Introduction:

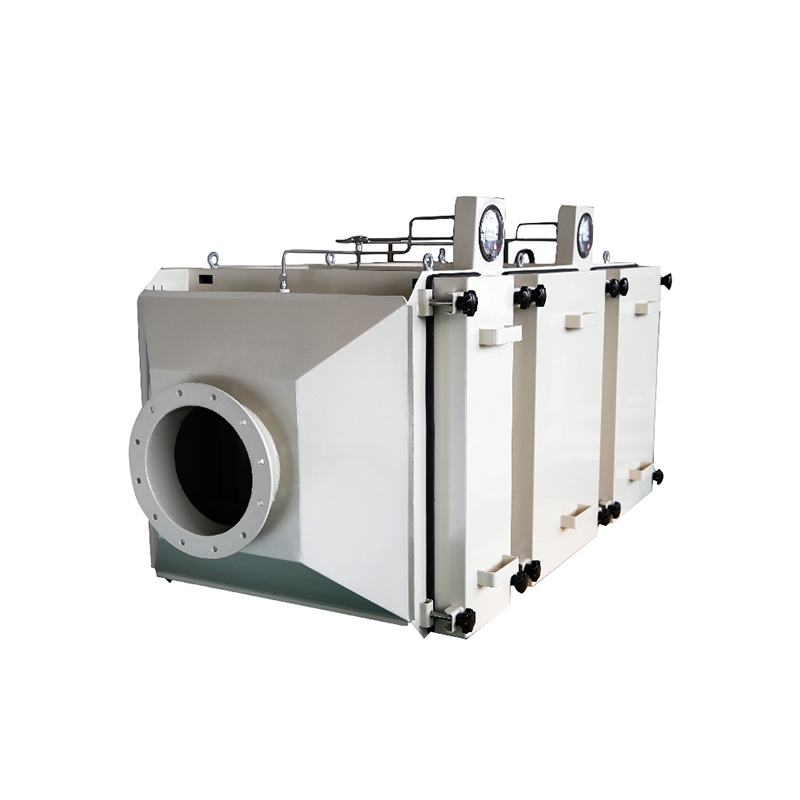

Bag in bag out filters (‘BIBO’) are a type of safety protection filtration system that is typically connected to an exhaust system to prevent the escape of hazardous contaminants. It provides a safe and reliable replacement method for air filters or chemical filters used in hazardous environments. Filter replacement takes place in a protective bag that prevents the gas inside the box from coming into contact with the outside world, thus protecting the operator and the environment. The protective bag is also equipped with gloves to facilitate the replacement operation.

![Bag in bag out Bag in bag out]()

The bag-in bag-out filter is a commonly used exhaust device in the pharmaceutical industry and biosafety laboratories. It adopts the fully closed bag-in bag-out design, which can effectively isolate radioactive gases, pathogens and chemical contamination. The housing can effectively prevent secondary air pollution and ensure the safety of operators.

Parameters:

Model | SS-B1 | SS-B2 | SS-B3 |

External dimensions (H*W*D) | 708*453*532 27.9″*17.9″*21.0″ | 708*708*794 27.9″*27.9″*31.3″ | 1416*1416*1694 55.8″*55.8″*66.8″ |

Maximum airflow | 1700m³/h 1000CFM | 3400m³/h 2000CFM | 13600m³/h 8000CFM |

HEPA filter section | 99.99%@0.3μm | 99.99%@0.3μm | 99.99%@0.3μm |

H14@EN1822 | H14@EN1822 | H14@EN1822 |

610*305*292mm-1PCS | 610*610*292mm-1PCS | 610*610*292mm-4PCS |

Coarse filter section | - | G4@EN779 | G4@EN779 |

Chemical filter section | - | - | VOC/Acid/Alkali |

Main Material | Steel plate with plastic spraying/SUS304 stainless steel |

PAO sampling port | SUS304,φ10mm |

Differential pressure gauge | Optional accessory, 0-500 Pa |

Pipeline micro-efficiency | Optional accessory |

Bioseal valve | Optional accessory |

Sterilisation port | Optional accessory |

High efficiency PAO scanning system | Optional manual/automatic Scanning mechanism |

