Introduction:

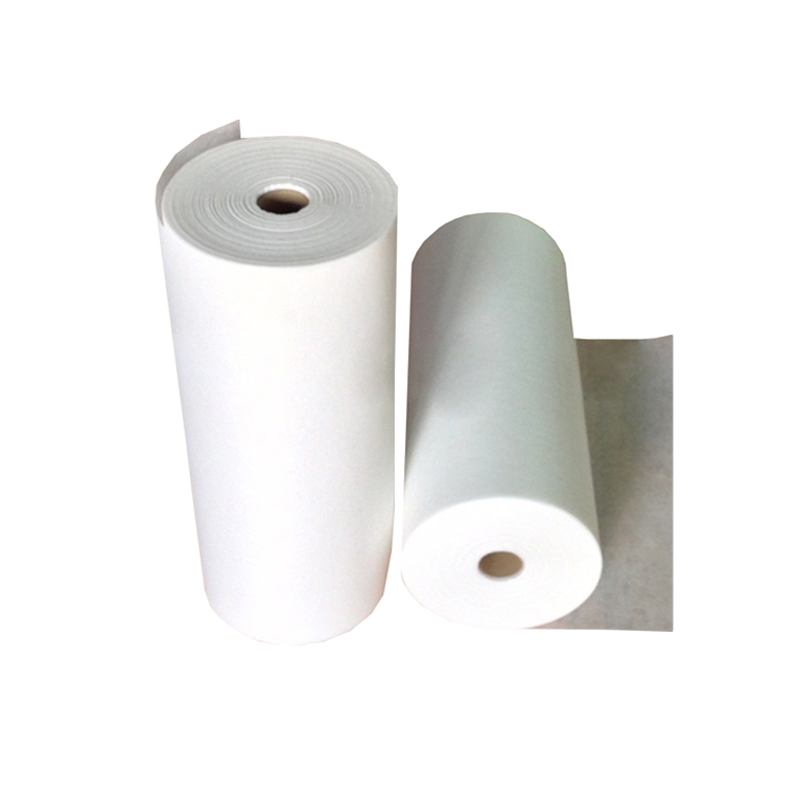

Polytetrafluoroethylene (PTFE) high efficiency air filtration material has been widely used in the electronics industry and cleanrooms for its high filtration efficiency, low initial resistance, no boron release, etc.

PTFE is essentially a kind of fibre filter material, the average diameter of its fibres is 60~85nm, much lower than the glass fibre filter material of 668.8nm.The filtration efficiency of high efficiency PTFE is comparable with that of the glass fibre filter material and its initial resistance is less than 50% of that of the glass fibre filter material.However, the dust holding performance of PTFE filter material is not as good as that of the glass fibre filter material, and it is more suitable for application in the places where there are regeneration or pre-filtering devices.

![PTFE Air Filter Media PTFE Air Filter Media]()

Common dimensions:

Width mm | Weight g/m2 | Thickness mm | Pressure Drop Pa@5.3cm/s | Filtration Efficiency % | Size Range um | Filter Grade |

1850 | 80 | 0.3-0.4 | 100-140 | ≥99.95 | 0.3-0.5 | H13 |

1850 | 80 | 0.3-0.4 | 140-190 | ≥99.995 | 0.3-0.5 | H14 |

1850 | 80 | 0.3-0.4 | 190-240 | ≥99.999 | 0.1-0.2 | U15 |

1850 | 80 | 0.3-0.4 | 240-290 | ≥99.9999 | 0.1-0.2 | U16 |

Performance Characteristics:

1. High efficiency filtration performance: PTFE air filter paper has a microporous structure, which can efficiently filter tiny particles and pollutants in the air.

2. High temperature resistance performance: PTFE material has good high temperature resistance performance, suitable for filtration requirements in high temperature environments.

3. Chemical resistance: PTFE has excellent chemical resistance and can resist the erosion of many chemical substances.

4. Low adhesion performance: PTFE surface has low adhesion, not easy to be adhered by pollutants, which is conducive to maintaining filtration efficiency.

5. Extremely low coefficient of friction: PTFE material surface has a very low coefficient of friction, which helps to reduce the resistance in the filtration process and improve filtration efficiency.

Application Scenario:

Medical equipment: used for air filtration of medical equipment to guarantee clean medical environment.

Laboratory: used in the filtration of laboratory ventilation system to prevent laboratory air pollution.

Electronic industry: used for air filtration of electronic equipment to protect the equipment from dust and foreign matter.

Food Processing: Used in the air filtration of food processing industry to protect the quality of food.

![Applications Applications]()

Precautions for use:

Check the integrity of the PTFE air filter paper before use to ensure that there are no breaks.

