Introduction:

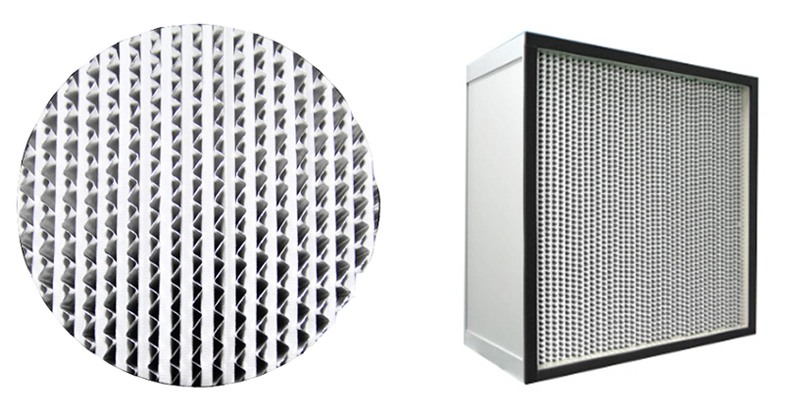

Deep Pleat HEPA Filters refer to an air filtration system consisting of multiple parallel metal partitions.These partitions are arranged in a series of panels and longitudinal rows inside the filter to form a number of independent filter units. Between the filter units, there are special fillers and fibre materials, etc. nested in each other, so that the air is twisted and reversed many times as it passes through the partitions, which increases the contact area between the air and the filter material, and thus achieves a highly efficient purification effect.

Frame | Galvanized, Aluminum & Stainless Steel |

Header | Box type, Single, Double header |

Media | Glass fiber |

Separator | Aluminum foil/Paper |

Gasket | EPDM |

Max. Temperature | ≦ 70℃ |

Max. Humidity | ≦ 100% RH |

![HVAC Industry Deep Pleat HEPA Filter HVAC Industry Deep Pleat HEPA Filter]()

Common dimensions:

Size

(mm) | CMH | I.N.P

(Pa) | F.N.P

(Pa) | Filter

object

(μm) | EFF.

(%) | Filtration

Class | Filtration

Area

(m2) |

305*610*150 | 500/700 | <100/130 | <350/500 | 0.3 | 85≤E<95 | E10 | 4.25 |

610*610*150 | 1000/1500 | <100/130 | <350/500 | 0.3 | 85≤E<95 | E10 | 7.97 |

1220*610*150 | 2000/2800 | <100/130 | <350/500 | 0.3 | 85≤E<95 | E10 | 15.68 |

1220*915*150 | 2800/3800 | <100/130 | <350/500 | 0.3 | 85≤E<95 | E10 | 23.60 |

305*610*150 | 500/700 | <120/150 | <350/500 | 0.3 | 95≤E<99.5 | E11 | 4.25 |

610*610*150 | 1000/1500 | <120/150 | <350/500 | 0.3 | 95≤E<99.5 | E11 | 7.97 |

1220*610*150 | 2000/2800 | <120/150 | <350/500 | 0.3 | 95≤E<99.5 | E11 | 15.68 |

1220*915*150 | 2800/3800 | <120/150 | <350/500 | 0.3 | 95≤E<99.5 | E11 | 23.60 |

305*610*150 | 500/700 | <140/170 | <350/500 | 0.3 | 99.5≤E<99.95 | E12 | 4.25 |

610*610*150 | 1000/1500 | <140/170 | <350/500 | 0.3 | 99.5≤E<99.95 | E12 | 7.97 |

1220*610*150 | 2000/2800 | <140/170 | <350/500 | 0.3 | 99.5≤E<99.95 | E12 | 15.68 |

1220*915*150 | 2800/3800 | <140/170 | <350/500 | 0.3 | 99.5≤E<99.95 | E12 | 23.60 |

305*610*150 | 500/700 | <170/200 | <350/500 | 0.3 | 99.95≤E<99.995 | H13 | 4.25 |

610*610*150 | 1000/1500 | <170/200 | <350/500 | 0.3 | 99.95≤E<99.995 | H13 | 7.97 |

1220*610*150 | 2000/2800 | <170/200 | <350/500 | 0.3 | 99.95≤E<99.995 | H13 | 15.68 |

1220*915*150 | 2800/3800 | <170/200 | <350/500 | 0.3 | 99.95≤E<99.995 | H13 | 23.60 |

305*610*150 | 500/700 | <190/220 | <350/500 | 0.3 | 99.995≤E<99.9995 | H14 | 4.25 |

610*610*150 | 1000/1500 | <190/220 | <350/500 | 0.3 | 99.995≤E<99.9995 | H14 | 7.97 |

1220*610*150 | 2000/2800 | <190/220 | <350/500 | 0.3 | 99.995≤E<99.9995 | H14 | 15.68 |

1220*915*150 | 2800/3800 | <190/220 | <350/500 | 0.3 | 99.995≤E<99.9995 | H14 | 23.60 |

Specification can be customised according to the actual needs of customers.

