Introduction:

Clean bench is a kind of equipment that uses air cleaning technology to provide a sterile operating environment for the laboratory. It purifies the air through a high-efficiency air filter (HEPA), so that the air inside the bench reaches a certain level of cleanliness. Staff conducting experimental operations on the ultra-clean bench can effectively reduce experimental contamination and ensure the reliability of experimental results.

![Laminar Flow Clean Bench Laminar Flow Clean Bench]()

Common dimensions:

Cleanliness | Laminar flow type | Air velocity | Noise | Power supply | External dimensions (W×D×H) | Woking area (W×D×H) |

Class 100 | Horizontal | 0.45~0.75 m/s | ≈50dB | AC,1φ -220V/50HZ | 1250×650×1750 | 1000×800×1450 |

Vertical | 1170×600×800 | 960×600×600 |

Features:

High air cleanliness: Adoption of HEPA filter can effectively filter bacteria, viruses, dust and other pollutants in the air, so that the air inside the workbench reaches a high degree of cleanliness.

Anti-pollution design: Fully enclosed design to avoid external pollutants entering the work area. At the same time, the surface of the bench is smooth and easy to clean and disinfect.

Easy to operate: Clean bench is generally equipped with lighting, power, gas and other interfaces to facilitate experimental personnel to carry out experimental operations.

Flexibility: The size of the ultra-clean bench is varied and can be selected according to the size of the laboratory space and experimental needs.

Application:

Biological laboratory: used for microbial culture, molecular biology experiments, cell experiments, etc., to ensure that contamination is avoided during the experimental process.

Clinical laboratory: used for clinical testing, biochemical analysis, immunological experiments, etc., to improve the accuracy of test results.

Medical R&D laboratory: used for new drug development, drug screening and other experiments to ensure the safety and effectiveness of the experiments.

Vaccine production laboratory: used in vaccine production, quality control and other processes to ensure vaccine quality and safety.

Maintenance:

Regular cleaning: The surface of the workbench can be wiped with a damp cloth. Avoid using corrosive cleaning agents. Regularly clean the filter to ensure its normal working efficiency.

Regularly replace filters: Depending on the frequency of workbench use and environmental conditions, replace HEPA filters regularly.

Pay attention to moisture prevention: The interior of the ultra clean workbench should be kept dry to avoid equipment failure caused by moisture.

Operating procedures: When using an ultra clean workbench, follow the operating procedures to avoid equipment damage caused by improper operations.

In short, ultra-clean workbenches play an important role in hospitals or laboratories. Correct use and maintenance of ultra-clean bench helps to protect laboratory biosafety and improve the accuracy of experimental results. Laboratory staff should be proficient in the use and maintenance of the ultra-clean bench to provide strong support for the sustainable development of hospital laboratories.

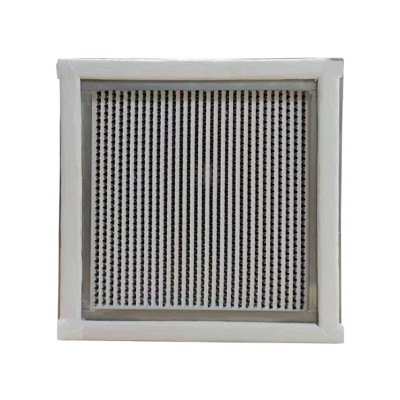

About us:

Snyli Environmental Technology (Shandong) Co., Ltd focuses on the research and development and production of air filtration products, with a sense of safety and security, and values customer experience, constantly pursuing progress. Customers who use SNYLI products are located in various countries and regions around the world. If you are interested in our products, please feel free to inquire!

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()