Net weight | 41kg | 72kg | 362kg |

Gross Weight | 52kg | 86kg | 416kg |

Performance characteristics:

In general, the bag-in-bag-out filter consists of two parts, the filter unit and detection unit, the simplest filter unit contains only HEPA filter, if the air does not have other filtration equipment before entering the bag-in-bag-out filter, it is necessary to configure a pre-filter to protect the HEPA filter, and if there are adsorption requirements for the filtered gas, it will be equipped with a high-efficiency gas adsorption filter; the detection unit refers to the automatic (or manual) fine scanning device.

The biggest feature of the bag-in-bag-out filter is that when installing, replacing and testing the filter, it is all carried out under the protection of PVC bag (or high-temperature bag), and the filtration unit does not come into contact with the outside air, which ensures the safety of the personnel and the environment, and makes the replacement process convenient and quick.

Applications:

Widely used in a variety of areas with high hazard or isolation requirements, such as: chemical and biological (CB) containment, chemical, biological and radiological (C B R ) containment, nuclear chemical, biological and chemical (NBC) containment, hospital isolation rooms, pharmaceutical facilities, microelectronic environments, food processing areas, biological research, genetic and biotechnology laboratories, industrial treatment discharge systems, chemical treatment facilities, animal disease research laboratories, radioisotope processing facilities, nuclear power stations, strategic nuclear facilities, D.O.E. facilities, military bases, etc.

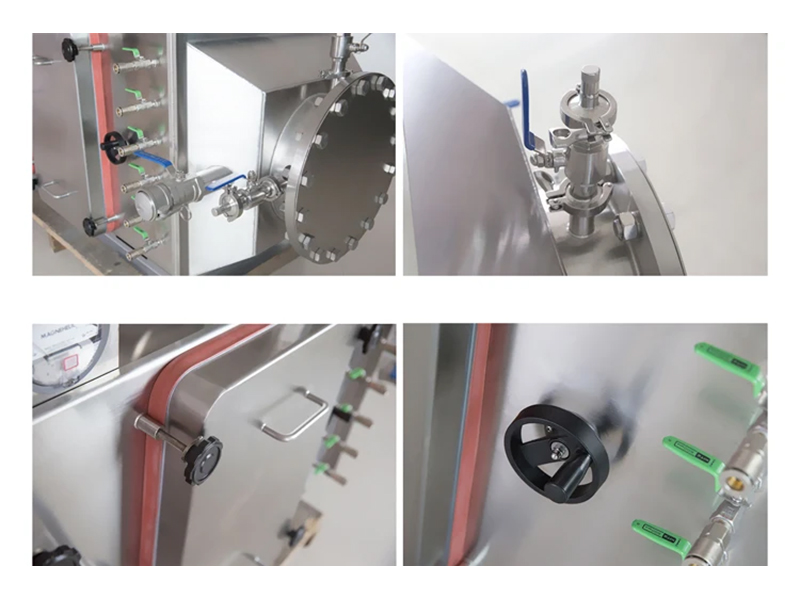

SNYLI Production workshop:

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.

![SNYLI Production workshop SNYLI Production workshop]()

About us:

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, registered in Liaocheng City, Shandong Province, mainly engaged in air filtration products. Since the establishment of our company, we have been continuously deepening our research and development to improve our strength, and now we have mastered many patents and obtained ISO/CE certificates.

After more than ten years, SNYLI has set up branches in many places in China and a trading company in Jinan City, Shandong Province. At present, SNYLI products have been exported to both home and abroad, and we have signed long-term co-operation agreements with customers in many countries.

We always put the interests of customers in the first place, regularly follow up customer feedback, and strive to improve our own strength, and the constant pursuit of progress.

Giving us a chance to co-operate will be a decision that benefits both parties! SNYLI welcomes your enquiry!

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()