Introduction:

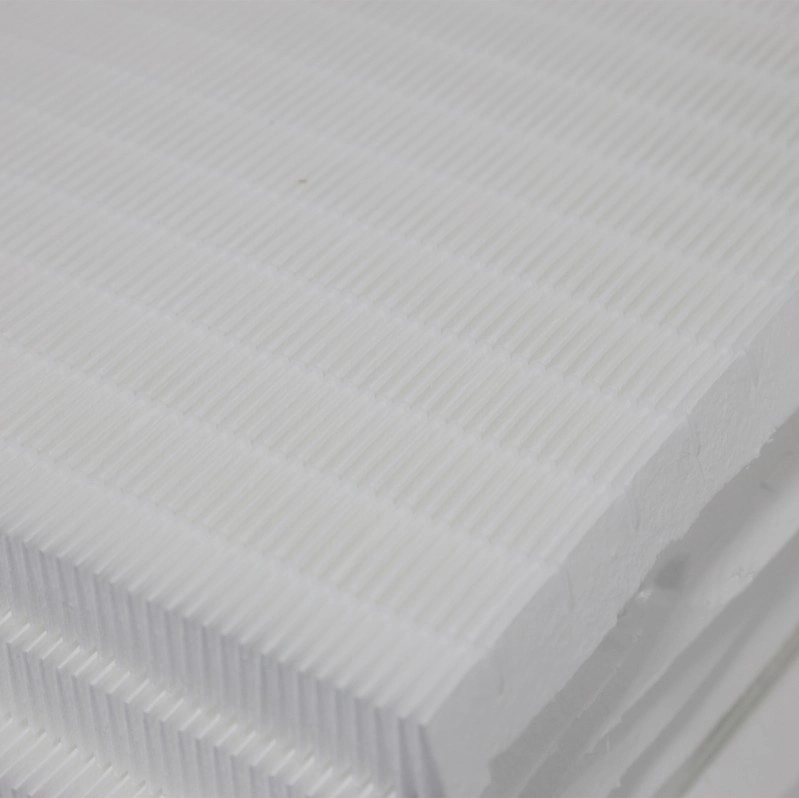

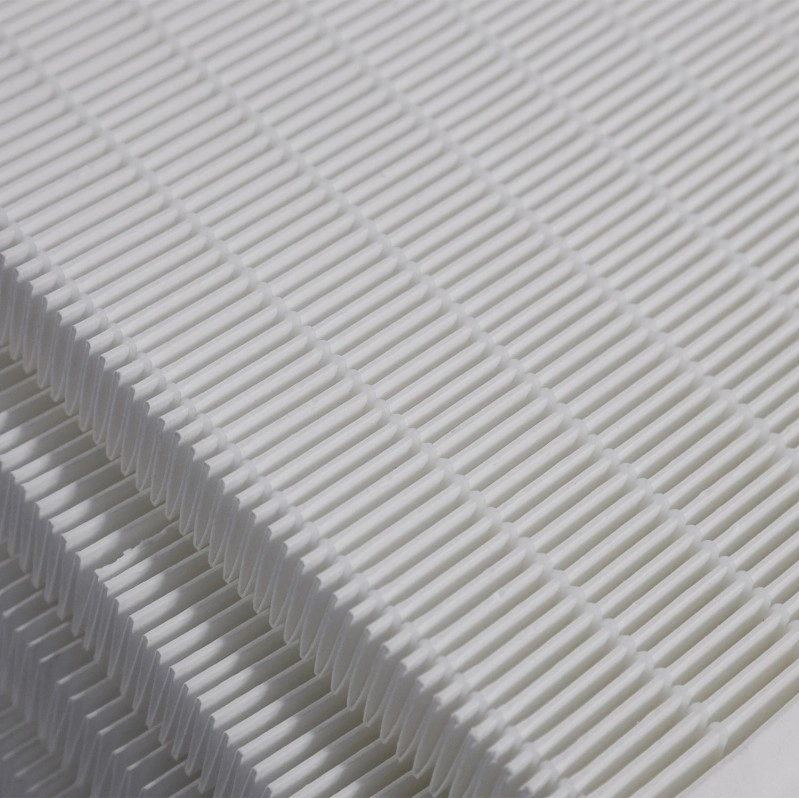

The Mini Pleat HEPA (High Efficiency Particulate Air Filter) is an efficient Industrial HEPA Filter device that uses ultrafine glass fiber filter paper as the filtering medium and uses hot melt adhesive instead of traditional metal separators to fix the pleats of the filter material.

This kind of High Efficiency Filters has the characteristics of compact structure, light weight, low resistance and high efficiency. The filtration efficiency can reach above H13 level (the interception rate of 0.3μm particles is ≥99.97%).

By densely distributing Z-shaped pleated filter media to increase the filtration area, it ensures a high dust holding capacity while reducing air resistance. It is widely used in clean rooms, biosafety laboratories, hospital operating rooms, electronics industry and other places with strict requirements for air cleanliness, and can effectively filter bacteria, viruses, and sub-micron particles.

Frame | Anodized aluminum profile |

Media | Ultra fine glass fiber |

Media guard | Painted iron mesh |

Std. EN1822:2009 | E10 / E12/ H13 / H14 / U15 / U16 95% / 99.97% / 99.99% / 99.999% at 0.3μm 99.9995% / 99.99995% at 0.12μm (DOP/PSL/PAO Counting method) |

Maximum temperature | 70℃ |

Maximum relative humidity | 100% |

Customized size | Available |

![Mini pleat HEPA filter Mini pleat HEPA filter]()

Common dimensions:

Size

(mm) | CMH | I.N.P

(Pa) | Filter

object

(μm) | EFF.

