Comparison of Clean Booths and Clean Rooms

Clean rooms and clean booths are both facilities used to control fine dust and impurities in the environment, and are mainly used in industries with very high environmental requirements, such as semiconductor manufacturing and pharmaceutical production. The common point is that they can provide a clean, dust-free working environment, thus ensuring product quality and productivity.

The differences between the two are as follows:

1. Using different materials

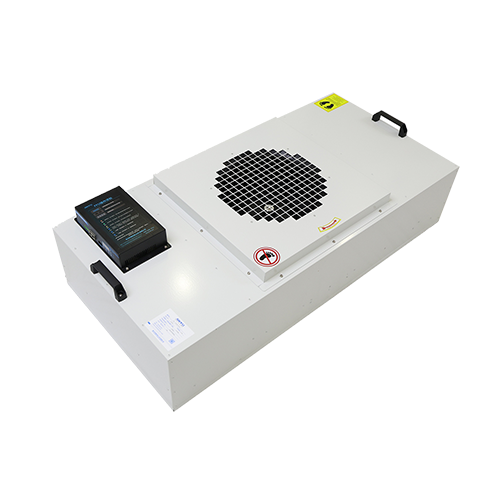

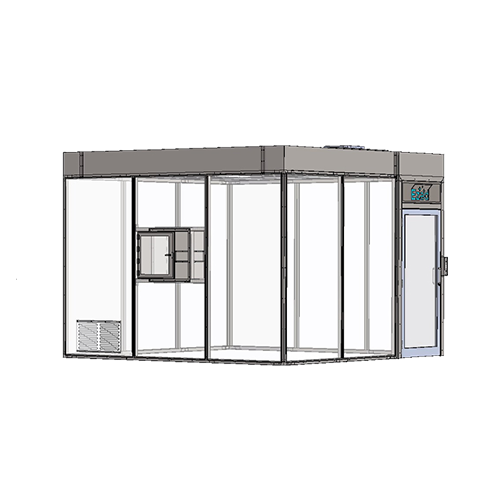

The clean booth generally uses industrial aluminium profiles as the frame, with plexiglass or anti-static grid curtains installed around the perimeter and on the top to achieve visual permeability. The air supply part adopts FFU clean air supply unit.

Clean room is equivalent to a large room for “luxury decoration”, the ceiling using foam colour steel or rock wool board, there is an independent air conditioning air supply system, the air through the primary, middle and high efficiency of a total of three levels of filtration, personnel and materials with a air shower and transfer window for clean filtration.

2. Clean room is generally larger than the clean booth.

Clean booth is built in the clean room, in general, is a kind of relatively closed environment using industrial aluminium profiles and plexiglass barrier up, above the clean booth, using HEPA and FFU air supply unit composition. Clean room is a specially designed room, the room can be excluded from the microparticles, harmful air, bacteria and other pollutants, and will continue to control the indoor temperature, cleanliness, pressure, air velocity and airflow distribution, noise and vibration and lighting, static electricity within a certain range of demand.

Clean rooms typically have larger capacities and areas and are often used in large production lines or factories. They are more complex in design and require specialised air handling equipment and control systems to ensure that a constant level of cleanliness is maintained throughout the area.

Clean booths are relatively small in size and are usually a simple clean environment facility that can be moved or fixed to a specific work area. The use of a clean booth creates a clean environment in a small area and is suitable for some work scenarios that require localised dust free requirements.

3. There is a big difference between the two construction costs

Clean booth is usually built in the clean room, so do not need to consider the air shower room, transfer window and air conditioning air supply system and other issues, which greatly saves the cost, the total construction cost of clean booths is 40% -60% of the clean room.

| Related products: | ||

|---|---|---|

|  |  |

| FFU | Clean booth | Pass box |

In general, the construction of the clean booth is fast, the construction process does not affect the operation of other equipment, and is easy to disassemble and can be reused. Clean room construction is slow and costly, but the facilities are more complete. Customers can choose the right way according to their needs. SNYLI can provide air filtration solutions for your clean room project, welcome to enquire!