Replace the PTFE air filter paper regularly to maintain filtration efficiency.

Avoid overuse or improper use, which may affect the filtration effect.

About us:

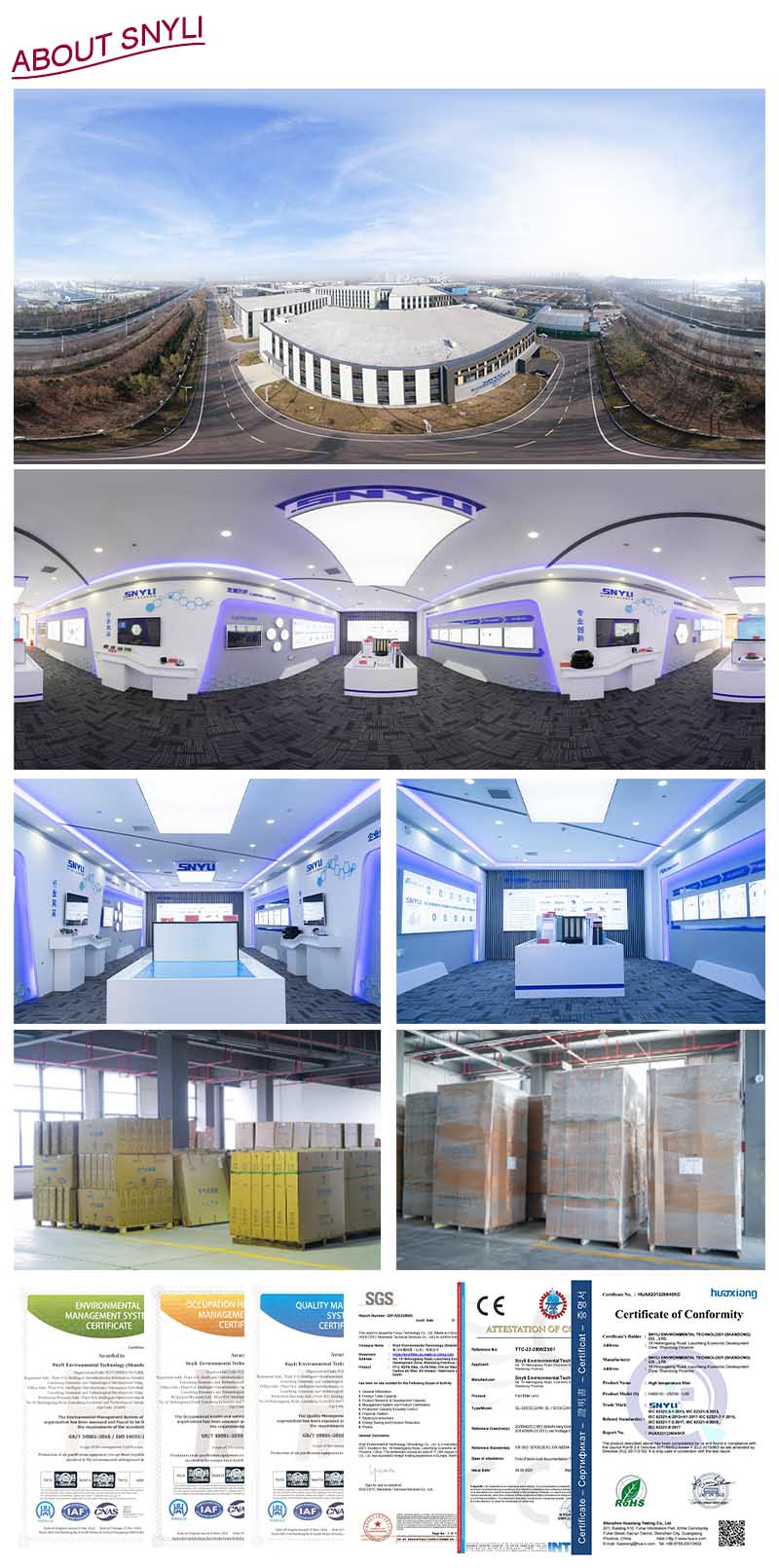

Snyli Environmental Technology (Shandong) Co., Ltd (hereinafter referred to as "SNYLI") is a well-known filter manufacturer in China, and its main products include: filters of various efficiency levels, synthetic fibre filter media, glass fibre filter media, PTFE filter media, FFU and other air purification products.

SNYLI is fully qualified and experienced in production. The factory in Liaocheng covers an area of more than 20,000 square metres, in which there is a separate R&D laboratory, thus ensuring that SNYLI's products are always advancing with the times.

![Snyli Environmental Technology (Shandong) Co., Ltd Snyli Environmental Technology (Shandong) Co., Ltd]()