Introduction:

The Separator HEPA Filter is a filtration device that uses aluminum foil or paper separators to support the filter material. Its core feature is that the separators divide the filter paper into regular corrugated structures, thereby increasing the filtration area and maintaining the stability of the filter material.

This kind of deep pleat filter is usually used at the HEPA (High Efficiency Particulate Air) level. It can effectively capture particles of 0.3 microns and above in the air, with a filtration efficiency of over 99.97%. It is widely used in places with extremely high requirements for air cleanliness, such as clean rooms, hospitals, laboratories, and electronic manufacturing.

![Separator HEPA filter Separator HEPA filter]()

The deep pleated design endows the filter with higher mechanical strength, enabling it to withstand greater wind pressure and extend its service life. However, its volume is relatively large, and the airflow resistance is slightly higher than that of the mini pleat design. Separator HEPA Filter is suitable for environments with high requirements for the stability of filtration performance.

Housing | Usually made of metal, such as galvanized steel, aluminum alloy, stainless steel, used to protect the filter media, provide support. |

Filter Media | The core of a deep pleat HEPA filter. The filter media is usually made of high efficiency glass fibre material. |

Separators | Usually paper or aluminium foil, they are used to separate the filter media to ensure even distribution of air flow through the entire filter and to improve filtration efficiency. |

Gaskets | Sealing strips installed on the edges of the filter to ensure air tightness. |

Std. EN1822:2009 | E10 / E12 / H13 / H14 |

Efficiency | 95% 99.97%,99.99%,99.999% @0.3μm (DOP/PSL/PAO Counting method) |

Maximum temperature | 70℃ |

Maximum relative humidity: | 100% |

Customized size | Available |

Different structures:

Single header type | Double header type | Box type |

![Separator HEPA Filter Separator HEPA Filter]()

| ![Separator HEPA Filter Separator HEPA Filter]()

| ![Separator HEPA Filter Separator HEPA Filter]()

|

Common dimensions:

Size (mm) | Rated air flow(m3/h) | Recommended air flow | Initial pressure drop (Pa) | Efficiency(%) |

305×305×150 | 500 | 500 | ≤120Pa | 99.999 |

484×484×150 | 700 | 700 | ≤120Pa | 99.999 |

610×610×150 | 1000 | 1000 | ≤120Pa | 99.999 |

915×610×150 | 1500 | 1500 | ≤120Pa | 99.999 |

610×610×292 | 2000 | 2000 | ≤120Pa | 99.999 |

915×610×292 | 3000 | 3000 | ≤120Pa | 99.999 |

Features:

1. Separator support structure: The Separator HEPA Filter uses aluminum foil or paper separators to divide the filter paper into regular corrugated structures. This design not only increases the filtration area but also provides good mechanical support to ensure the stability of the filter material during operation.

2. Alternating arrangement of filter materials and separators: The filter materials and separators are alternately folded and arranged to form uniform air flow channels. This structure optimizes the air flow path, enhances the filtration efficiency, and simultaneously reduces air flow resistance.

3. Frame reinforcement design: The Separator HEPA Filter usually adopts a metal outer frame to ensure the stability and sealing of the overall structure, prevent the leakage of unfiltered air, and is suitable for places with high air pressure and high cleanliness requirements.

Applications:

1. Pharmaceutical industry: Deep Pleat HEPA filters are widely used in places such as pharmaceutical factories, aseptic production workshops, and hospital operating rooms to ensure the air cleanliness of the production environment and medical Spaces, prevent microbial and particulate contamination, and guarantee the quality of drugs and the safety of patients.

2. Electronics Industry: In environments with extremely high requirements for air cleanliness, such as semiconductor manufacturing and the production of precision electronic components, Deep Pleat filters are used to remove tiny particles in the air, prevent products from being contaminated, and ensure the stability of the production process and product quality.

3. Biological laboratories: In places such as biosafety laboratories, cell culture rooms, and genetic engineering laboratories, Deep Pleated Air filters can effectively Filter bacteria, viruses, and harmful particles in the air, providing a sterile environment for experiments and protecting the safety of laboratory personnel and experimental samples.