(%) | Filtration

Class | Filtration

Area

(m2) |

305*610*50 | 350/700 | <30/70 | 0.3 | 85≤E<95 | E10 | 3.85 |

610*610*50 | 650/1300 | <30/70 | 0.3 | 85≤E<95 | E10 | 7.44 |

1220*610*50 | 1200/2400 | <30/70 | 0.3 | 85≤E<95 | E10 | 14.59 |

305*610*50 | 350/700 | <55/120 | 0.3 | 95≤E<99.5 | E11 | 3.85 |

610*610*50 | 650/1300 | <55/120 | 0.3 | 95≤E<99.5 | E11 | 7.44 |

1220*610*50 | 1200/2400 | <55/120 | 0.3 | 95≤E<99.5 | E11 | 14.59 |

305*610*50 | 350/700 | <75/180 | 0.3 | 99.5≤E<99.95 | E12 | 3.85 |

610*610*50 | 650/1300 | <75/180 | 0.3 | 99.5≤E<99.95 | E12 | 7.44 |

1220*610*50 | 1200/2400 | <75/180 | 0.3 | 99.5≤E<99.95 | E12 | 14.59 |

305*610*50 | 350/700 | <100/205 | 0.3 | 99.95≤E<99.995 | H13 | 3.85 |

610*610*50 | 650/1300 | <100/205 | 0.3 | 99.95≤E<99.995 | H13 | 7.44 |

1220*610*50 | 1200/2400 | <100/205 | 0.3 | 99.95≤E<99.995 | H13 | 14.59 |

305*610*50 | 350/700 | <110/220 | 0.3 | 99.995≤E<99.9995 | H14 | 3.85 |

610*610*50 | 650/1300 | <110/220 | 0.3 | 99.995≤E<99.9995 | H14 | 7.44 |

1220*610*50 | 1200/2400 | <110/220 | 0.3 | 99.995≤E<99.9995 | H14 | 14.59 |

305*610*50 | 350/700 | <160/295 | 0.12 | 99.9995≤E<99.9997 | U15 | 3.85 |

610*610*50 | 650/1300 | <160/295 | 0.12 | 99.9995≤E<99.9997 | U15 | 7.44 |

1220*610*50 | 1200/2400 | <160/295 | 0.12 | 99.9995≤E<99.9997 | U15 | 14.59 |

305*610*50 | 350/700 | <175/320 | 0.12 | 99.9997≤E<99.99997 | U16 | 3.85 |

610*610*50 | 650/1300 | <175/320 | 0.12 | 99.9997≤E<99.99997 | U16 | 7.44 |

1220*610*50 | 1200/2400 | <175/320 | 0.12 | 99.9997≤E<99.99997 | U16 | 14.59 |

Performance characteristics:

1. High-efficiency filtration: The filtration efficiency of the Industrial HEPA Filter for 0.3μm particles is above 99.97% (H13 grade and above), and it can effectively intercept bacteria, viruses and fine particles.

2. Low air resistance, energy saving: The mini pleat design increases the filtration area, reduces air flow resistance, lowers energy consumption, and operates more economically.

3. Compact and lightweight structure: This HEPA filter adopts a design without metal separators, is small in size, light in weight, and convenient for installation and maintenance. It is suitable for places with limited space.

4. High dust holding capacity and long service life: The superfine glass fiber filter material combined with a pleated structure has a large dust holding capacity, a long service life, and reduces the frequency of replacement.

Application environment:

1. Medical field: HEPA Units is used in hospital operating rooms, sterile wards, laboratories and biosafety cabinets to ensure clean air and prevent microbial contamination.

2. Electronics industry: It is applied in dust-free environments such as semiconductor workshops and precision instrument production to prevent fine dust from affecting product yield.

3. Food and Pharmaceutical industry: In GMP clean workshops, drug production and packaging areas, HEPA Filter Ventilation System is used to ensure that air hygiene standards are met.

4. Public facilities: Such as fresh air systems in airports, subways, and high-end office buildings, Industrial HEPA Filter is used to filter PM2.5, bacteria, etc., and improve indoor air quality.

![Industrial HEPA filters application Industrial HEPA filters application]()

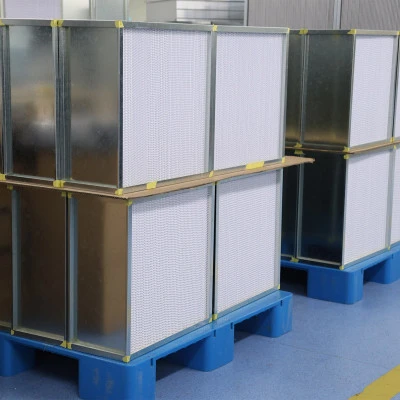

SNYLI Production workshop:

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.

![SNYLI HEPA filter workshop SNYLI HEPA filter workshop]()

About us:

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, registered in Liaocheng City, Shandong Province, mainly engaged in air filtration products. Since the establishment of our company, we have been continuously deepening our research and development to improve our strength, and now we have mastered many patents and obtained ISO/CE certificates.

After more than ten years, SNYLI has set up branches in many places in China and a trading company in Jinan City, Shandong Province. At present, SNYLI products have been exported to both home and abroad, and we have signed long-term co-operation agreements with customers in many countries.

We always put the interests of customers in the first place, regularly follow up customer feedback, and strive to improve our own strength, and the constant pursuit of progress.

Giving us a chance to co-operate will be a decision that benefits both parties! SNYLI welcomes your enquiry!

![SNYLI Factory SNYLI Factory]()