Introduction:

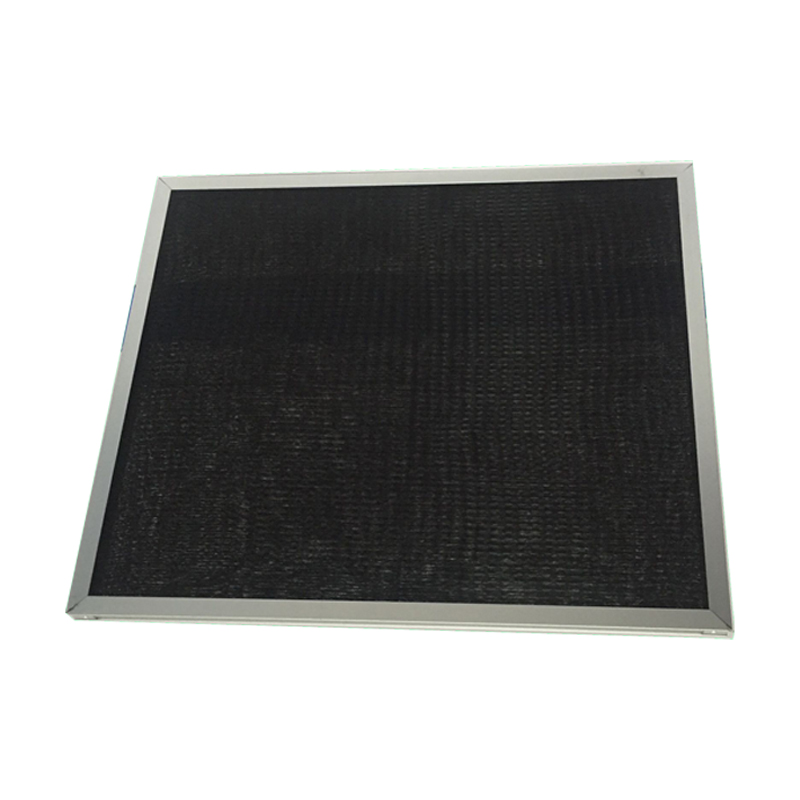

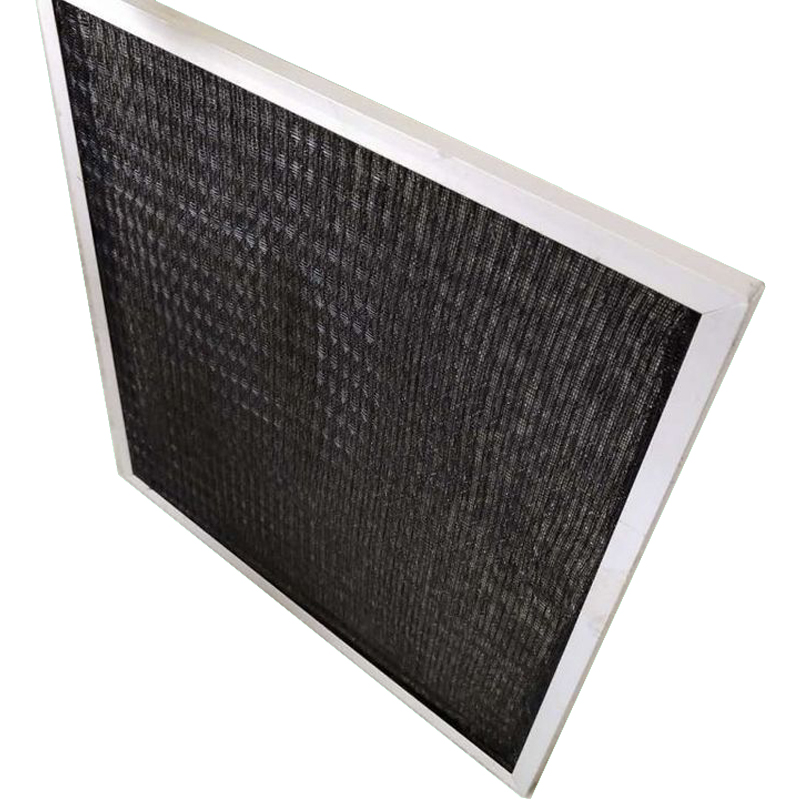

Nylon mesh filters are mainly used to filter large coarse dust and foreign objects visible to the naked eye in the air, commonly used in the coarse filtration section of multi-stage filtration systems, or in the supply air filtration system of dust removal systems with low requirements.

![HVAC Nylon Mesh Filter HVAC Nylon Mesh Filter]()

Outer frame | Aluminum profile frame, aluminum plate folding frame, galvanized frame, stainless steel frame |

Filter material | Nylon mesh woven from PP/PA/PE and other monofilaments as materials |

Filter level | G1/G2 |

Maximum temperature | 80 ℃ |

Applicable | Coarse dust filtration, generally used in fresh air units, air outlets and other occasions of contact with the outside air. |

Common dimensions:

Width (mm) | Height (mm) | Thickness (mm) | Rated airflow (m3/h) | Initial resistance (≤Pa) | Filtration area (m2) |

592 | 592 | 10 | 3200 | 20 | 0.7 |

592 | 287 | 10 | 1600 | 20 | 0.34 |

592 | 490 | 10 | 2600 | 20 | 0.58 |

592 | 592 | 21 | 3200 | 20 | 0.7 |

592 | 287 | 21 | 1600 | 20 | 0.34 |

592 | 490 | 21 | 2600 | 20 | 0.58 |

Features:

1. Can be cleaned multiple times, reused, and has a long service life.

2. Extremely low resistance, strong dust resistance, and easy replacement.

3. It can be made into combination connected structures such as hinge type and pull-out type, which is convenient for on-site installation.

4.The thickness usually includes 10mm, 15mm, 18mm, 21mm, etc., and can be customized according to needs.

Applications:

01 Office buildings, conference rooms, hospitals, shopping malls, gymnasiums, airports and other large civil building ventilation system;.

02 General factory centralised ventilation and air-conditioning system.

03 Primary filtration in centralised ventilation and air-conditioning system of clean room.

04 Clean room return air primary filtration

Cleaning & Maintenance Tips:

1. Regular cleaning

Nylon mesh filter will accumulate dust, bacteria and other impurities after a period of use, affecting the filtering effect. Therefore, regular cleaning is essential. The frequency of cleaning can depend on the situation, and it is generally recommended that a thorough cleaning be carried out every quarter.

2. Selection of cleaning tools

When cleaning nylon filters, appropriate cleaning tools should be selected to avoid damage to the filter. You can use a soft bristled brush, vacuum cleaner, or faucet for cleaning. Gently wipe or rinse with water, taking care not to apply too much force to avoid damaging the filter structure.

3. Warm water flushing

Nylon mesh filters can be cleaned with warm water, and the temperature is generally controlled below 40 ℃. Warm water can effectively remove grease and stains from nylon filters without damaging the filter itself. If there are stubborn stains on the filter, you can add an appropriate amount of neutral detergent for cleaning.

4. Dry in the shade or dry at low temperature

The cleaned nylon filter should be placed in a well ventilated area for shade drying, avoiding direct sunlight as much as possible. If time is tight, low-temperature drying can also be chosen. But pay attention to controlling the drying temperature to avoid damage to the filter screen caused by excessive temperature.

5. Regularly replace the nylon filter screen

Nylon filter screens also have a lifespan, and regular replacement of the filter screen can ensure filtration efficiency and air quality.