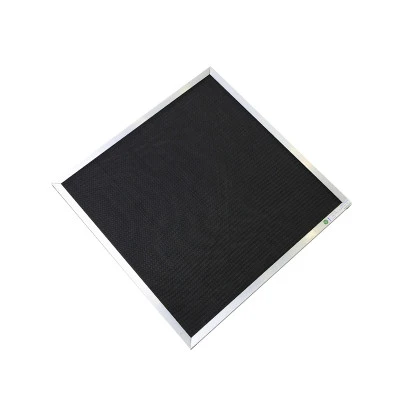

![Applications Applications]()

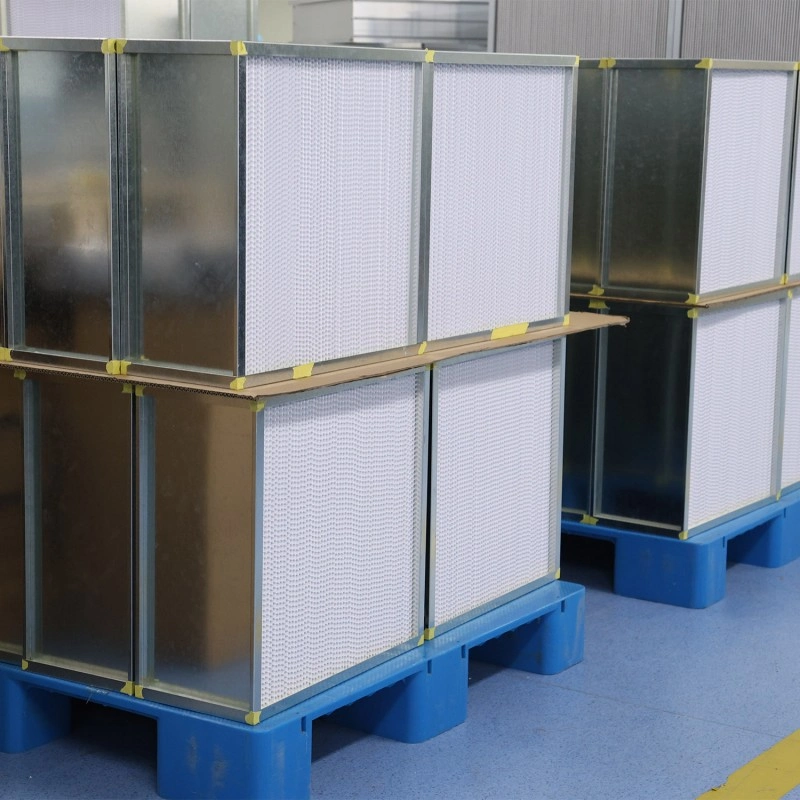

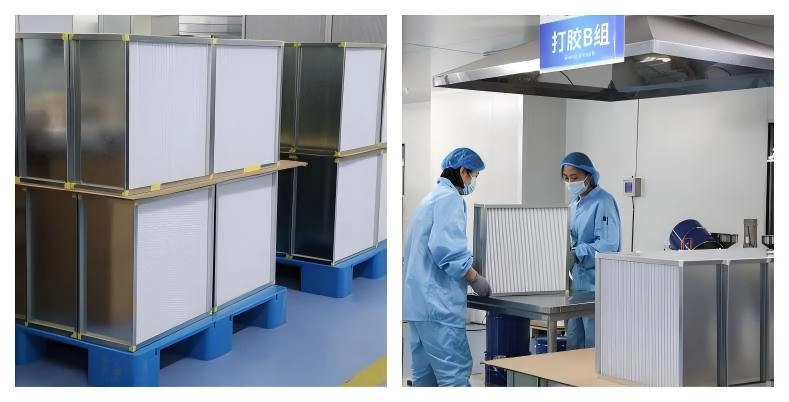

SNYLI Production workshop:

SNYLI factory is located in Liaocheng City, Shandong Province, China, with several independent clean production workshops, including FFU workshop, primary filter workshop, bag filter workshop, HEPA filter workshop and so on.

Professional technical team, independent warehouse and perfect service make SNYLI's popularity in the air filtration industry increasing.

![SNYLI Production Workshop SNYLI Production Workshop]()

About us:

Snyli Environmental Technology (Shandong) Co.,Ltd was established in 2010, registered in Liaocheng City, Shandong Province, mainly engaged in air filtration products. Since the establishment of our company, we have been continuously deepening our research and development to improve our strength, and now we have mastered many patents and obtained ISO/CE certificates.

After more than ten years, SNYLI has set up branches in many places in China and a trading company in Jinan City, Shandong Province. At present, SNYLI products have been exported to both home and abroad, and we have signed long-term co-operation agreements with customers in many countries.

We always put the interests of customers in the first place, regularly follow up customer feedback, and strive to improve our own strength, and the constant pursuit of progress.

Giving us a chance to co-operate will be a decision that benefits both parties! SNYLI welcomes your enquiry!

![SNYLI Factory SNYLI Factory]()