasing experience.

![SNYLI FACTORY SNYLI FACTORY]()