Introduction:

Gel Seal HEPA filter is a high-performance filtration device with liquid tank sealing technology, which utilizes a non-Newtonian fluid (such as jelly glue) to form a dynamic seal within the frame tank, ensuring zero leakage between the filter media and the frame. Its advantages include: high efficiency filtration (retention rate of 0.3μm particles ≥ 99.99%), excellent sealing stability (adaptable to positive/negative pressure and vibration environments), as well as long service life and easy maintenance.The Gel Seal Filter is widely used in biopharmaceuticals, electronic cleanrooms, hospital operating rooms and other areas with strict requirements for air cleanliness.

![Gel Seal Dust Collector HEPA Filter Gel Seal Dust Collector HEPA Filter]()

Frame | Anodized aluminum profile |

Protective net | Double-sided |

Std. EN1822:2009 | H13 / H14 / U15 |

Efficiency | 99.99%,99.999% at 0.3μm, 99.9995% at 0.12μm (DOP/PSL/PAO Counting method) |

Sealant | Urethane gel sealant |

Filter media | Ultrafine Glass Fibre |

Separator | Hot melt |

Maximum temperature | 80℃ |

Maximum relative humidity | 100%RH (non-condensing condition) |

Gasket | EPDM |

Customized size | Available |

Style | Top gel seal, side gel seal |

Tested one by one before leaving the factory and can be delivered only after passing the test. Reliable quality, stable performance, can be customised with non-standard size. |

Performance Characteristics:

1. High-efficiency filtration: Gel Seal HEPA filter has a filtration efficiency of ≥99.99% for particles of 0.3μm and above, ensuring ultra-high cleanliness.

2. Liquid tank sealing: non-Newtonian fluid (such as jelly glue) is used for dynamic sealing, eliminating leakage and adapting to positive/negative pressure and vibration environments.

3. Stable and durable: anti-corrosion, moisture-proof, long-term stability of sealing performance, long service life.

4. Easy maintenance: integral structure design, convenient replacement.

Common Dimensions:

Dimensions(mm) | Gel Seal Method | Rated Air flow(m³/h) | Initial Resistance(Pa) |

H14 | U15 |

412*412*93 | Side gel seal | 500 | 240 | 260 |

631*631*93 | 1200 | 240 | 260 |

758*631*93 | 1500 | 240 | 260 |

1026*631*93 | 2000 | 240 | 260 |

610*305*95(85+15) | Top gel seal | 500 | 240 | 260 |

610*610*95(85+15) | 1200 | 240 | 260 |

762*610*95(85+15) | 1500 | 240 | 260 |

915*610*95(85+15) | 1800 | 240 | 260 |

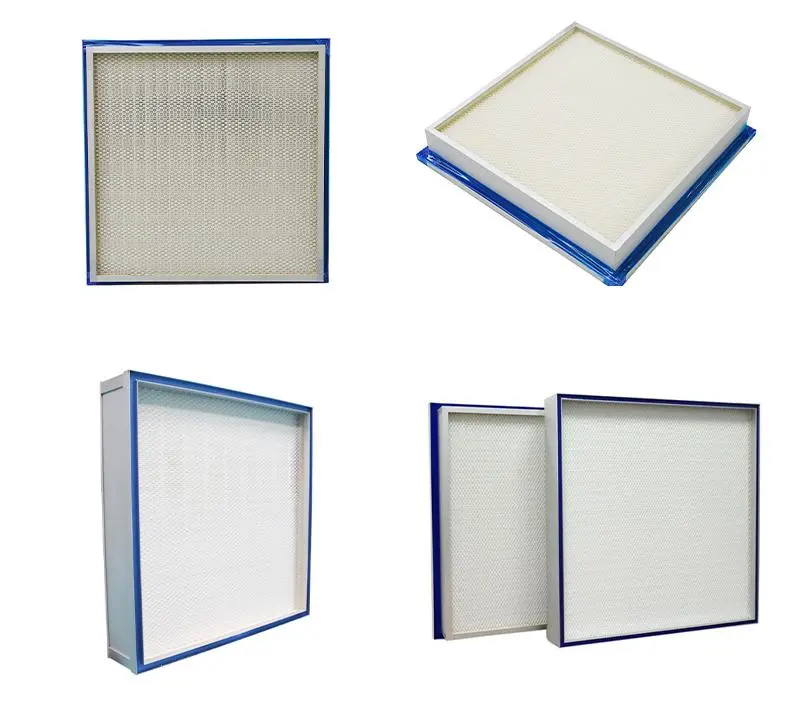

Different Structure:

![Side gel seal hepa filter Side gel seal hepa filter]() |

Side Gel Seal HEPA Filter |

![Top Gel Seal HEPA filter Top Gel Seal HEPA filter]() |

Top Gel Seal HEPA Filter |

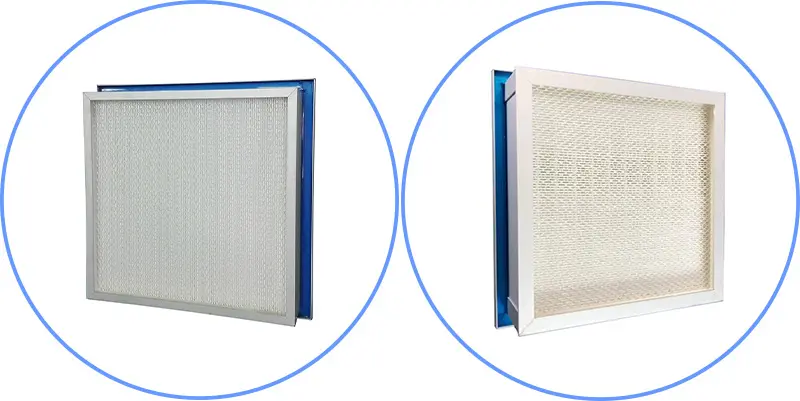

Application:

1. Biomedical industry: Gel Seal HEPA filter can be used in clean rooms, aseptic production lines, vaccine production and biosafety laboratories to ensure that the air is sterile and dust-free, in line with GMP standards.

2. Electronic semiconductor industry: Gel Seal Mini pleat filter can be applied to chip manufacturing, LCD panel production and other ultra-clean environments to prevent micro-dust contamination of precision components.

3. Medical and health institutions: High Efficiency Filters can be used in operating rooms, ICUs, negative pressure wards and other areas to control the spread of pathogenic microorganisms and ensure the safety of the medical environment.

4. Food and cosmetic industry: Industrial HEPA Filter System can provide clean air in the filling workshop, packaging area and other key links to prevent product contamination and meet the hygienic production requirements.

![APPLICATIONS APPLICATIONS]()

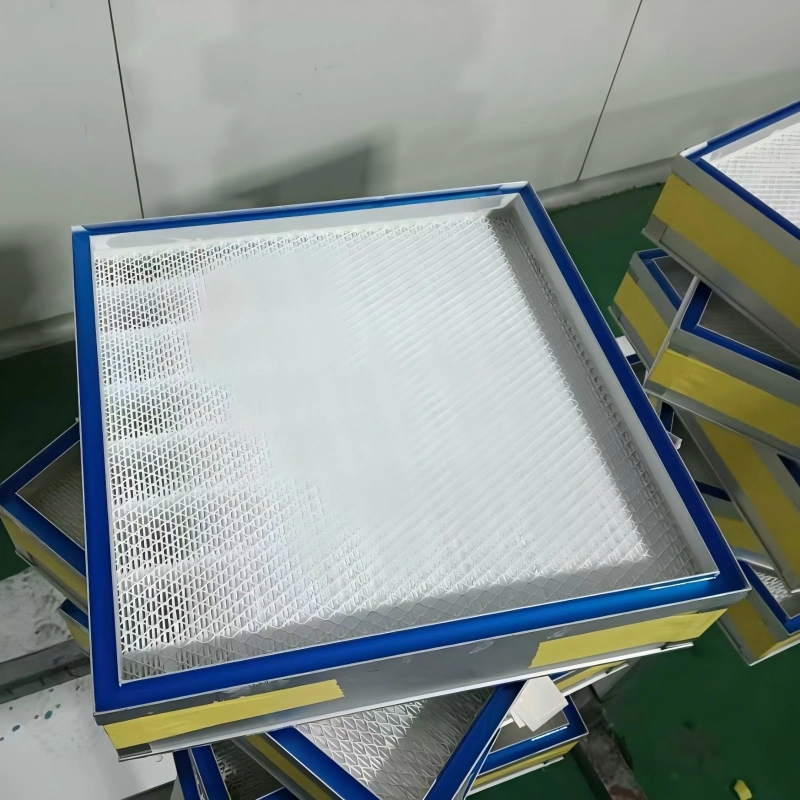

SNYLI Production workshop:

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.

![SNYLI PRODUCTION WORKSHOP SNYLI PRODUCTION WORKSHOP]()

About us:

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, registered in Liaocheng City, Shandong Province, mainly engaged in air filtration products. Since the establishment of our company, we have been continuously deepening our research and development to improve our strength, and now we have mastered many patents and obtained ISO/CE certificates.

After more than ten years, SNYLI has set up branches in many places in China and a trading company in Jinan City, Shandong Province. At present, SNYLI products have been exported to both home and abroad, and we have signed long-term co-operation agreements with customers in many countries.

We always put the interests of customers in the first place, regularly follow up customer feedback, and strive to improve our own strength, and the constant pursuit of progress.

Giving us a chance to co-operate will be a decision that benefits both parties! SNYLI welcomes your enquiry!

![SNYLI FACTORY SNYLI FACTORY]()