Features:

Long service life. Deep Pleat HEPA Filters are more robust due to the spacer design, which not only increases the life of the filter, but also reduces the frequency of maintenance and replacement of the filters, lowering operating costs.

Low resistance. The divider design of the separator air filter also results in lower resistance.

Diverse specification models are available. Deep Pleat HEPA Filter can be customised according to different use scenarios and needs, providing a variety of specifications and models to choose from, so that it can be better adapted to different air treatment systems and meet the needs of different users.

Application Fields:

Medical and health care field: In hospital operating theatres, sterile rooms and other places with extremely high requirements for air quality, Deep Pleat HEPA Filters can effectively remove bacteria, viruses and other harmful particles in the air, improve air cleanliness and provide a safe and reliable environment for patients;

Electronic manufacturing industry: In the manufacturing process of electronic products, tiny particles have an important impact on product quality;

Laboratories and clean rooms: In laboratories and clean rooms, Deep Pleat HEPA Filters can effectively remove dust, particles and harmful substances from the air and improve the accuracy of experimental results.

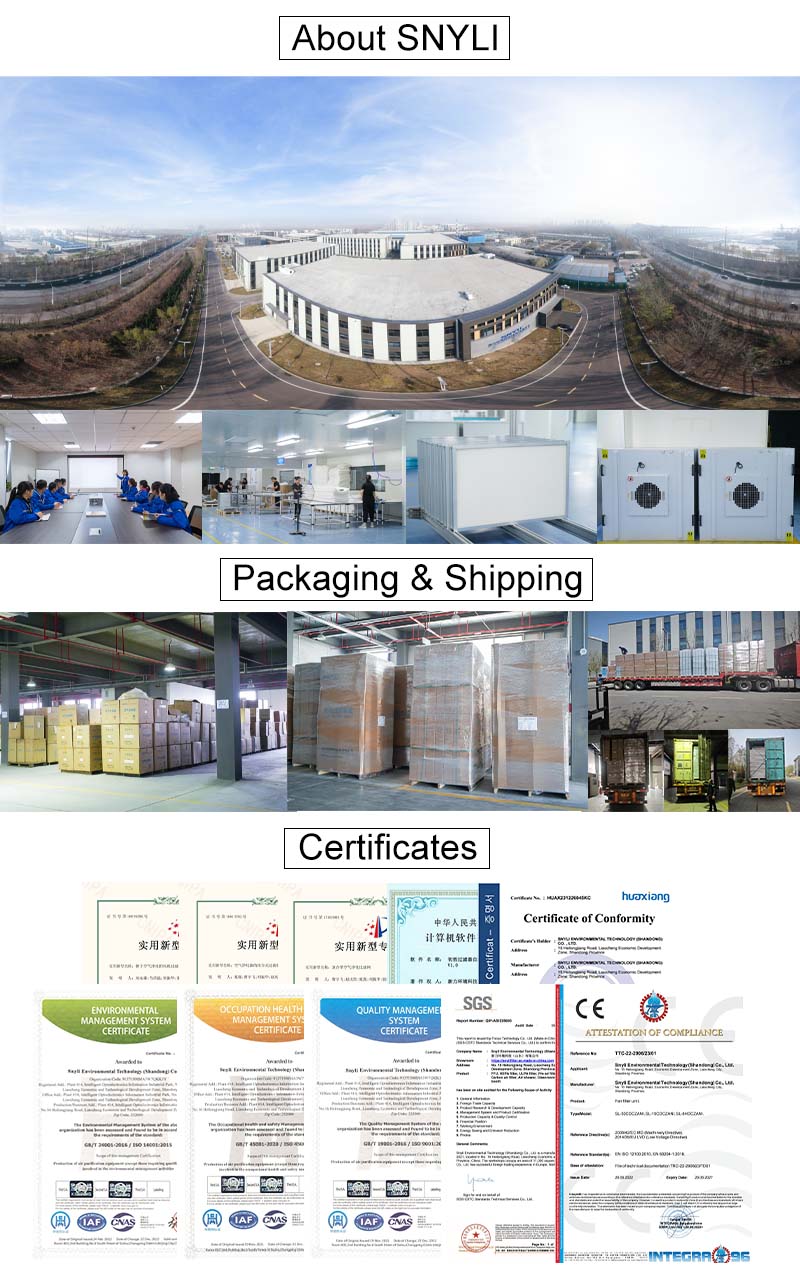

About us:

Snyli Environmental Technology (Shandong) Co.,Ltd has very rich experience in the development and production of air filtration products. For more than ten years, SNYLI has obtained many national patents and ISO/CE certificates, welcome to contact us anytime!

![Snyli Environmental Technology (Shandong) Co.,Ltd Snyli Environmental Technology (Shandong) Co.,Ltd]()