Introduction:

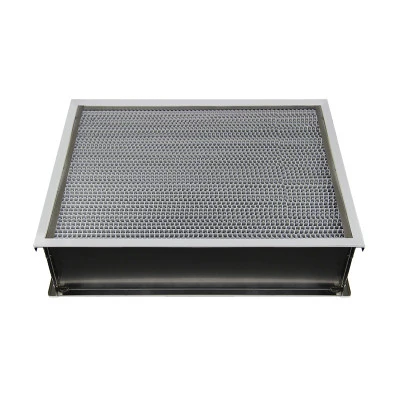

The 24x24x22 Bag Filter is a medium-efficiency air filtration device designed with a suspended bag-shaped filter material. Its core advantage lies in the three-dimensional filtration space formed by the multi-bag structure.

This filter effectively increases the filtration area through the three-dimensional arrangement of synthetic fiber or glass fiber filter bags. It is not only suitable for the central air conditioning units of commercial buildings, but also can meet the pre-filtration requirements of industrial workshops such as electronics and food. It is especially suitable for ventilation systems with high dust loads. While ensuring the filtration effect, it reduces the maintenance frequency, and the comprehensive operating cost is reduced by more than 30% compared with traditional filters.

![POCKET FILTER POCKET FILTER]()

Frame | Galvanized steel / ABS / Aluminium alloy / Stainless steel |

Media | Snythetic fiber or glass fiber |

Design | Pocket type |

Std. EN779:2012 | G4-F9 |

Maximum temperature | 80℃ |

Maximum relative humidity | 100% |

Customized size | Available |

Common Models:

Nominal Size (inches) | Actual Size

(mm) | Bags | Filtration area

(m2) | Air flow /initial resistance

(m3/h / Pa) | Efficiency

EN779 |

Width

| Height

| Depth

|

24 x 24 x 15 | 592 | 592 | 380 | 8 | 3.6 | 1950 / 40 | 3200 / 70 | F5 |

20 x 24x 15 | 490 | 592 | 380 | 6 | 2.7 | 1500 / 40 | 2850 / 70 | F5 |

12 x 24x15 | 287 | 592 | 380 | 3 | 1.4 | 950 / 40 | 1500 / 70 | F5 |

20x 20x 15 | 490 | 490 | 380 | 5 | 2.0 | 1150 / 40 | 2180 / 70 | F5 |

20 x 16 x 15 | 490 | 390 | 380 | 4 | 1.6 | 850 / 40 | 2150 / 70 | F5 |

12x 12 x 15 | 287 | 287 | 380 | 2 | 0.44 | 350 / 40 | 650 / 70 | F5 |

24 x 24 x 19 | 592 | 592 | 480 | 8 | 4.6 | 2150 /40 | 3400 / 70 | F5 |

20 x 24x 19 | 490 | 592 | 480 | 6 | 3.4 | 1800 / 40 | 3050 / 70 | F5 |

12 x 24x19 | 287 | 592 | 480 | 3 | 1.7 | 1050 /40 | 1700 / 70 | F5 |

20x 20x 19 | 490 | 490 | 480 | 5 | 2.35 | 1350 /40 | 2350 / 70 | F5 |

20 x 16 x19 | 490 | 390 | 480 | 4 | 1.5 | 1050 /40 | 2350 / 70 | F5 |

12x 12 x 19 | 287 | 287 | 480 | 2 | 0.5 | 450 /40 | 850 / 70 | F5 |

24 x 24 x 21 | 592 | 592 | 534 | 8 | 4.74 | 2380 /40 | 4200 / 70 | F5 |

20 x 24x 21 | 490 | 592 | 534 | 6 | 4.3 | 2150 /40 | 3200 / 70 | F5 |

12 x 24x 21 | 287 | 592 | 534 | 3 | 1.8 | 1250 / 40 | 1950 / 70 | F5 |

20x 20x 21 | 490 | 490 | 534 | 5 | 2.5 | 1550 / 40 | 2500 / 70 | F5 |

20 x 16 x 21 | 490 | 390 | 534 | 4 | 1.6 | 1250 / 40 | 2650 / 70 | F5 |

12x 12 x 21 | 287 | 287 | 534 | 2 | 0.6 | 500 / 40 | 950 / 70 | F5 |

24 x 24 x25 | 592 | 592 | 600 | 8 | 5.7 | 2650 / 40 | 4500 / 70 | F5 |

20 x 24x 25 | 490 | 592 | 600 | 6 | 4.3 | 2450 / 40 | 3800 / 70 | F5 |

12 x 24x25 | 287 | 592 | 600 | 3 | 2.2 | 1450 / 40 | 2100 / 70 | F5 |

20x 20x 25 | 490 | 490 | 600 | 5 | 2.94 | 1700 / 40 | 2950 / 70 | F5 |

Performance advantages:

1.Excellent filtration performance

24x24x22 Bag Filter adopts high-quality synthetic fiber or glass fiber filter media, which can effectively capture dust, pollen and other particles as small as 1μm, with high filtration efficiency and ensuring air cleanliness.

2. Large filtration area & high dust holding capacity

The multi-bag structure design significantly increases the effective filtration area. The dust holding capacity is 3 to 5 times higher than that of the plate filter, and it has a long service life.

3. Low air resistance & energy-saving operation

Optimize the design of the air flow channel. During operation, the wind resistance rises steadily, reducing the energy consumption of the fan and lowering the operating cost of the system.

4. Stable structure & easy to maintain

Metal frame support, with strong anti-deformation ability; Easy to replace, convenient to maintain and reduce downtime.

5. Wide applicability

Bag Air Filter is suitable for various scenarios such as commercial central air conditioning, industrial clean workshops, pharmaceuticals, food processing, etc., and is especially suitable for environments with high dust load.

6. Flexible configuration

Supports customization of different bag numbers (4-12 bags) and sizes to meet various air volume and space requirements.

Application places:

The 24x24x22 Bag Filter, with its large dust holding capacity and efficient filtration characteristics, is particularly suitable for medium and high dust concentration places that require long-term stable operation, providing reliable protection for the back-end precision filtration system.

![Applications Applications]()

1. Commercial building field

Fresh air and return air filtration for central air conditioning systems in office buildings, shopping malls and hotels

Air handling units for large venues (theaters, exhibition centers, etc.)

2. Industrial manufacturing environment

Air pretreatment in the electronic component production workshop

Dust collection for automotive manufacturing spray painting lines and welding workshops

Primary filtration of ventilation systems in food processing plants (dairy products, baking, etc.)

3. Medical and pharmaceutical industry

Primary air purification in the ordinary production area of a pharmaceutical factory

Ventilation systems for general wards and public areas in hospitals

4. Public facilities and places

Air circulation treatment in subway stations and airport terminals

Air conditioning units for large public buildings such as schools and libraries

5. Special industrial applications

Dust protection for ventilation equipment in chemical plants and power stations

Pre-filtration for high-dust environments in the cement and metallurgical industries

6. Cleanroom system

As the primary protection unit of the three-stage filtration system in the cleanroom

The pre-filtration stage in biological laboratories and PCR laboratories

7. Commercial ventilation equipment

The pre-filter device of the fresh air unit

The primary filtration unit of the air purification equipment

8. Process production requirements

Fiber and dust interception in printing workshops and textile factories

The wood chip collection system in the woodworking processing workshop

About us:

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, registered in Liaocheng City, Shandong Province, mainly engaged in air filtration products. Since the establishment of our company, we have been continuously deepening our research and development to improve our strength, and now we have mastered many patents and obtained ISO/CE certificates.

After more than ten years, SNYLI has set up branches in many places in China and a trading company in Jinan City, Shandong Province. At present, SNYLI products have been exported to both home and abroad, and we have signed long-term co-operation agreements with customers in many countries.

We always put the interests of customers in the first place, regularly follow up customer feedback, and strive to improve our own strength, and the constant pursuit of progress.

Giving us a chance to co-operate will be a decision that benefits both parties! SNYLI welcomes your enquiry!

![About SNYLI About SNYLI]()

SNYLI Production workshop:

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.

![SNYLI production workshop SNYLI production workshop]()